Thermal Insulation Ceramic Fiber Module for Fireplace

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

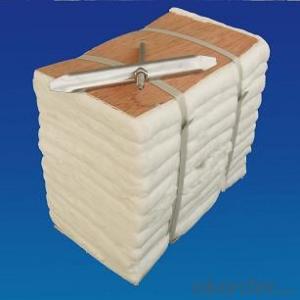

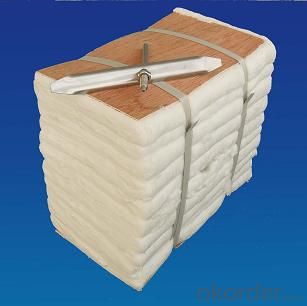

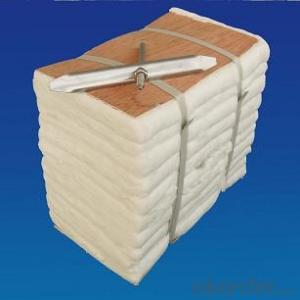

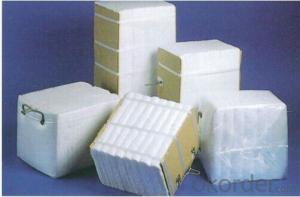

Thermal Insulation Ceramic Fiber Module for Fireplaces

Product Description:

Ceramic fiber modules, also called aluminum silicate fiber modules, are a ceramic raw material coal gangue. After calcining, grinding, and after being melted into a liquid, the ceramic fiber cotton is further processed into ceramic fiber modules. On the basis of the characteristics of ceramic materials, ceramic fiber modules are fireproof, preserve heat, insulate, absorb sound, save energy, and are widely used in petroleum, chemical and metallurgical machinery, as well as in building materials and other industries.

Product Features:

• Good High temperature stability, low thermal conductivity

• Good thermal shock resistance, corrosion resistance

• Easy to be machined and cut

• Good resistance to fire and high temperature gases

• Easy to install

Product Applications:

Ceramic fiber modules can directly fixed on the industrial kiln furnace shell steel anchor nails, and offer fireproofing and heat insulation, improving the integrity of kiln refractory and heat insulation. This promotes the progress of kiln lining technology classification temperatures from 1050-1400℃.

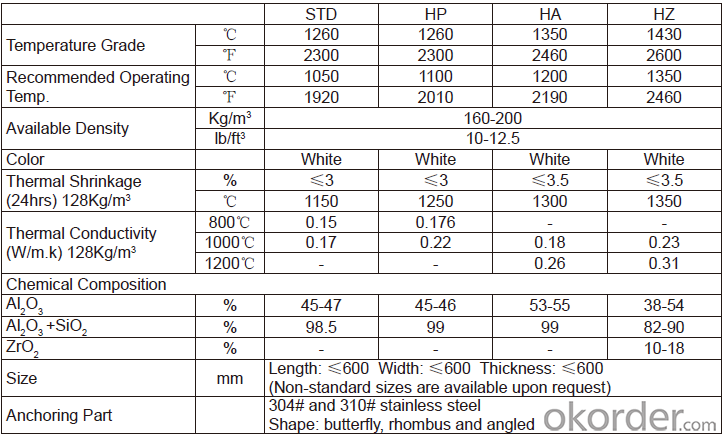

Product Specifications:

Product Images:

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What other products does OKorder offer?

A3: We offer a full range of refractory bricks, mortar, cement, ceramic fiber products, and more.

Q4: Where are Ceramic Fiber products used?

A4: Ceramic fiber products have many advantages, including: high temperature stability, lightweight, superior insulation, and ease of application. Fiber products are available in a variety of product forms to solve a range of thermal management application problems across various industries. The main industrial market segments that use ceramic fiber and soluble fiber products are the aluminum, iron, steel, heat treatment, power, incineration, boilers, and glass industries.

Q5: What kind of Ceramic Fiber should I use?

A5: When selecting the fiber type for a particular application, it is important to consider all factors. If the fiber/fabric will not have to support a load at temperature, the lower-cost industrial grade fibers may be appropriate. However, if the fiber will be load bearing at temperature as in ceramic matrix composites, then one of the composite grade fibers would be a better choice. Of course there may be other factors, such as corrosion, chemical resistance, or atmospheric conditions that may require trade-off in the selection process.

Q6: What`s the lead time for my order?

A6: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks, 10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q7: Can you offer Door-to-Door delivery?

A7: Yes, but only for some countries such as U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q8: What is the minimum quantity?

A8: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

- Q: Can ceramic fibers be spun? Hope experts answer, if you are the one!

- It should be spun from cotton, spun into spun yarn, and then joined with wire or glass fiber, and then twisted into threads to make cloth or rope

- Q: Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Ceramic fiber board is of high quality ceramic fiber cotton with low slag ball content as raw material, using specific pulp and mixing equipment, ensure the cutting length and the concentration uniformity of cotton fiber, using international advanced vacuum molding technology and international advanced processing technology, the product not only has excellent mechanical strength and precise geometry the size, and maintains the excellent properties of fibrous insulation materials, can be substituted for calcium silicate board also requires tough, self-supporting and refractory insulation field.

- Q: Ceramic fiber module or refractory brick for hot galvanizing furnace body insulation? Who gave me an analysis?

- The arrangement mode of the ceramic fiber module adopts "soldier row type" - along the module compression size. Fiber module arrangement using ceramic fiber blanket folded thickness after 20mm compression, and the use of "U" type nail to keep the 500~700mm distance to the fiber module fixed to insert compensation fiber expansion surface may produce contraction, the structure can avoid the "parquet" arrangement, fiber module for the corner site the expansion caused by uneven phenomenon, "playboy" has the best effect of adiabatic. When the back lining of the furnace top is installed, the quick card matching module is used for temporary fixing with bolts.

- Q: How to install refractory fiber?

- Good chemical stability; good thermal stability; excellent elasticity, ceramic fiber module is pre pressed state, in lining up after the expansion of ceramic fiber module to enable seamless lining, and can compensate for fiber lining contraction, in order to improve the insulation performance of fiber lining, the overall performance is good; excellent thermal stability and thermal shock resistance the ceramic fiber module; quick installation, and anchors set in the wall lining noodles, can reduce the anchor material requirements.

- Q: What about the composite reflecting insulation board and ceramic fiber?

- The maximum temperature of ceramic fiber heat insulation material can be up to 1400 degrees. Although the highest use temperature of ceramic fiber is higher than that of Tianjin solid composite reflecting insulation board, the heat insulation effect is far worse.

- Q: What is the refractory temperature of the ceramic fiber cloth?

- Nichrome wire reinforced stainless steel wire reinforced, glass fiber, ceramic fiber coating, ceramic fiber cloth with slag, sintered ceramic fiber cloth, ceramic fiber cloth) fumigation characteristics of ceramic fiber cloth: high temperature resistance, low thermal conductivity, low heat capacity, thermal shock;

Send your message to us

Thermal Insulation Ceramic Fiber Module for Fireplace

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords