Electrical Tinplate For Food Cans & Industrial Cans

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Usage

Tinplate is widely used for making all types of containers, containing industrial usage such as paint can, oil can, aerosol cans etc., and food cans like milk powder cans, tomato paste can, dry food cans etc.

2. Quality

As a state owned company and a large tinplate supplier in China, our tinplate quality ranks 1st level in China, similar to Bao Steel, Posco etc.

3. Specification

standard: GB/T2520, JIS G3303, DIN EN10202

Material: MR /SPCC

Thickness available: 0.16-0.50MM

Width available: 600~1050MM

Temper grade: T1 – DR8

Tin coating: ordinary 2.8g/2.8g, 5.6g/5.6g and others

Package: sea worthy export package.

Applications: Tin can for chemicals & paint cans, industrial cans, food cans

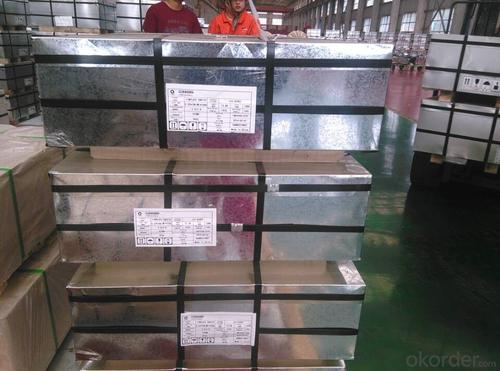

4. Our factory photo & equipments

5. Our Markets:

now our tinplate has been sold to more than 50 countries, including Europe country, Gulf Area, South American, South Afric etc.

6. Our Overseas Wareouses:

Furthermore, in the year 2014, we have more than 10 overseas warehouses all over the word, located in KSA, UAE, Oman, Russia, Kuwait, Qatar, Oman, Chile, Brazil etc.

7. FAQ

a. what's the annual output?

about 500,000 tons per year.

b. where's the raw matrial from?

our hot rolled coil is purchased from Capital Steel and other state owned mill, with quite good quality.

c. how long is the delivery time?

normally for SPCC about 45~55 days, while 65~75 days for MR material

d. how to control the quality during production process?

inside our workshop, we have MES syestem. It realizes the optimization of the production procedure in the workshop. It could record each step of the whole production procedures, and if some problem appears, factory could easily found and take action, it’s quite helpful to monitor and control the quality.

- Q: How does tinplate contribute to the resistance of marine equipment?

- Tinplate contributes to the resistance of marine equipment by providing a protective coating that helps prevent corrosion and oxidation caused by exposure to saltwater and other harsh marine environments.

- Q: How does tinplate contribute to the durability of stationery products?

- Tinplate contributes to the durability of stationery products by providing a protective and corrosion-resistant coating. This coating helps prevent rust and damage from moisture, ensuring that the stationery items remain in good condition for a longer period of time. Additionally, tinplate's strength and rigidity enhance the overall durability of stationery products, making them less prone to bending, crushing, or breaking during use or transportation.

- Q: How is tinplate coated for corrosion resistance?

- Tinplate is coated for corrosion resistance through a process called electrolytic tinning. This involves immersing the tinplate in a bath containing a tin salt solution and passing an electric current through it. The electric current causes tin ions to bond with the surface of the tinplate, forming a thin layer of tin that acts as a protective barrier against corrosion.

- Q: What are the different forms and shapes tinplate can be manufactured into?

- Tinplate can be manufactured into various forms and shapes, including cans, containers, boxes, trays, and even decorative items. Its malleability allows for complex designs, making it suitable for a wide range of applications in the packaging industry.

- Q: What is the cost of tinplate?

- The cost of tinplate varies depending on factors such as market demand, size, thickness, and quality.

- Q: What are the main technological advancements in tinplate production?

- Some of the main technological advancements in tinplate production include the development of high-speed production lines, automated processes for coating and printing, advancements in tin coating technology for improved corrosion resistance, and the integration of digital systems for quality control and traceability. Additionally, innovations in recycling and sustainability practices have also emerged, enabling more efficient use of resources and reducing environmental impact in tinplate production.

- Q: How does tinplate packaging contribute to product freshness?

- Tinplate packaging contributes to product freshness by providing a hermetically sealed and protective barrier against external elements such as moisture, air, and light. This helps to preserve the quality, flavor, and aroma of the product over a longer period of time, ensuring that it reaches consumers in its original state. Additionally, tinplate packaging is resistant to corrosion, preventing any potential contamination that could compromise the freshness of the product.

- Q: 0.25mm which melting point is low in tin plate and tin plate?

- Tin plated steel sheet and strip, also known as tinplate, the steel plate (belt) surface tin plated, has good corrosion resistance, non-toxic, can be used as packaging material cans, inside and outside the cable sheath, telecommunications instrument parts, flashlight and other hardware.

- Q: How is tinplate affected by exposure to UV light?

- Tinplate is generally not affected by exposure to UV light as it is a highly durable and corrosion-resistant material. However, prolonged exposure to intense UV radiation may cause minor color fading or surface discoloration over an extended period of time.

- Q: What are the benefits of using tinplate for coins?

- Tinplate offers several benefits when used for coins. Firstly, tinplate is highly durable, making it resistant to corrosion and wear, ensuring the longevity of the coins. Additionally, tinplate is easily moldable, allowing for intricate designs and detailed engravings on the coin's surface. Moreover, tinplate is a cost-effective material, making it an affordable choice for coin production. Lastly, tinplate is also lightweight, making it convenient for handling and transportation.

Send your message to us

Electrical Tinplate For Food Cans & Industrial Cans

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords