Tin Free Steel for Crown Caps for Food Packaging

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Products: Tin Free Steel

Tinplate and TFS are widely used for making all types of containers such as artistic cans, tea cans, painting cans, chemical package cans and metal printing etc. Its applications are not limited to containers; recently, they have also been used for making electrical machinery parts and many other products.

2. Specification:

Our goods enjoyed high quality both at home and abroad. We can supply tin free steel as follows:

Technical standard | JISG3315 and GB/T24180 - 2009 (BS EN 10202:1990) |

Steel Type | MR / SPCC |

Thickness | From 0.15mm to 0.50mm (Tolerance +/- 0.01mm) |

Width | Normally 600-1050mm (Tolerance +3/-0 mm) |

Coating | Total chromium min 30mg/m2 max 140mg/m2 |

Temper & Annealing | T1-T5, DR7-8, TS230-TH435, T49-T65(+/- 4) |

Surface Treatment | Bright & Fine Stone & Stone & Silver & Matt |

Payment terms | Letter of Credit (L/C), Telegraphic transfer (T/T) |

Price terms | CFR & CIF price term |

Delivery time | Within 60 days after received L/C or T/T down payment |

Packing | High quality shipping packing which contains thin plastic film, rust-proof paper, metal cover, metal angles and strap sand pallet. |

Minimum order Quantity(MOQ) | 25 metric tons (1X 20'' container) |

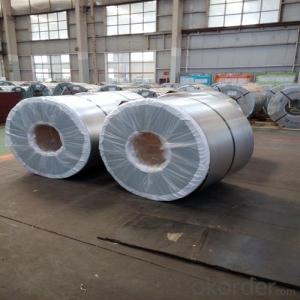

3. Pictures:

4. Features of the factory price/ tin free steel/tinplate/tfs/tmbp/etp/spte:

Beautiful Appearance

Excellent Paintability & Printability

Excellent Formability & Strength

Excellent Corrosion Resistance

Excellent Solderability & Weldability

5. FAQ:

We are one of the main producers in China for tinplate, tin free steel and also TMBP. At present, our productivity is more than 450000 MT/year.

For more information about our products or company, pls contact us freely.

- Q: How is tinplate affected by exposure to light?

- Tinplate is not significantly affected by exposure to light. It is a durable material that can withstand various environmental conditions, including light exposure, without any major changes or deterioration.

- Q: How is tinplate coated with organic coatings?

- Tinplate is coated with organic coatings through a process called electrolytic deposition. This involves immersing the tinplate in an electrolyte solution and passing an electric current through it. The organic coating materials, typically polymers or resins, are dissolved in the electrolyte solution and are attracted to the charged surface of the tinplate. As the electric current passes through, the organic coating materials are deposited onto the tinplate, forming a protective layer.

- Q: What are the common thicknesses of tinplate?

- The common thicknesses of tinplate range from 0.13mm to 0.49mm, with the most commonly used thicknesses being 0.18mm, 0.20mm, and 0.23mm.

- Q: Can tinplate be used for cosmetic packaging?

- Yes, tinplate can be used for cosmetic packaging. Tinplate is a popular material choice for packaging cosmetics due to its durability, corrosion resistance, and ability to retain product integrity. It also offers a premium look and feel, making it suitable for high-end cosmetic brands.

- Q: What are the regulations and standards related to tinplate packaging?

- Regulations and standards related to tinplate packaging may vary depending on the specific country or region. However, in general, tinplate packaging is subject to regulations and standards related to food safety, product labeling, and environmental concerns. These regulations ensure that tinplate packaging materials are safe for food contact and that they comply with specific guidelines for packaging materials. Additionally, there may be standards regarding the thickness, coating, and overall quality of tinplate packaging to ensure its durability and performance.

- Q: Can tinplate be used for packaging pet food?

- Yes, tinplate can be used for packaging pet food. Tinplate is a popular choice for food packaging due to its durability, corrosion resistance, and ability to protect against light, oxygen, and moisture. It is commonly used for canned goods, including pet food, as it helps to maintain the freshness and quality of the product.

- Q: What are the main challenges in tinplate recycling?

- One of the main challenges in tinplate recycling is the separation of tin coating from the steel substrate, as the two materials have different melting points. Additionally, the presence of other contaminants such as lacquers and coatings on the tinplate can complicate the recycling process. Furthermore, the collection and sorting of tinplate waste can be challenging due to its prevalence in various product packaging, making it difficult to streamline the recycling system. Overall, technological advancements and increased awareness are necessary to overcome these challenges and improve the efficiency of tinplate recycling.

- Q: Tin, tin plated iron. Why can't we get white wine?

- Passivation of the tinplate, if further coating, will be very good corrosion resistance, but these coatings are not resistant to alcohol.In short, tinplate is afraid of water, but also afraid of alcohol, so it can not be loaded white wine.

- Q: Can tinplate be used for ammunition?

- Yes, tinplate can be used for ammunition. It is commonly used for shotgun shells and some types of small caliber ammunition. Tinplate provides durability and corrosion resistance, making it suitable for preserving the integrity of ammunition during storage and transportation.

- Q: How does tinplate perform in terms of durability and longevity?

- Tinplate is known for its exceptional durability and longevity. The tin coating provides excellent corrosion resistance, preventing the metal underneath from rusting or deteriorating. This makes tinplate highly suitable for packaging purposes, as it can protect the contents for an extended period. Additionally, tinplate's sturdy construction ensures it can withstand mechanical stress and maintain its integrity over time, further enhancing its durability and longevity.

Send your message to us

Tin Free Steel for Crown Caps for Food Packaging

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords