Prime ETP Tinplate for Metal Packaging of Dry Food

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 200000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Prime Electrical Prime ETP Tinplate for Metal Packaging (Manufacturer) Description

Due to Tinplate packaging`s good seal, nature, dark, robustness and unique decorative metal charm, it has a wide range of coverage in the packaging container industry,and common international packaging varieties. With a variety of CC tinplate material, DR materials, chrome plated and constantly enrich and promotion and development of packaging products and technology, tinplate packaging has promoted with innovation.

Because of its strong antioxidant and diverse styles, beautifully printed, tinplate containers are very popular and loved by customers, and they are widely used in food packaging, pharmaceutical packaging, commodity packaging, instrumentation, packaging, industrial packaging and so on.

Tinplate packaging has high strength, good formability, and many advantages, such as its compatibility in the international market. Therefore, tinplate packaging container is the largest amount of sheet metal packaging in the world.

2.Main Features of the Prime Electrical Prime ETP Tinplate for Metal Packaging (Manufacturer)

Appearance – Electrolytic Tin Plate is characterized by its beautiful metallic luster. Products with various kinds of surface roughness are produced by selecting the surface finish of the substrate steel sheet.

Paintability and printability – Electrolytic Tin Plates have excellent paintability and printability. Printing is beautifully finished using various lacquers and inks.

Formability and strength – Electrolytic Tin Plates have got very good formability and strength. By selecting a proper temper grade, appropriate formability is obtained for different applications as well as the required strength after forming.

Corrosion resistance – Tinplate has got good corrosion resistance. By selecting a proper coating weight, appropriate corrosion resistance is obtained against container contents. Coated items should meet 24 hour 5 % salt spray requirement.

Solderability and weldability – Electrolytic Tin Plates can be joined both by soldering or welding. These properties of tinplate are used for making various types of cans.

Hygienic – Tin coating provides good and non toxic barrier properties to protect food products from impurities, bacteria, moisture, light and odours.

Safe – Tinplate being low weight and high strength makes food cans easy to ship and transport.

Eco friendly – Tinplate offers 100 % recyclability.

Tin is not good for low temperature applications since it changes structure and loses adhesion when exposed to temperatures below – 40 deg C.

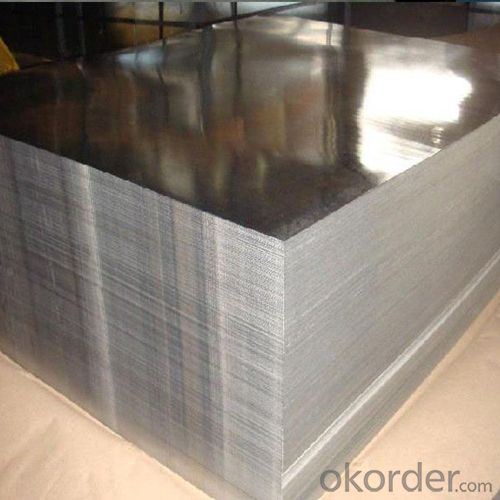

3.Prime Electrical Prime ETP Tinplate for Metal Packaging (Manufacturer) Images

4.Prime Electrical Prime ETP Tinplate for Metal Packaging (Manufacturer) Specification

Standard | ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

|

Material | MR,SPCC |

Thickness | 0.15mm - 0.50mm |

Width | 600mm -1150mm |

Temper | T1-T5 |

Annealing | BA & CA |

Coil Inner Diameter | 508mm |

Weight | 6-10 tons/coil 1~1.7 tons/sheets bundle |

Passivation | 311 |

Oil | DOS |

Surface | Finish,bright,stone,matte,silver |

5.FAQ of Prime Electrical Prime ETP Tinplate for Metal Packaging (Manufacturer)

- How are the Electrolytic Tin Plates specified?

The Electrolytic Tin Plates are specified as per the steel base, extent of tempering, the coating weight, annealing method and the surface finish.

- How many types there are for base steels?

The base steels are of three types: Type MR, L, D

-What your tinplate material is used for ?

Tinplate is widely used for the packaging of products. Such as food cans,

beverage cans, pet cans, closures, general line cans and so on.

Printed Tinplate is offered!!

-How to place .an order or contact you ?

Please send us Email. we will give you a quick response in seconds .

- How is your quality ?

All our quality is prime even the secondary quality . We have many years experience

In this field with serious quality control standard . Advanced equipment, We welcome your visit to our factory .

- Q: What are the characteristics of different tin process

- Good mechanical properties: tinplate cans relative to other containers, such as plastic, glass, paper containers and strength, and good rigidity, it is not easy to break. It is not only used for small sale packing, but also the main container for large transportation package. 2.: excellent barrier tin barrier properties than any other materials are excellent, gas barrier properties, moisture resistance, shading and aroma were good, and the sealing is reliable, reliable protection products.

- Q: How does tinplate perform in terms of light protection?

- Tinplate offers excellent light protection due to its opaque and reflective nature, effectively blocking out light and preventing its transmission through the material.

- Q: How does tinplate packaging impact brand image and perception?

- Tinplate packaging can have a positive impact on brand image and perception. It is often associated with high quality and premium products, which can enhance the perceived value of the brand. Tinplate packaging also offers a luxurious and retro charm, appealing to consumers who value aesthetics and nostalgia. Additionally, tinplate packaging can provide better protection for products, ensuring their freshness and quality, which further enhances the brand's reputation. Overall, tinplate packaging can contribute to a positive brand image and create a favorable perception among consumers.

- Q: What are the different types of tinplate coatings?

- The different types of tinplate coatings include electrolytic tinplate (ETP), tin-free steel (TFS), and black plate.

- Q: Can tinplate be used for medical or pharmaceutical packaging?

- Yes, tinplate can be used for medical or pharmaceutical packaging. Tinplate is a durable and corrosion-resistant material that provides an excellent barrier against moisture, light, and oxygen, which is crucial for preserving the quality and integrity of medical or pharmaceutical products. Additionally, tinplate's ability to be sterilized makes it suitable for packaging items that require a high level of hygiene.

- Q: Can tinplate be used for packaging products with sharp edges?

- Yes, tinplate can be used for packaging products with sharp edges. Tinplate is known for its durability and strength, making it suitable for packaging products that have sharp edges without causing any damage to the packaging material.

- Q: Can tinplate be used for packaging of corrosive substances?

- No, tinplate cannot be used for packaging of corrosive substances as it is susceptible to corrosion itself.

- Q: What is the purpose of tinplate coating?

- The purpose of tinplate coating is to provide a protective layer of tin on steel or iron surfaces, which helps prevent corrosion and enhance the appearance of the metal.

- Q: How does tinplate perform in terms of insulation properties?

- Tinplate does not perform well in terms of insulation properties as it is a good conductor of heat and electricity.

- Q: How does tinplate affect the sound quality of musical instruments?

- Tinplate does not directly affect the sound quality of musical instruments. The sound quality primarily depends on the construction, materials, and design of the instrument itself, such as the type of wood used, the shape, and the craftsmanship. Tinplate may be used for aesthetic purposes or as a protective coating, but it does not significantly impact the sound produced by the instrument.

Send your message to us

Prime ETP Tinplate for Metal Packaging of Dry Food

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 200000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords