Thread protection sleeve, drill rod protection thread

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

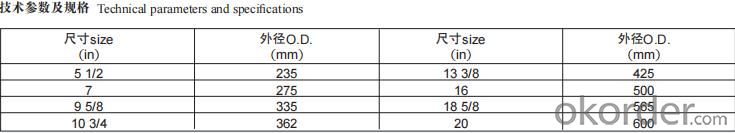

Specification

Thread protection sleeve, drill rod protection thread

Quick installation thread protector is a tool used to protect the threads of casing during drilling or mining operations. Its main function is to prevent thread damage during casing operations.

The main advantages of quick installation wire protection include fast loading and unloading, simple structure, convenient use, safety and reliability, and can reduce labor intensity and improve labor efficiency.

1.Quick loading and unloading: Through special structural design, the installation and disassembly process of the wire protector is quickly completed, improving work efficiency.

2.Simple structure: The overall structural design is reasonable, the functions of each component are clear, and it is easy to operate and maintain.

3.Easy to use: The operation process does not require complex tools or skills, even untrained personnel can easily use them.

4.Safe and reliable: Made of high-strength materials to ensure safety and stability during use.

5.Reduce labor intensity: By optimizing the design, the physical exertion during the operation process has been reduced, protecting the health of the operator.

- Q: What is the tensile strength of silicone rubber?

- The tensile strength range of silicone rubber is 3.4-14.7Mpa, depending on the formula!

- Q: How can I remove the rubber flavor on rubber products? It smells terrible

- Different types of rubber deodorant by different chemical AO and effect, which can effectively remove all kinds of rubber, including reclaimed rubber, flame retardant rubber smell in the processing and use of rubber products, improve the level of environmental protection, applicable to all kinds of rubber molding process. The utility model has the advantages of low use, high efficiency, safety and innocuity

- Q: How do rubber undergo vulcanization?

- Heat vulcanization can be divided into three methods: direct vulcanization, indirect vulcanization and mixed gas vulcanization. Direct vulcanization; vulcanizing in hot water or steam medium. Indirect vulcanization, vulcanization in hot air. Third, gas vulcanization, first vulcanization with air, and then direct steam vulcanization.

- Q: How to enhance the performance of water resistant silicone rubber products

- Steam can also reduce the performance of silicone rubber / silicone products, essentially the fracture of the backbone. The hydrolysis fracture reaction becomes apparent due to the increase of temperature and the presence of ionic reagents.

- Q: High strength rubber repairing agent

- Of course, the rubber repair agent is used in the construction of the drum and plastic interface, and there should be some other applications, so that we can know more about it.

- Q: How is rubber made? What kind of equipment do you need? How much is it?

- Method for making rubber:A latex used in rubber plants, such as rubber trees, rubber, and grasses, for making flexible, insulating, impermeable, and air filled materials. High elastic polymer compound. It is divided into two kinds: natural rubber and synthetic rubber. Natural rubber is made from rubber, tree, rubber, grass and other plants. The synthetic rubber is obtained by polymerization of various monomers. Rubber products are widely used in industry or in all fields of life.

- Q: Comparison of physical properties of HNBR rubber material with other rubber materials

- Hydrogenated nitrile rubber, referred to as "HNBR" or "H-NBR". It is a new variety of nitrile rubber (NBR).

- Q: How can the rubber shoes be dyed?

- The sole of balata bottom shoe according to the specific distinction of material, can be divided into natural balata bottom shoe, wear-resisting balata bottom shoe, balata bottom shoe, mix balata bottom shoe, EVA balata bottom shoe. The sole uses the chemical synthesis material to be many, generally selects the cold resistant material in winter, in summer must choose the anti - high temperature material.

- Q: What are the causes of chapped rubber products?

- Measures to prevent aging:From the point of view of aging, one of the main reasons is the polymer structure itself. Therefore, it is important to improve the structure of polymers to improve their aging ability. For example, in rubber vulcanization, there are still unsaturated double bonds, and rubber products in use and it is difficult to avoid the erosion of sunlight, oxygen, ozone, so people on the synthesis of new varieties, to avoid or reduce the polymer chain of rubber double bonds, such as ethylene and propylene two monomer by copolymerization made two yuan B two rubber, different from other synthetic rubber is one of the major characteristics in the structure of the backbone is not completely saturated with double bond, making it the most ozone resistance, chemical resistance, high temperature resistant rubber aging; there is a kind of antioxidant, such as adding oxygen or ozone to prevent aging caused by antioxidants. Add UV stabilizers, heat stabilizers, preservatives and other unfavorable factors, and caused by aging

- Q: What are the disadvantages of a rubber roof?

- The rubber roof house is very hot in summer because the rubber is airtight and airtight.

Send your message to us

Thread protection sleeve, drill rod protection thread

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords