Tinplate for Chemical Packaging with Competive Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

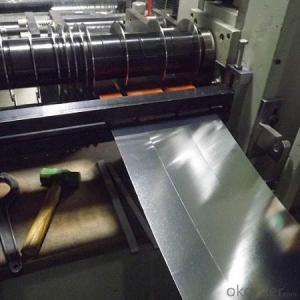

Tinplate for Food Pakcaging and Chemical Packaging

Specifications

Prime electrical tinplate:

Thickness: 0.15 to 0.50mm

Width: 600 to 1010mm

Temper grade: BA and CA

For metal packaging usage

The Tinplate specification as following:

1, Reference standard: GB2520-88, JIS G3303-1997 and DIN EN10203-91

2, Material: MR, SPCC

3, Thickness available: 0.15mm to 0.50mm

4, Width available: 600mm to 1010 mm

5, Temper grade: T1 - T5 BA and CA both.

6, Tin coating: ordinary 2.8g/2.8g, 5.6g/5.6g, We also can produce according to customers' requests

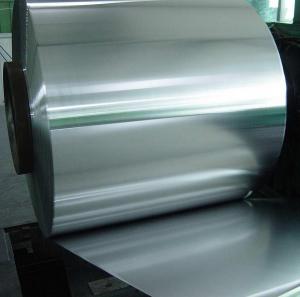

7,Coil diameter: ID 420/ 508mm, OD from 1,000 to 1,250mm

8,Package: Anti-rust paper,corner protected. by sheet or coils according customer's require.

9, Applications: metal package usage like paint, chemical can,aerosol can and different food can production,

Also battery,electric cable and other industries

| Tinplate specifications | |||

| Steel Type | SPCC, MR | ||

| Temper(BA&CA) | T1~T5 | ||

| Coating | 1.1~11.2g/m2 | ||

| Thickness and tolerance | 0.15~0.50mm(Tolerance: _+0.01 mm) | ||

| Width & tolerance | 300~1000mm (Tolerance: 0~3mm) | ||

| Cut length & tolerance | 450~``50mm (Tolerance: 0~3mm ) | ||

| Coil inside diameter | 420/508mm | ||

| Coil Weight | 3~10 MT | ||

| Passivation | 311 | ||

| Oiling | DOS | ||

| Surface Finish | Bright, Stone, Silver, Matte | ||

| Packaging | Seaworthy Standard with wooden pallet | ||

| Standards Available | GB/T2520, JIS G3303, ASTM A623M & EN10202 | ||

| Special specitications are available on request. | |||

| Tin coating weight | |||

| Type | Designation of tin coating weight | Min.average tin coating weight(g/m2) | Former Coating Designation |

| Equal tin coating | 1.4/1.4 | 1.2/1.2 | #15 |

| 2.2/2.2 | 2.0/2.0 | #20 | |

| 2.8/2.8 | 2.45/2.45 | #25 | |

| 5.6/5.6 | 5.05/5.05 | #50 | |

| 8.4/8.4 | 7.55/7.55 | #75 | |

| 11.2/11.2 | 10.1/10.1 | #100 | |

| Differentially Coating | 1.4/2.8 | 1.2/2.45 | #15/25 |

| 2.2/2.8 | 2.2/2.45 | #20/25 | |

| 2.8/5.6 | 2.45/5.05 | #25/50 | |

| 2.8/8.4 | 2.45/7.55 | #25/75 | |

| 2.8/11.2 | 2.45/10.1 | #25/100 | |

| 5.6/8.4 | 5.05/7.55 | #50/75 | |

| 5.6/11.2 | 5.05/10.1 | #50/100 | |

| 8.4/11.2 | 7.55/10.1 | #75/100 | |

| Surface finish | |||

| Surface finish | Nominal surface roughness (um Ra) | Characteristic | |

| Bright finish | ≤Q0.35 | Glazed surface obtained after melting treatment of electrotinned smooth raw materail strip with extremely fine rubstone fingure by processing. | |

| Stone finish | 0.25~0.60 | Glazed surface obtained after melting treatment of electrotinned smooth raw materail stripfeaturing certain rubstone figures. | |

| Silver finish | 0.50~1.00 | Glazed surface obtained after melting treatment of electrotinned smooth raw material strip with rough matt furface. | |

| Matte finish | 0.80~2.50 | Matt surface of general matt raw material strip without melting treatment. | |

- Q: What are the common sizes and thicknesses of tinplate?

- The common sizes of tinplate range from 0.14mm to 0.60mm in thickness, with typical widths varying from 600mm to 1200mm.

- Q: How does tinplate compare to stainless steel in terms of properties and applications?

- Tinplate and stainless steel have different properties and applications. Tinplate is a steel coated with a thin layer of tin, providing corrosion resistance and a shiny appearance. It is commonly used for packaging food and beverages, as it is lightweight and easily formed into cans. On the other hand, stainless steel is an alloy with high corrosion resistance and strength. It is widely used in various industries, including construction, automotive, and kitchen appliances, due to its durability and aesthetic appeal. While both materials offer corrosion resistance, stainless steel is generally stronger and more versatile, making it suitable for a wider range of applications compared to tinplate.

- Q: Can tinplate be welded or soldered?

- Yes, tinplate can be welded or soldered.

- Q: What are the weight advantages of using tinplate?

- One of the weight advantages of using tinplate is its lightweight nature. Tinplate is made by coating a thin layer of tin onto a steel substrate, resulting in a material that is significantly lighter than other packaging options such as glass or aluminum. This lightweight characteristic makes tinplate an ideal choice for various industries, including food and beverage, where weight reduction is essential for transportation, storage, and overall product cost efficiency.

- Q: How does tinplate packaging contribute to product portion control?

- Tinplate packaging contributes to product portion control by providing a durable and versatile material that can be easily shaped and sealed. This allows manufacturers to create smaller, individual-sized containers, which helps consumers monitor and limit their consumption. Additionally, tinplate packaging often includes clear labeling and measurement indicators, making it easier for consumers to accurately gauge their desired portion sizes.

- Q: Can tinplate be used for packaging hazardous materials?

- Yes, tinplate can be used for packaging hazardous materials. Tinplate is a durable and corrosion-resistant material that can effectively contain and protect hazardous substances. Additionally, it meets the necessary safety regulations for packaging such materials, making it a suitable choice for hazardous material packaging.

- Q: How to quickly open the bottle?

- Swiss Army knife, it has opened the canned fruits with tools under the hook can cover the exterior edge of front edge force canned fruit like a ring, groove cover on the edge of... The pressure inside a circle, do not pay attention to the head word screwdriver pressed in, or it may have wear. Under the hook can cover the exterior edge of front edge force under pressure can, like a ring groove on the side of the roof... Pressed in a circle, do not pay attention to the head word screwdriver pressed in, or you may wear. This tool is also very easy to use.

- Q: What are the different methods of reusing tinplate packaging?

- There are several ways to reuse tinplate packaging. One common method is to repurpose the packaging for storing small items like buttons, jewelry, or crafting supplies. Tinplate packaging can also be used as decorative containers for plants, candles, or as unique gift boxes. Additionally, tinplate packaging can be recycled and used to create new products, reducing waste and promoting sustainability.

- Q: What are the common quality standards for tinplate?

- The common quality standards for tinplate include factors such as the thickness and uniformity of the tin coating, the absence of defects like scratches or dents, the adhesion of the tin coating to the base metal, and the overall dimensional and mechanical properties of the tinplate.

- Q: Can tinplate be used in extreme temperatures?

- Yes, tinplate can be used in extreme temperatures. Tinplate is known for its excellent heat resistance properties, making it suitable for applications that require withstanding high temperatures.

Send your message to us

Tinplate for Chemical Packaging with Competive Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords