Tinplate For Crown Corks-CFX

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 Tons~25 Tons m.t.

- Supply Capability:

- 40000 MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General information of Tinplate For Crown Corks

|

Steel Type |

MR |

|

Temper (BA&CA) |

T1~T5, DR8 |

|

Coating |

2.8~8.4g/m2 |

|

Thickness & Tolerance |

0.15~0.5mm (Tolerance:±0.01mm) |

|

Width & Tolerance |

600~1000 mm(Tolerance: +2/-0mm) |

|

I.D |

508 MM |

|

Coil Weight |

3~10 MT |

|

Passivation |

311 |

|

Oiling |

DOS |

|

Surface Finish |

Bright ,Stone ,Silver ,Matte |

|

Min Order |

25 Tons for 1 20 feet FCL |

|

Package |

Seaworthy Export Standard Wooden Pallet |

|

Standard Available |

GB/T2520-2000, JIS G3303, ASTM A623, BS EN10202 |

|

Lead Time |

35 days after receiving buyer's original L/C or Prepayment |

|

Special specifications are available on customers' requirements. | |

Technical data of Tinplate For Crown Corks

|

Chemical Composition(%) |

Mechanical Property |

|

C:0.02~0.04 |

Yield Strength: (Mpa):280~320 |

|

Si:0.01~0.03 |

TensileStrength: (Mpa):340~390 |

|

Mn:0.18~0.22 |

Elongation:20%~30% |

|

P:0.014~0.016 |

------------- |

|

S:0.006~0.009 |

Application of Tinplate For Crown Corks

Tinplate is widely used for making all types of containers such as artistic cans, tea cans, painting cans,

chemical package cans and metal printing etc. Its applications are not limited to containers; recently,

tinplate has also been used for making electrical machinery parts and many other products.

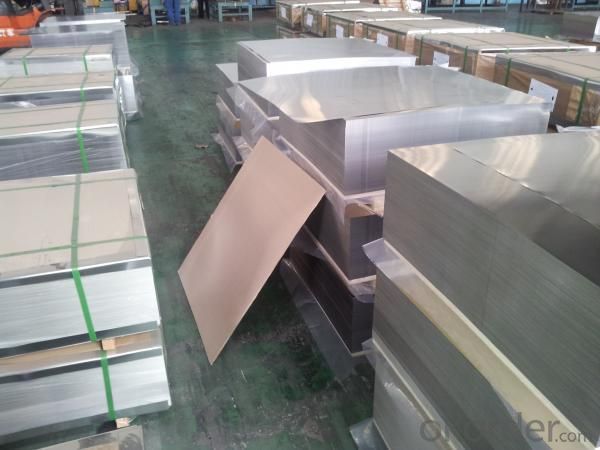

Equipment and Facility

Tin Coating Line

Cold Rolling Mill Batch Annealing Furnaces

Cutting Line Stock Area

Quantity Control System

- Q: How does tinplate contribute to the safety and integrity of packaged products?

- Tinplate contributes to the safety and integrity of packaged products by providing a protective barrier against external factors such as moisture, light, and oxygen. This helps to prevent the deterioration and contamination of the packaged goods, ensuring their quality and extending their shelf life. Additionally, tinplate is a durable and sturdy material that offers excellent resistance to impact and mechanical damage, safeguarding the contents during transportation and handling.

- Q: And what are the main packing materials?

- Currently on the market and it is mainly two kinds of packaging: PET plastic bottles and cans cans of Maguchi Tetsumi.Pet Chinese means: polybutylene terephthalate mainly consists of polyethylene terephthalate, two ester PET and polybutylene terephthalate Ding Erzhi PBT. Polyethylene terephthalate is also commonly known as polyester resin, commonly known as polyester resin. It is a condensation of terephthalic acid with ethylene glycol and is collectively referred to as thermoplastic polyester, or saturated polyester, with PBT.

- Q: What are the common sizes and shapes of tinplate containers?

- Common sizes and shapes of tinplate containers include round cans, rectangular tins, and square boxes. The sizes of these containers can vary, but some standard sizes include 8-ounce, 16-ounce, and 32-ounce cans.

- Q: How to quickly distinguish tinplate and ordinary substrate iron?

- Tinplate is the substrate, iron tin plating, tin bright, the substrate is dark, the substrate for a few days rust, and the two put together, the difference is great.

- Q: What are the different ways to seal tinplate containers?

- There are several different ways to seal tinplate containers, including using a metal lid with a rubber gasket, using a plastic or paper lid with a heat-sealed lining, using a twist-off cap with a tamper-evident seal, and using a peel-off foil seal.

- Q: Cookies with tinplate packaging has what advantage?

- Mature technology and high production efficiency: the production of tinplate has a long history, mature technology is a set of production equipment with matching, high production efficiency, can meet a variety of product packaging needs.

- Q: What are the main applications of tinplate in the music industry?

- Tinplate is primarily used in the music industry for the production of cans for storing and preserving musical instruments, such as drums and cymbals. It provides a durable, corrosion-resistant and lightweight solution for packaging and transporting these instruments, ensuring their protection and longevity. Additionally, tinplate is also used for manufacturing components of musical instruments, such as reeds for woodwind instruments or small parts for stringed instruments, due to its malleability and ability to create intricate shapes.

- Q: Can tinplate be used for cosmetic packaging?

- Yes, tinplate can be used for cosmetic packaging. Tinplate is a durable and versatile material that provides excellent protection for cosmetic products. Its resistance to corrosion and ability to maintain product integrity make it suitable for packaging various cosmetic items such as creams, lotions, and powders. Additionally, tinplate can be easily printed and decorated, allowing brands to create attractive and visually appealing packaging designs.

- Q: Can tinplate be used for packaging of non-food products?

- Yes, tinplate can be used for packaging of non-food products. Tinplate is a versatile material that offers excellent durability and corrosion resistance, making it suitable for a wide range of packaging applications including cosmetics, chemicals, and industrial products.

- Q: Can tinplate be used for packaging fragile items?

- Yes, tinplate can be used for packaging fragile items. Tinplate is a durable material that provides good protection against external impacts and can be molded into various shapes to provide a secure packaging solution for fragile items.

1. Manufacturer Overview

| Location | Hebei,China |

| Year Established | 2006 |

| Annual Output Value | Above US$100 Million |

| Main Markets | Singapore;Belgium |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 240,000 square meters |

| No. of Production Lines | Above 11 |

| Contract Manufacturing | |

| Product Price Range | High;Average |

Send your message to us

Tinplate For Crown Corks-CFX

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 Tons~25 Tons m.t.

- Supply Capability:

- 40000 MT Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords