Tin Free Steel TFS for Twist-off Caps and Crown Caps

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

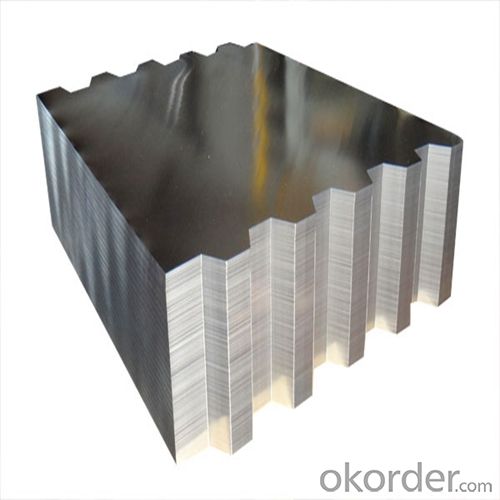

1.Structure of Tin Free Steel TFS for Twist-off Caps and Crown Caps Description

Tin Free Steel (TFS) is thin black plate with two coats; one of metal chrome film and the other of chromium oxide. TFS is ideal for the manufacturing of crowns, container ends & shallow drawn cans etc. TFS is also known as Chromium coated steel.

2.Main Features of the Tin Free Steel TFS for Twist-off Caps and Crown Caps

Also known as chromed steel, tin-free steel (TFS) is obtained by coating the metal base (low-carbon steel) with an ultra-thin layer of metallic chrome and then with a chromium oxide layer.

3.Tin Free Steel TFS for Twist-off Caps and Crown Caps Images

4.Tin Free Steel TFS for Twist-off Caps and Crown Caps Specification

Specification of :

Material: MR,SPCC

Thickness:0.15mm - 0.50mm

Width: 600mm -1150mm

Temper: T1-T5

Annealing: BA & CA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Oil: DOS

Surface: Finish,bright,stone,matte,silver

5.FAQ of Tin Free Steel TFS for Twist-off Caps and Crown Caps

-What is MOQ?

Our MOQ would be 25 tons.

- Do you only have prime quality TFS ?

We can supply both prime and second quality TFS.

- Q: What are the different ways to label tinplate packaging?

- There are several different ways to label tinplate packaging, including using adhesive labels, direct printing, embossing, lithography, and screen printing.

- Q: What are the weight advantages of using tinplate?

- Tinplate offers several weight advantages compared to other packaging materials. Firstly, it is significantly lighter than materials like glass or aluminum, making it easier to handle and transport. This lightweight nature also contributes to lower shipping costs. Additionally, tinplate's lightness allows for more product to be packaged in a smaller space, maximizing efficiency and reducing storage requirements. Overall, the weight advantages of tinplate make it a preferred choice for many industries seeking cost-effective and efficient packaging solutions.

- Q: How is the thickness of tinplate measured?

- The thickness of tinplate is typically measured using a specialized instrument called a micrometer. This handheld device allows for precise measurement of the tinplate thickness by exerting pressure on the surface and providing an accurate reading in millimeters or inches.

- Q: How is tinplate tested for quality and durability?

- Tinplate is tested for quality and durability through a series of methods including visual inspection, chemical analysis, thickness measurement, and corrosion resistance assessment. These tests ensure that the tinplate meets the required standards and can withstand various environmental conditions and handling processes.

- Q: What is the global demand for tinplate?

- The global demand for tinplate is significant and continuously growing. Tinplate is widely used in various industries such as packaging, electronics, automotive, and construction. Its corrosion resistance, durability, and versatility make it a preferred choice for packaging materials, especially in the food and beverage sector. With the increasing population and urbanization, the demand for tinplate is expected to further rise in the coming years, driven by factors like increasing consumer goods consumption and technological advancements.

- Q: How does tinplate perform in high humidity environments?

- Tinplate performs well in high humidity environments due to its exceptional corrosion resistance properties. The tin coating on tinplate acts as a protective barrier against moisture, preventing the underlying steel from rusting or corroding. This makes tinplate a reliable and durable option for packaging and other applications in high humidity conditions.

- Q: What are the different types of tinplate finishes?

- The different types of tinplate finishes include bright, matte, stone, lacquered, and printed finishes.

- Q: What are the challenges in printing on tinplate?

- Some of the challenges in printing on tinplate include the limited adhesion of ink to the smooth surface of tin, the need for specialized inks and printing techniques to ensure durability and resistance to scratching or fading, and the potential for contamination or damage to the tinplate surface during the printing process. Additionally, achieving precise color matching and maintaining consistent print quality can be challenging due to the reflective nature of the tin surface.

- Q: What are the main trends in tinplate recycling?

- The main trends in tinplate recycling include increased awareness and implementation of recycling programs, advancements in technology for efficient separation and processing of tinplate, and the growing demand for sustainable packaging solutions. Additionally, there has been a shift towards closed-loop recycling systems, where tinplate waste is recycled and used to produce new tinplate products, reducing the need for virgin materials.

- Q: How does tinplate compare to other packaging materials in terms of shelf appeal?

- Tinplate stands out among other packaging materials in terms of shelf appeal due to its unique combination of durability, versatility, and aesthetic appeal. Its shiny surface and smooth finish make products packaged in tinplate visually appealing, catching the attention of consumers. Additionally, tinplate allows for intricate and vibrant designs, enhancing the overall attractiveness of the packaging. Moreover, the robustness and long shelf life of tinplate ensure that the packaging remains intact, preserving the product's visual appeal throughout its lifespan.

Send your message to us

Tin Free Steel TFS for Twist-off Caps and Crown Caps

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords