Prime Good Quality Tin Free Steel and ETP for Crown Caps

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Prime Good Quality Tin Free Steel and ETP for Crown Caps Description

Tin Free Steel (TFS) is thin black plate with two coats; one of metal chrome film and the other of chromium oxide. TFS is ideal for the manufacturing of crowns, container ends & shallow drawn cans etc. TFS is also known as Chromium coated steel.

2.Main Features of the Prime Good Quality Tin Free Steel and ETP for Crown Caps

Appearance – Tinplate is characterized by its beautiful metallic luster. Products with various kinds of surface roughness are produced by selecting the surface finish of the substrate steel sheet.

Paintability and printability – Tinplates have excellent paintability and printability. Printing is beautifully finished using various lacquers and inks.

Formability and strength – Tinplates have got very good formability and strength. By selecting a proper temper grade, appropriate formability is obtained for different applications as well as the required strength after forming.

Corrosion resistance – Tinplate has got good corrosion resistance. By selecting a proper coating weight, appropriate corrosion resistance is obtained against container contents. Coated items should meet 24 hour 5 % salt spray requirement.

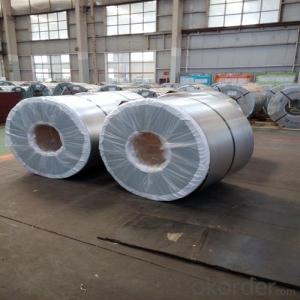

3.Prime Good Quality Tin Free Steel and ETP for Crown Caps Images

4.Prime Good Quality Tin Free Steel and ETP for Crown Caps Specification

Specification of :

Standard: ISO 11949 -1995, GB/T2520-2000,JIS G3303,ASTM A623, BS EN 10202

Material: MR,SPCC

Thickness:0.15mm - 0.50mm

Width: 600mm -1150mm

Temper: T1-T5

Annealing: BA & CA

Coil Inner Diameter: 508mm

Weight: 6-10 tons/coil 1~1.7 tons/sheets bundle

Passivation:311

Oil: DOS

Surface: Finish,bright,stone,matte,silver

5.FAQ of Prime Good Quality Tin Free Steel and ETP for Crown Caps

- How are the tinplates specified?

The tinplates are specified as per the steel base, extent of tempering, the coating weight, annealing method and the surface finish.

- How many types there are for base steels?

The base steels are of three types: Type MR, L, D

- Q: What are the different ways to recycle tinplate containers?

- There are several ways to recycle tinplate containers. One way is to separate the tinplate from other materials, such as plastic or paper, and then melt it down to be reused for manufacturing new tinplate products. Another method involves crushing the containers to reduce their size, which makes it easier to transport and process them at recycling facilities. Additionally, tinplate containers can be repurposed for various uses, such as storage or organization, before eventually being recycled.

- Q: How does tinplate handle exposure to different atmospheric conditions?

- Tinplate is known for its excellent resistance to atmospheric conditions. It is highly resistant to corrosion and can withstand exposure to different environmental factors, such as moisture, humidity, and temperature variations. The tin coating on the tinplate acts as a protective layer, preventing the base metal from coming into direct contact with the atmosphere and thus reducing the risk of rusting or oxidation. This makes tinplate a suitable material for various applications, including packaging, construction, and automotive industries, where it needs to withstand different atmospheric conditions.

- Q: Can tinplate be used for packaging household cleaning products?

- Yes, tinplate can be used for packaging household cleaning products. Tinplate is a durable and corrosion-resistant material that provides excellent protection and preservation for various types of products, including household cleaning solutions. It is commonly used in the manufacturing of cans and containers for packaging cleaning products due to its strength, versatility, and ability to maintain product quality.

- Q: Cookies with tinplate packaging has what advantage?

- Good mechanical properties: tinplate cans relative to other containers, such as plastic, glass, paper containers and strength, and good rigidity, it is not easy to break. It is not only used for small sale packing, but also the main container for large transportation package.

- Q: What is tinplate?

- Tinplate is a thin steel sheet coated with a layer of tin, which provides corrosion resistance and enhances its aesthetic appeal.

- Q: What are the main challenges in tinplate coil handling?

- The main challenges in tinplate coil handling include ensuring proper lifting and transportation techniques to avoid damage, managing the weight and size of the coils for safe handling, maintaining cleanliness to prevent contamination, and implementing efficient storage and inventory management systems. Additionally, coordinating with suppliers and customers to ensure timely delivery and minimizing transit damage are also significant challenges.

- Q: Can tinplate be used for packaging petrochemical products?

- Yes, tinplate can be used for packaging petrochemical products. Tinplate is a type of steel coated with a thin layer of tin, which provides excellent protection against corrosion and contamination. Its durability and resistance to chemical reactions make it suitable for safely containing and storing petrochemical products.

- Q: What are the main applications of tinplate in the stationery industry?

- Tinplate is commonly used in the stationery industry for various purposes such as making pencil boxes, pen holders, and storage containers. Its durability, lightweight nature, and ability to be molded into different shapes make it ideal for creating functional and aesthetically pleasing stationery products. Additionally, tinplate's ability to resist moisture and protect its contents from damage makes it a preferred choice for items like pencil sharpeners and paper clips.

- Q: What is the average lifespan of tinplate packaging?

- The average lifespan of tinplate packaging depends on various factors such as usage, storage conditions, and handling. However, tinplate packaging is known for its durability and longevity, and with proper care, it can last for several years or even decades.

- Q: How does tinplate perform in terms of mechanical strength and durability?

- Tinplate exhibits excellent mechanical strength and durability due to its composition of steel coated with a thin layer of tin. This combination enhances its resistance to corrosion, making it long-lasting and capable of withstanding various mechanical forces without compromising its structural integrity. Tinplate is renowned for its ability to retain its shape and withstand impacts, making it a reliable choice for packaging and other applications requiring high durability.

Send your message to us

Prime Good Quality Tin Free Steel and ETP for Crown Caps

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords