Textured Aluminum Coil Stock for Mill Finish Aluminum Roofing Coil for Channel Letter

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Auminum Roofing Coil for Channel Letter

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3A21 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum or paper |

7) Coil Inner diameter | 75mm, 150mm, 200mm, 300mm, 405mm, 505mm or as required |

8) Protective film can be added

2. Application of Mill Finish Auminum Roofing Coil for Channel Letter

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Auminum Roofing Coil for Channel Letter

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

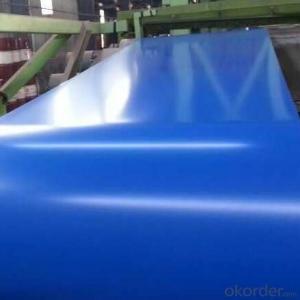

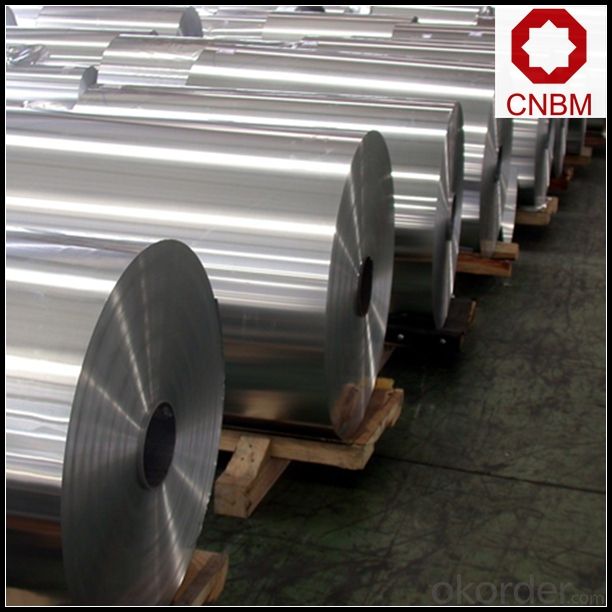

5. Image of Mill Finish Auminum Roofing Coil for Channel Letter

6. Package and shipping of Mill Finish Auminum Roofing Coil for Channel Letter

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are aluminum coils suitable for corrosion-resistant applications?

- Yes, aluminum coils are suitable for corrosion-resistant applications. Aluminum has natural corrosion-resistant properties as it forms a protective oxide layer when exposed to air, which prevents further corrosion. Additionally, aluminum can be further enhanced with various coatings or treatments to increase its resistance to corrosion, making it a suitable choice for applications where corrosion resistance is required.

- Q: I am looking to bake some Buffalo wings and am wondering if it's alright to bake them in an aluminum pan (disposable or otherwise). I will be brushing/basting the chicken in the sauce not 'drowning' the chicken in it. I have heard that acidic sauces like Tomato sauce (less acidic than wing sauce) should not be cooked in aluminum (stovetop pans bakeware) because of some chemical interaction, but I've seen those big foil pans full of pasta spaghetti sauce at wedding, etc. Is the whole acid/aluminum thing true or an old cooking myth?

- I think it should be fine. Ive never heard that before. However aluminum conducts heat differently so it may change the end result. You might want to consider deep frying your wings. At the very least par boil them first so that you can get them crispy

- Q: Are aluminum coils suitable for coil coating applications?

- Yes, aluminum coils are suitable for coil coating applications. Aluminum is widely used in coil coating due to its excellent corrosion resistance, lightweight nature, and high strength-to-weight ratio. It is also highly malleable, allowing for easy shaping and forming during the coil coating process. Additionally, aluminum coils can be coated with various types of paints and coatings, providing a wide range of color and finish options. Overall, aluminum coils are a popular choice for coil coating applications due to their versatility, durability, and aesthetic appeal.

- Q: How are aluminum coils tested for surface hardness?

- Aluminum coils are tested for surface hardness through a variety of methods to ensure their quality and suitability for various applications. One common method used is the Rockwell hardness test. In the Rockwell hardness test, a diamond or hardened steel ball is pressed into the surface of the aluminum coil using a specified amount of force. The depth of the indentation made by the ball is measured, and a hardness value is determined based on the difference in depth before and after applying the force. This value is then compared to a hardness scale to determine the surface hardness of the aluminum coil. Another method used is the Brinell hardness test. In this test, a hardened steel ball is pressed into the surface of the aluminum coil using a specified force. The diameter of the resulting indentation is measured, and a hardness value is calculated based on the applied force and the size of the indentation. This value is then compared to a hardness scale to determine the surface hardness of the aluminum coil. Both the Rockwell and Brinell hardness tests are non-destructive and provide accurate measures of the surface hardness of aluminum coils. These tests help manufacturers and customers ensure that the coils meet the required hardness specifications for their intended applications, such as in the automotive or construction industries. By testing for surface hardness, potential issues like brittleness or inadequate strength can be identified and addressed before the aluminum coils are used in the production process.

- Q: What is the primary function or use of a spring steel wire coil?

- <p>A spring steel wire coil is primarily used for its high elasticity and strength. It is designed to return to its original shape after being deformed, which makes it ideal for applications requiring resilience and durability. Common uses include the manufacturing of various types of springs, such as compression springs, torsion springs, and extension springs, found in automotive suspensions, mechanical devices, and industrial equipment. The coil's properties also make it suitable for applications in furniture, electronics, and other industries where a reliable and consistent force is needed.</p>

- Q: Can aluminum coils be customized to specific requirements?

- Indeed, specific requirements can be accommodated through customization of aluminum coils. The versatility of aluminum coils allows for a broad range of specifications and applications to be met. Customization options encompass alloy selection, coil thickness, width, and length, as well as diverse surface treatments like coatings, finishes, and embossing. Furthermore, mechanical properties such as strength, flexibility, and corrosion resistance can be tailored to individual needs. To achieve desired outcomes, close collaboration with manufacturers or suppliers possessing the necessary expertise and facilities is necessary. Whether for the aerospace industry, automotive sector, construction projects, or any other usage, aluminum coils can be tailor-made to fulfill specific requirements and deliver optimal performance.

- Q: Can aluminum coils be embossed or textured?

- Aluminum coils possess the capability to undergo embossing or texturing, thereby enabling the creation of patterns or designs on their surface. This can be achieved through mechanical or chemical processes. The resulting embossed or textured surface not only enhances the visual appeal but also improves the functionality of the aluminum coil, by augmenting its grip or minimizing glare. Consequently, these aluminum coils, with their embossed or textured features, have found widespread utilization across industries like construction, automotive, and packaging.

- Q: Classification of aluminium rolls for aluminium rolls

- To spare, so in order to cope with the development of science and technology, in order to contain other aluminum alloy elements, the International Federation of special aluminum strip showed that 9000 series of alternate series, waiting for a new product to fill the gaps of the 9000 series.

- Q: Are aluminum coils suitable for high-pressure applications?

- No, aluminum coils are not suitable for high-pressure applications.

- Q: What benefits can utilizing aluminum coil bring to the construction industry?

- <p>Aluminum coil offers several advantages in construction, including its lightweight nature which reduces structural load and facilitates easier handling and installation. It is highly resistant to corrosion, ensuring longevity and low maintenance costs. The material is also known for its excellent thermal conductivity, making it suitable for energy-efficient applications. Additionally, aluminum coil is recyclable, contributing to sustainability and reducing environmental impact. Its versatility allows for various applications, from roofing and siding to structural components, enhancing aesthetic appeal and functionality.</p>

Send your message to us

Textured Aluminum Coil Stock for Mill Finish Aluminum Roofing Coil for Channel Letter

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords