Prime Quality Tin Free Steel for Twist-off Caps Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Prime Quality Tin Free Steel for Twist-off Caps Use Description

The product complies with ASTM A-657 Specification and is manufactured with low current density (TFS-III) and is supplied only in coils of up to 12 metric tons.

2.Main Features of the Prime Quality Tin Free Steel for Twist-off Caps Use

Paint Adhesion : TFS possesses better paint adhesion properties, thus making it ideal for DRD cans and adhesive bonded cans.

Weldability: TFS can be welded when metallic coating layers are removed by edge grinding.

TFS should be Lacquered / Coated to prevent rust in humid condition.

Internal Coating / Lacquering can be avoided in the case of TFS used to store motor oil or cooking oil.

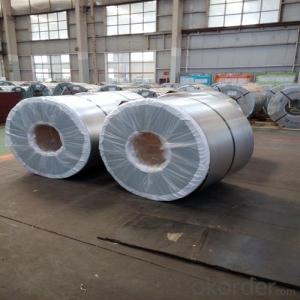

3.Prime Quality Tin Free Steel for Twist-off Caps Use Images

4.Prime Quality Tin Free Steel for Twist-off Caps Use Specification

Thickness: 0.135-0.45mm

Width:600-1020mm

Temper: T2-T5

ISO 9001:2008 JIS

Surface: Finish,bright,stone,matte,silver

5.FAQ of Prime Quality Tin Free Steel for Twist-off Caps Use

-What is MOQ?

Our MOQ would be 25 tons.

- Do you only have prime quality TFS ?

We can supply both prime and second quality TFS.

- Q: How is tinplate affected by different types of cosmetics?

- Tinplate can be affected by different types of cosmetics due to their chemical composition. Certain cosmetics, such as those containing acidic or alkaline ingredients, can cause corrosion or discoloration on the tinplate surface. Additionally, prolonged exposure to certain cosmetics, especially those containing solvents or oils, can lead to the degradation of the protective coating on the tinplate, making it more susceptible to rusting. Therefore, it is important to choose cosmetics that are compatible with tinplate packaging to ensure its longevity and integrity.

- Q: How does tinplate contribute to the overall sustainability of packaging?

- Tinplate contributes to the overall sustainability of packaging in several ways. Firstly, tinplate is a recyclable material, meaning it can be reused indefinitely without losing its quality or properties. This reduces the need for constantly producing new packaging materials and helps to conserve natural resources. Additionally, tinplate is a durable material that provides excellent protection for the packaged goods, reducing the risk of damage or spoilage. This leads to less food waste and a more efficient use of resources. Moreover, tinplate has a long shelf-life, ensuring the preservation of the packaged products for extended periods without the need for additional packaging or preservatives. Overall, the use of tinplate in packaging promotes sustainability by reducing waste, conserving resources, and preserving the quality and safety of the packaged goods.

- Q: How is tinplate priced?

- Tinplate is typically priced based on various factors such as the current market demand and supply dynamics, raw material costs, production expenses, and market competition. Additionally, other factors like quality, specifications, and coating type may also influence the pricing of tinplate.

- Q: What are the cleaning agents suitable for tinplate?

- Some cleaning agents suitable for tinplate include mild dish soap, vinegar, baking soda, and commercial metal cleaners.

- Q: What are the food safety regulations for tinplate packaging?

- The food safety regulations for tinplate packaging include ensuring that the tinplate used is food-grade and does not contain any toxic substances that could contaminate the food. The packaging should also be properly sterilized to prevent any bacterial growth. Additionally, tinplate packaging should be designed to prevent any leakage or contamination during storage and transportation.

- Q: How does tinplate contribute to the overall sustainability of the supply chain?

- Tinplate contributes to the overall sustainability of the supply chain in several ways. Firstly, it is a highly recyclable material, which means that it can be reused multiple times without compromising its quality. This reduces the need for virgin materials and minimizes waste generation. Secondly, tinplate has excellent barrier properties, protecting the contents of the packaging from external factors such as light, moisture, and oxygen, thus reducing food waste and extending shelf life. Additionally, tinplate is lightweight yet sturdy, enabling efficient transportation and reducing carbon emissions during shipping. Overall, tinplate's recyclability, protective properties, and transportation efficiency make it a sustainable choice in the supply chain.

- Q: Can tinplate be used for packaging personal care products?

- Yes, tinplate can be used for packaging personal care products. Tinplate is a commonly used material for packaging due to its durability, corrosion resistance, and ability to preserve the quality and shelf life of the products. It is also a sustainable option as it is recyclable and can be reused.

- Q: Can tinplate be painted?

- Yes, tinplate can be painted. Tinplate is commonly used in the production of cans and other packaging materials, and it is suitable for various coating processes, including painting. The surface of tinplate can be treated and primed before applying paint, ensuring good adhesion and durability of the painted finish.

- Q: What are the different ways to recycle tinplate packaging?

- There are several different ways to recycle tinplate packaging. One common method is to sort and separate the tinplate from other materials, such as paper or plastic, at recycling facilities. This allows the tinplate to be melted down and used to create new products. Another option is to reuse tinplate packaging for storage purposes, such as using empty tin cans to organize small items. Additionally, some people repurpose tinplate packaging for crafts or DIY projects, giving it a new life and purpose.

- Q: How is tinplate affected by exposure to UV light?

- Tinplate is generally not affected by exposure to UV light as it is a highly durable and corrosion-resistant material. However, prolonged exposure to intense UV radiation may cause minor color fading or surface discoloration over an extended period of time.

Send your message to us

Prime Quality Tin Free Steel for Twist-off Caps Use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 25000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords