Three And Five Layers Co-Extrusion Film Blowing Machine Film Blowing Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | nude packing or wooden case packing as your request |

| Delivery Detail: | 30 days after receipt 30%T/T as deposite |

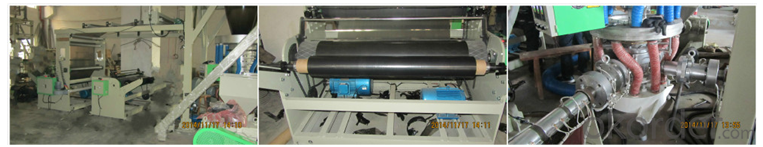

Three to five layers co-extrusion film blowing machine set (IBC), extruder, blowing machine

This machine set is to satisfy the customer’s requirements of high quality, high output film blowing equipment.

It adopts the extruder with force feeding function, precision type ceramic heater, precision type double vents air ring, horizontal type rotary traction system, fully automatic surface friction type double cut double winders, computer concentrate control system.

Advanced technique and equipments, compare with kindred equipment, it has the advantages such as more compact structure, high output, better produce quality, less energy consume, easier operation.

It can be widely used into various kind of high transparence packing film manufacture and create the considerable economic benefit for you.

Fully automatic double cut double winders

Optional parts:

Auto loaderX3pcs

Chiller

Corona

Full automatic winder

Embossing roller

collecting material drop

Technical data:

Model | MD-3L50 | MD-3L55 | MD-3L65 |

Suitable Material | LDPE LLDPE EVA HDPE | ||

Max Film Width(mm) | 1200 | 1500 | 2000 |

Film Thickness(mm) | LD:0.015-0.15 | ||

Max Extrusion Output LD | 140kg/hr | 200kg/hr | 280kg/hr |

Extrusion unit | |||

Gear Box | 146/173/146 | 173/200/173 | 200×3 |

Screw Diameter(mm) | φ50/55/50 | φ55/65/55 | φ65/65/65 |

Screw L/D Ratio | 28:1 | ||

Screw’s Material | 38 CRMOALA | ||

Barrel’s Material | 38 CRMOALA | ||

Barrel’s Cooling Fan | 370W×2×3 | 370W×2×3 | 370×3×3 |

Thermo Control (zone) | 3×3 | 3×3 | 4×3 |

Driving Motor (kw) | 15/22/15 | 22/30/22 | 30/30/30 |

Extrusion Die | |||

Die Size (mm) | LD:φ250/300 | LD:φ350/400 | LD:φ500 |

Rotary Die Head (mm) | 360°Continue Rotary | ||

Screen Changer | Manual Mechanics Screen Changer | ||

Thermo Control (zone) | 3 | 4 | 4 |

Air Ring | 1 PCS | ||

Cooling Blower (kw) | 5.5 | 7.5 | 11 |

Take-UP Unit | |||

Roller Width (mm) | φ165×1300 | φ165×1600 | φ190×2100 |

Take-UP Motor (kw) | 1.5 | 1.5 | 2.2 |

Take-UP Speed(M/min) | 5-60 | 5-60 | 5-60 |

Winding Unit | |||

Type OF Winder | Surface Friction Double Winder | ||

Roller Width (mm) | 1300 | 1600 | 2100 |

Winding Motor | 16N.M | 1.5kw | 1.5kw |

Winding Speed(M/min) | 5-60 | 5-60 | 5-60 |

Voltage | 380V, 50HZ, 3PHASE | ||

Cover Dimensions (m) | 6.8×2.6×6.5 | 7.5×3.2×7.5 | 9×4.2×9 |

Three to five layers co-extrusion film blowing machine set (IBC), extruder, blowing machine

Machine at factory,double winder,simple type

Our other hot-sale machine(click the picture to know more information)

Company show

- Q: What is the working vacuum in the oil filter?

- Therefore, the so-called "working vacuum" is the vacuum filter oil function, the completion of gas-liquid separation and oil-water separation function vacuum control range.

- Q: Comment: what's the difference between a vacuum oil filter and a centrifugal oil filter?

- 3, focus on different application fields: vacuum filter oil machine with high precision, can filter the water and impurities, but also can remove gas, acid value reduction, therefore in the filtration of various industrial oil (lubricating oil, hydraulic oil, turbine oil, turbine oil, anti oil, transformer oil) and other areas of application is very wide. Centrifugal oil filter can filter water and filter impurities, but the speed and physical ability by centrifuge limit, filtering precision and filtering ability cannot and vacuum oil filter, therefore centrifugal mainly applied in food more oil fields, oil industry only in the filtering requirements without high requirement will be used centrifugal oil filter.

- Q: Pneumatic oil filter is slow, isn't it too low?

- Strong magnetic mainly adsorption iron elements, other impurities mainly through the filter block, once the interception of impurities is too much, blocking the filter, on the one hand

- Q: How to choose insulating oil vacuum filter

- 2. Large area flashing technology of branched nozzle, unique patent separation system, free maintenance. High vacuum rapid and efficient removal of volatile oils, such as water, gas and hydrogen in insulating oil. Increase the compressive strength and the quality of the oil.

- Q: What is the selection of the oil filter for the turbine?

- Steam turbines are generally used by power plants, so the amount of steam turbine oil is large and the demand for filtration is relatively strong. As for the selection of the flow rate of the turbine oil filter, this can be chosen according to the quantity of oil used in your factory and how many tons are required to be filtered every day

- Q: What happens when the oil heater is fired and the heater is tripped?

- Oil filter is mainly used to improve the cleanliness of machinery and electrical oil, so as to give full play to the best performance and extend the service life of equipment.

- Q: What is the accuracy of 300*300 oil filter paper for LY-100 plate and frame pressure oil filters?

- The filtering accuracy of filter paper is only concerned with the material of filter paper, the production process and the power of fiber weaving of filter paper.

- Q: Imported vacuum purifier, oil filter, why Parker is known as the world's first?

- From the energy consumption, from the service, from customer satisfaction, a relatively clear, and also used to say?!

- Q: I am pressed sunflower oil, vacuum phase electric heating oil filter, oil filter to the end why there is a place

- In short, there is foam very normal, static for a while, there will be No.If the cooking oil is heated after foam, that phospholipids in oil more, you need to dephosphorization.

- Q: Fig. 1 electrical control diagram of lubricating oil vacuum oil filter lv_80

- Besides the general bought oil filter, as long as the regular manufacturers will have the instructions, the above detailed parameters of oil filter, and the electrical principle diagram and electrical control chart, do you buy the oil filter machine instructions are not even,. If so, either you choose to return it, or you call the person who sold it to you, and let them come home to deal with the problem, which is the minimum after-sales service.

Send your message to us

Three And Five Layers Co-Extrusion Film Blowing Machine Film Blowing Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords