Ceramic Fiber Module Refractory or Insulation Heat Lining Industrial Furnace

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

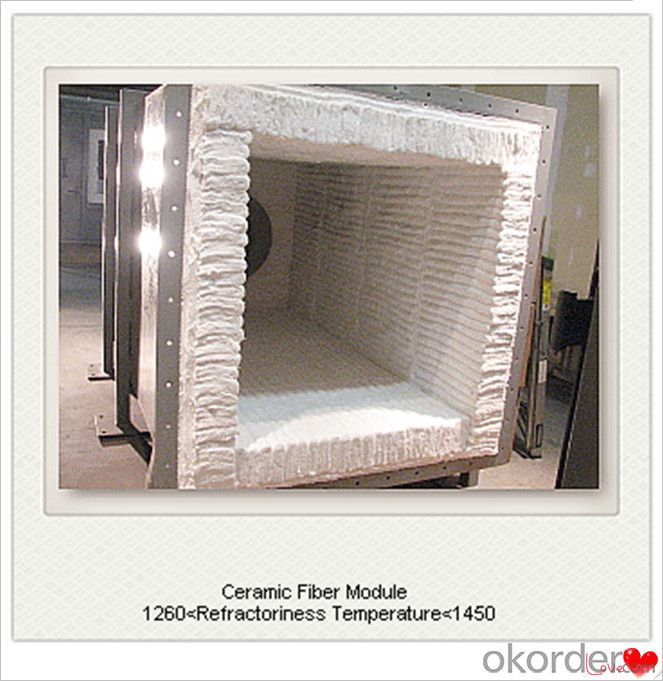

Industrial Furnace Heat Lining Ceramic Fiber Module Refractory / Insulation

Product Description:

Ceramic fiber is made from high quality clay, high purity alumina and silica oxides by spun or blown process. Ceramic fiber has a range of products: ordinary type, standard form, high-purity type, high-alumina type and containing zirconium type. Different types of products use different materials. The performance of ceramic fiber is also different, and they are suitable for different working temperatures.

Ceramic fiber can be used after optional cutting. When storing ceramic fiber, pay attention to moisture. The high-alumina type and containing zirconium type products can be directly used as furnace linings.

Product Features:

• Low thermal conductivity

• High tensile strength

• Resilient to thermal shock

• Corrosion resistance

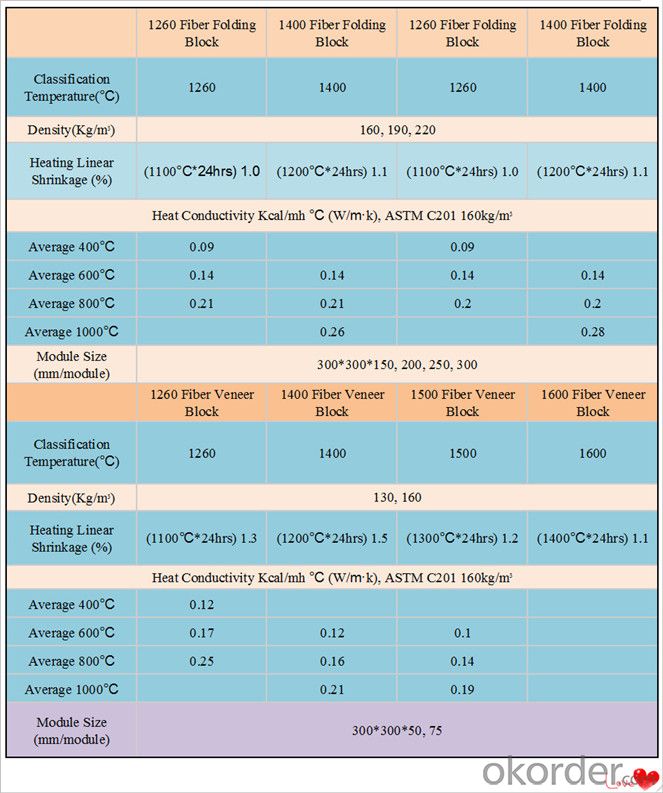

Product Specifications:

Al Content (%): 32-55

Type: 1260℃ STD/HP, 1350℃ HA, 1430℃ HZ

Density: 64-160kg/m³

Size: 12.5×610×14400mm, 25×610×7200mm, 50×610×3600mm

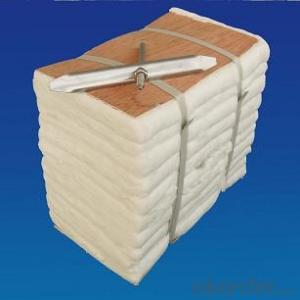

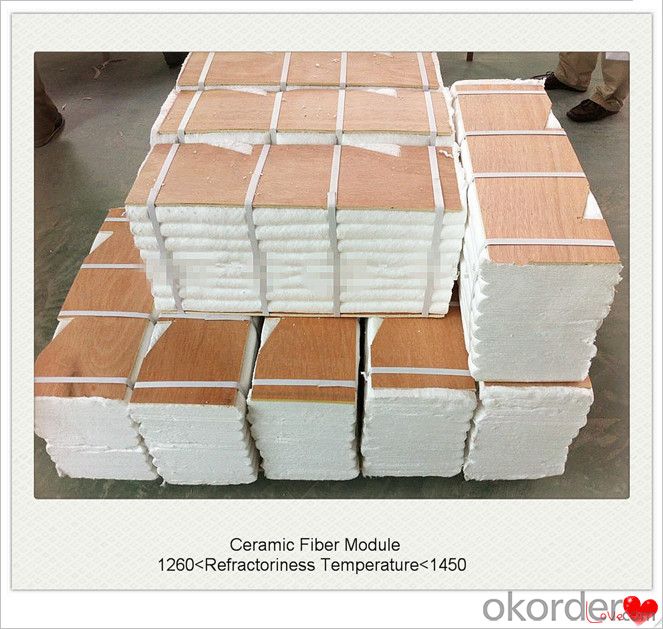

Product Packing:

Plastic bag in a carton box

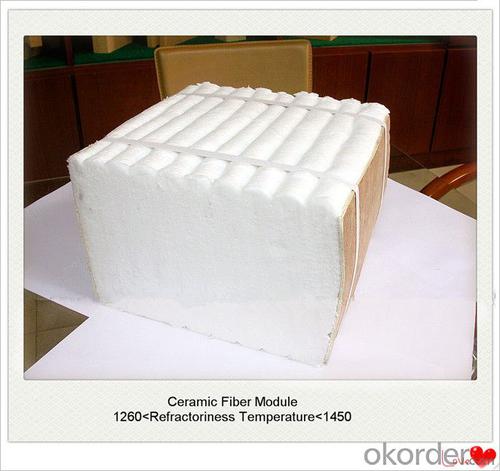

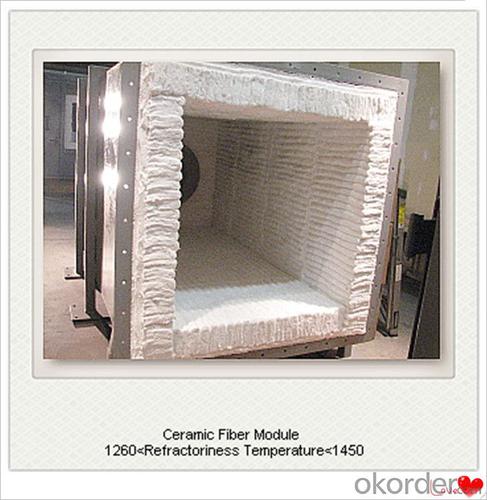

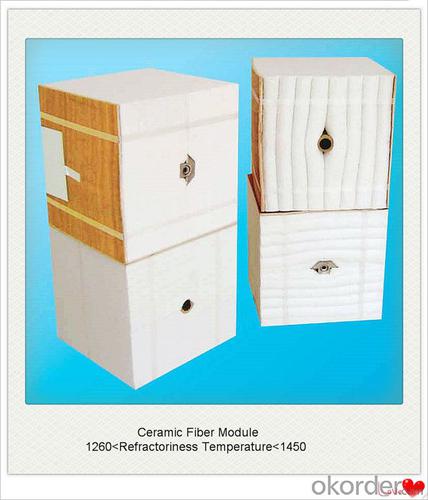

Product Images:

Techincal Data for Ceramic Fiber Module

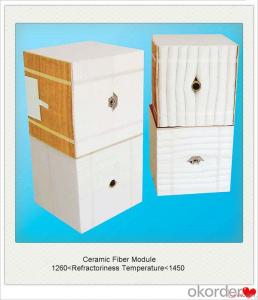

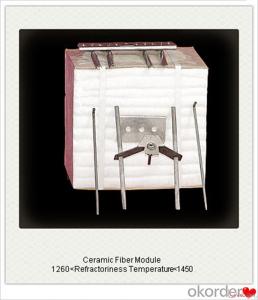

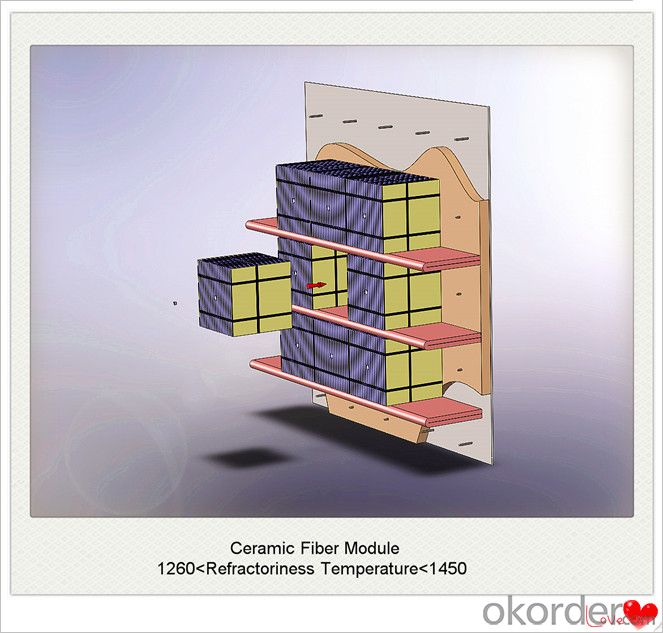

Images for Ceramic Fiber Module

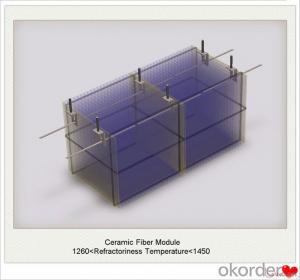

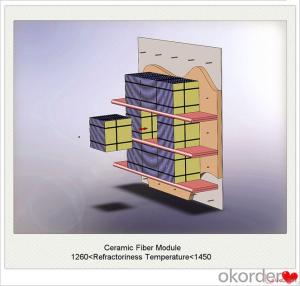

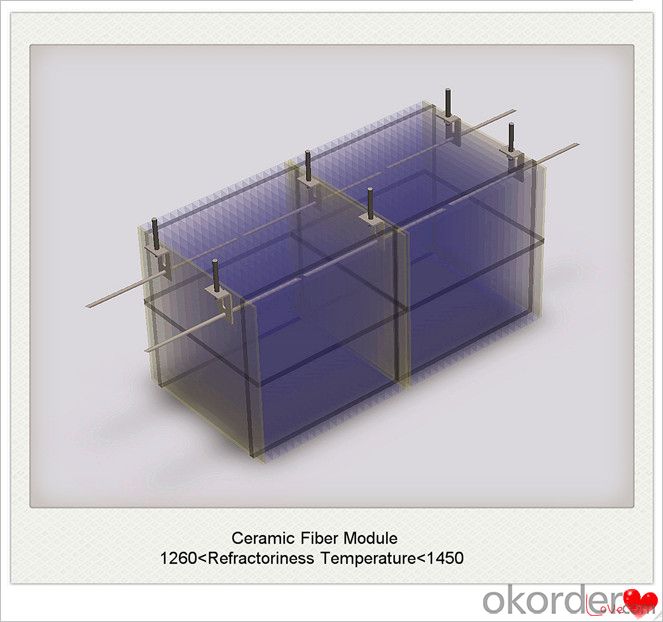

3D Drawinng for Anchorage of Ceramic Fiber Module

Packaging and Delivery for Ceramic Fiber Module

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What other products does OKorder offer?

A3: We offer a full range of refractory bricks, mortar, cement, ceramic fiber products, and more.

Q4: Where are Ceramic Fiber products used?

A4: Ceramic fiber products have many advantages, including: high temperature stability, lightweight, superior insulation, and ease of application. Fiber products are available in a variety of product forms to solve a range of thermal management application problems across various industries. The main industrial market segments that use ceramic fiber and soluble fiber products are the aluminum, iron, steel, heat treatment, power, incineration, boilers, and glass industries.

Q5: What kind of Ceramic Fiber should I use?

A5: When selecting the fiber type for a particular application, it is important to consider all factors. If the fiber/fabric will not have to support a load at temperature, the lower-cost industrial grade fibers may be appropriate. However, if the fiber will be load bearing at temperature as in ceramic matrix composites, then one of the composite grade fibers would be a better choice. Of course there may be other factors, such as corrosion, chemical resistance, or atmospheric conditions that may require trade-off in the selection process.

- Q: Can ceramic fibers be spun? Hope experts answer, if you are the one!

- Ceramic fiber can be spun, but certain auxiliary materials must be added. The ceramic fiber is soft, and the resistance and non - fiber of the ceramic fiber must be guaranteed.

- Q: Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Ceramic fiber board is of high quality ceramic fiber cotton with low slag ball content as raw material, using specific pulp and mixing equipment, ensure the cutting length and the concentration uniformity of cotton fiber, using international advanced vacuum molding technology and international advanced processing technology, the product not only has excellent mechanical strength and precise geometry the size, and maintains the excellent properties of fibrous insulation materials, can be substituted for calcium silicate board also requires tough, self-supporting and refractory insulation field.

- Q: Ceramic fiber module or refractory brick for hot galvanizing furnace body insulation? Who gave me an analysis?

- After 2013, the hot dip galvanizing furnace is usually made of ceramic fiber modules for insulation, as follows:The appearance of new thermal insulation material breaks the inherent heat loss barrier in our country. The new type of thermal insulation material is mainly made of ceramic fiber and heat insulation cotton. It is combined with bolt, nut, carpet blanket, module and compensation blanket to achieve high heat preservation.

- Q: How to install refractory fiber?

- Dry plate is used spray adhesive, mechanical compression molding, low density, has good flexibility and flexibility, generally used for insulation seal. Wet washing mold, vacuum forming board of high density, good hardness, can be processed mechanically, generally used for fire-resistant insulation.

- Q: What about the composite reflecting insulation board and ceramic fiber?

- Heat insulation material with low thermal conductivity of ceramic fiber products, but this insulation material is soft material, some aspects of the use of defects. In contrast, Tianjin solid microporous nano insulation board has lower thermal conductivity.

- Q: What is the refractory temperature of the ceramic fiber cloth?

- Non-toxic, harmless, no adverse effects on the environment; the scope of application of ceramic fiber cloth: all kinds of high temperature furnace, thermal insulation pipes and containers; door, valve, flange sealing, fire door, fire shutter door curtain, high temperature sensitive materials; engine and instrument cable insulation, fireproof coating material, fireproof material; thermal insulation cover with cloth, high temperature expansion joint filler, flue lining; high temperature resistant safety products, fire service, high temperature filtration, sound and other fields instead of asbestos

Send your message to us

Ceramic Fiber Module Refractory or Insulation Heat Lining Industrial Furnace

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords