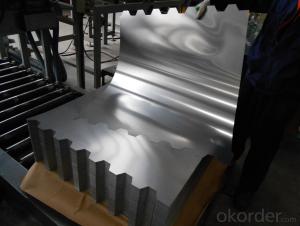

TFS TIN FREE STEEL

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Jiangsu Hefeng Steel New Material Co.,Ltd.started production in Nov.2009,with the total investment of 200 million Yuan.Our company covers an area of 68,000 square meters.The registered capital is 50 million Yuan.We are located in a port city-Dafeng City.

With our keen sense of market demands and continuous efforts,we introduce international advanced production equipment to contral product quality to keep in first class level.

Our main products are tinplate basal plates and chrome coated plates.We are also committed to developing other high-end products in this field.The annual production capacity is more than 100,000 tons.For iron caps,the annual production capacity is around 6-8 million tons.We can produce products in thickness of 0.1mm to 0.5mm.The longest width could be 1,000mm.

All of our products are used in beer both caps,beverage packaging(cans),chemicals,mobile shells,rice cookers,hardware,electronics,communication(fiber cables)and other areas to replace the imported high-grade tin(volume)board materials.

Our company will base on the market,hold on to the“quality of life”principle and let our customers enjoy our products.

- Q: How is tinplate used in the manufacturing of electronic devices?

- Tinplate is commonly used in the manufacturing of electronic devices as it provides an ideal material for the production of casing and outer components. Its corrosion-resistant properties help protect the internal circuitry from environmental factors, ensuring durability and longevity of the electronic device. Additionally, tinplate's malleability allows for easy shaping and customization, enabling manufacturers to create sleek and aesthetically pleasing designs.

- Q: How can recycled tin cans be recycled?

- Longhu white tin cans crusher is a company based on years of manufacturing experience carefully developed recovery special grinder, the crusher machine advantages in traditional variety, make full use of impact, shear, impact each other, grinding theory carefully developed.

- Q: Can tinplate be used for roofing and construction?

- Yes, tinplate can be used for roofing and construction purposes. Tinplate is a durable material that provides excellent corrosion resistance and is often used for roofing applications due to its ability to withstand various weather conditions. It is also commonly utilized in construction for cladding, wall panels, and other architectural elements.

- Q: How does tinplate packaging contribute to product protection against contamination?

- Tinplate packaging contributes to product protection against contamination by providing a durable and secure barrier between the product and external elements. The tin coating on the steel substrate prevents corrosion and rusting, ensuring the integrity of the packaging. This protects the product from moisture, oxygen, and other contaminants that could compromise its quality or safety. Additionally, tinplate packaging is airtight, preventing the entry of bacteria or microorganisms, further enhancing product protection against contamination.

- Q: How does tinplate packaging affect the shelf life of products?

- Tinplate packaging can significantly extend the shelf life of products due to its excellent barrier properties. It acts as a protective barrier against moisture, oxygen, light, and other external factors that can degrade or spoil the product. This prevents oxidation, moisture absorption, and bacterial growth, thereby preserving the quality, taste, and freshness of the contents for a longer period. Additionally, tinplate packaging also offers excellent durability and resistance to physical damage, ensuring that the product remains intact during transportation and storage, further contributing to its extended shelf life.

- Q: How does tinplate contribute to the safety of automotive components?

- Tinplate contributes to the safety of automotive components in several ways. Firstly, tinplate is highly resistant to corrosion, which helps protect automotive components from rust and deterioration. This ensures that critical parts, such as brake lines or fuel tanks, remain in good condition, reducing the risk of failure and potential accidents. Additionally, tinplate's strength and durability make it suitable for impact-sensitive components, like car body panels or engine parts, providing an extra layer of protection in case of collisions. Lastly, tinplate's ability to withstand high temperatures and its fire resistance properties make it an ideal material for automotive components that may be exposed to extreme heat or fire hazards, further enhancing safety in the event of accidents or emergencies.

- Q: Can tinplate be used for aerosol cans?

- Yes, tinplate can be used for aerosol cans. Tinplate is a commonly used material for making aerosol cans due to its durability and ability to resist corrosion. It also provides a barrier against oxygen, moisture, and light, ensuring the contents of the aerosol can remain protected.

- Q: Can tinplate packaging be used for pet care products?

- Yes, tinplate packaging can be used for pet care products. Tinplate is a durable and versatile material that provides excellent protection against moisture, light, and oxidation. It can be easily shaped and decorated, making it suitable for packaging various pet care items such as food, treats, supplements, and grooming products. Additionally, tinplate packaging is recyclable, making it an environmentally friendly choice for pet owners.

- Q: How does tinplate packaging contribute to product tamper resistance?

- Tinplate packaging contributes to product tamper resistance by providing a strong and durable barrier that is difficult to manipulate or breach without leaving visible signs of tampering. Its sturdy construction and sealed nature make it harder for unauthorized individuals to access the product, ensuring its integrity and safety.

- Q: How does the printing process affect the durability of tinplate?

- The printing process can significantly affect the durability of tinplate. It forms a protective layer on the surface of the tinplate, making it more resistant to corrosion and external factors that may cause damage. The printing process also enhances the tinplate's scratch resistance, ensuring that the printed design remains intact for a longer period. Additionally, the printing process can provide an extra layer of insulation, protecting the tinplate from heat and moisture, further increasing its durability.

Send your message to us

TFS TIN FREE STEEL

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords