Tinplates and Tin Free Steel for Metal Packaging

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

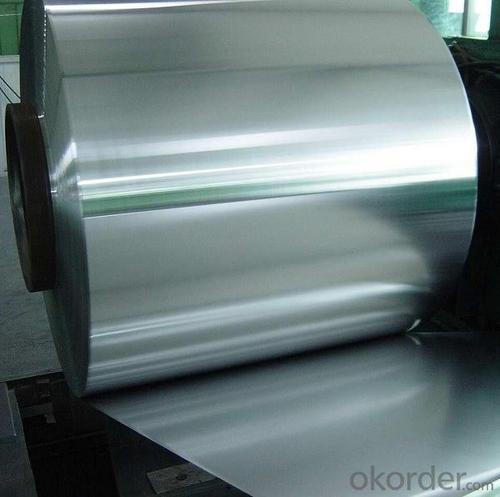

Tinplates and Tin Free Steel for Metal Packaging

Specifications

Prime electrical tinplate:

Thickness: 0.15 to 0.50mm

Width: 600 to 1010mm

Temper grade: BA and CA

For metal packaging usage

The Tinplate specification as following:

1, Reference standard: GB2520-88, JIS G3303-1997 and DIN EN10203-91

2, Material: MR, SPCC

3, Thickness available: 0.15mm to 0.50mm

4, Width available: 600mm to 1010 mm

5, Temper grade: T1 - T5 BA and CA both.

6, Tin coating: ordinary 2.8g/2.8g, 5.6g/5.6g, We also can produce according to customers' requests

7,Coil diameter: ID 420/ 508mm, OD from 1,000 to 1,250mm

8,Package: Anti-rust paper,corner protected. by sheet or coils according customer's require.

9, Applications: metal package usage like paint, chemical can,aerosol can and different food can production,

Also battery,electric cable and other industries

| Tinplate specifications | |||

| Steel Type | SPCC, MR | ||

| Temper(BA&CA) | T1~T5 | ||

| Coating | 1.1~11.2g/m2 | ||

| Thickness and tolerance | 0.15~0.50mm(Tolerance: _+0.01 mm) | ||

| Width & tolerance | 300~1000mm (Tolerance: 0~3mm) | ||

| Cut length & tolerance | 450~``50mm (Tolerance: 0~3mm ) | ||

| Coil inside diameter | 420/508mm | ||

| Coil Weight | 3~10 MT | ||

| Passivation | 311 | ||

| Oiling | DOS | ||

| Surface Finish | Bright, Stone, Silver, Matte | ||

| Packaging | Seaworthy Standard with wooden pallet | ||

| Standards Available | GB/T2520, JIS G3303, ASTM A623M & EN10202 | ||

| Special specitications are available on request. | |||

| Tin coating weight | |||

| Type | Designation of tin coating weight | Min.average tin coating weight(g/m2) | Former Coating Designation |

| Equal tin coating | 1.4/1.4 | 1.2/1.2 | #15 |

| 2.2/2.2 | 2.0/2.0 | #20 | |

| 2.8/2.8 | 2.45/2.45 | #25 | |

| 5.6/5.6 | 5.05/5.05 | #50 | |

| 8.4/8.4 | 7.55/7.55 | #75 | |

| 11.2/11.2 | 10.1/10.1 | #100 | |

| Differentially Coating | 1.4/2.8 | 1.2/2.45 | #15/25 |

| 2.2/2.8 | 2.2/2.45 | #20/25 | |

| 2.8/5.6 | 2.45/5.05 | #25/50 | |

| 2.8/8.4 | 2.45/7.55 | #25/75 | |

| 2.8/11.2 | 2.45/10.1 | #25/100 | |

| 5.6/8.4 | 5.05/7.55 | #50/75 | |

| 5.6/11.2 | 5.05/10.1 | #50/100 | |

| 8.4/11.2 | 7.55/10.1 | #75/100 | |

| Surface finish | |||

| Surface finish | Nominal surface roughness (um Ra) | Characteristic | |

| Bright finish | ≤Q0.35 | Glazed surface obtained after melting treatment of electrotinned smooth raw materail strip with extremely fine rubstone fingure by processing. | |

| Stone finish | 0.25~0.60 | Glazed surface obtained after melting treatment of electrotinned smooth raw materail stripfeaturing certain rubstone figures. | |

| Silver finish | 0.50~1.00 | Glazed surface obtained after melting treatment of electrotinned smooth raw material strip with rough matt furface. | |

| Matte finish | 0.80~2.50 | Matt surface of general matt raw material strip without melting treatment. | |

- Q: What is the shelf life of tinplate canned goods?

- The shelf life of tinplate canned goods can vary depending on the specific product and storage conditions. However, in general, properly stored tinplate canned goods can have a shelf life ranging from 1 to 5 years. It is important to check the expiration date and follow proper storage guidelines to ensure the quality and safety of the canned goods.

- Q: Can tinplate be used for kitchenware?

- Yes, tinplate can be used for kitchenware. Tinplate is a type of steel coated with a thin layer of tin, which provides protection against corrosion and enhances its aesthetics. It is commonly used for making cans, containers, and other kitchen utensils like bowls, trays, and cooking pans. Tinplate is durable, easy to clean, and resistant to rust, making it suitable for various kitchen applications.

- Q: How does tinplate perform in terms of moisture resistance?

- Tinplate performs exceptionally well in terms of moisture resistance. The tin coating on the steel substrate acts as a barrier, preventing moisture from coming into contact with the metal and causing corrosion. This makes tinplate highly suitable for packaging applications where moisture protection is crucial, ensuring the preservation and integrity of the contents.

- Q: Can tinplate packaging be used for electronic products?

- Yes, tinplate packaging can be used for electronic products. Tinplate is a durable and corrosion-resistant material that provides effective protection for electronic devices. It can be customized to fit various shapes and sizes, ensuring a secure and reliable packaging solution for electronic products. Additionally, tinplate packaging can also enhance the aesthetic appeal of electronic products, making them more visually appealing to consumers.

- Q: What are the main regulations governing tinplate recycling?

- The main regulations governing tinplate recycling vary by country and region. However, some common regulations include waste management laws, recycling targets, and regulations regarding the collection, sorting, and processing of tinplate materials. These regulations aim to promote the proper disposal and recycling of tinplate, ensuring environmental sustainability and resource conservation.

- Q: How does tinplate contribute to the efficiency of energy systems?

- Tinplate contributes to the efficiency of energy systems by providing a highly durable and corrosion-resistant material for the production of energy-efficient appliances, such as refrigerators and air conditioners. Its excellent thermal conductivity properties also aid in the efficient transfer of heat, reducing energy waste. Additionally, tinplate is widely used in the packaging of food and beverages, helping to preserve products and extend their shelf life, thus reducing food waste and energy consumption associated with production and transportation.

- Q: What are the potential health risks associated with tinplate?

- The potential health risks associated with tinplate are primarily due to the possibility of tin and other metals leaching into food or beverages stored in tinplate containers. Some studies suggest that high levels of tin exposure may lead to stomach and intestinal issues, such as nausea, vomiting, and diarrhea. However, the overall health risks are considered low, as strict regulations and safety measures are in place to minimize these concerns.

- Q: Is it necessary for the two cold rolling in the process of tinplate production, such as tempering and cold rolling (also called flatness)?

- The leveling process is only to change the yield platform or to improve the plate shape. Under normal pressure is very small, can not be considered cold rolled in the true sense.

- Q: How does tinplate packaging contribute to product aesthetics?

- Tinplate packaging contributes to product aesthetics by offering a visually appealing and versatile option for packaging. Its shiny and reflective surface adds a premium and luxurious look to products, enhancing their overall aesthetic appeal. Additionally, tinplate packaging can be easily customized through various printing techniques, enabling brands to create eye-catching designs, logos, and graphics that attract consumers' attention on store shelves. Its durability and ability to maintain color and shape also ensure that the product's aesthetic appeal remains intact throughout its lifespan.

- Q: What are the different ways to recycle tinplate closures?

- There are several different ways to recycle tinplate closures. One option is to separate the tinplate closures from other recyclable materials, such as glass or plastic bottles, and send them to a recycling facility where they can be melted down and reused to make new products. Another option is to repurpose tinplate closures for crafts or DIY projects, such as creating decorative magnets or jewelry. Additionally, some communities offer recycling programs specifically for tinplate closures, where they can be collected and reused in various ways.

Send your message to us

Tinplates and Tin Free Steel for Metal Packaging

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords