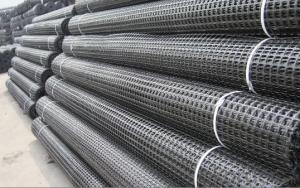

Tenax High Strength Biaxial Geogrids - Manufactured PP

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of PP/HDPE Biaxial Geogrid:

Uniaxial geogrid, made of high molecular polymer, is extruded into sheet and then punched into regular mesh pattern, and finally stretched in the longitudinal direction.

Features of PP/HDPE Biaxial Geogrid:

With high tensile strength and tensile modulus

Application of PP/HDPE Biaxial Geogrid:

Mainly applied in highway, railway, slope protecting projects, retaining wall, dam etc.

1)strengthen land loading capacity and extend its service life.

2) convenient to construct ; reducing area , project cost and maintenance cost.

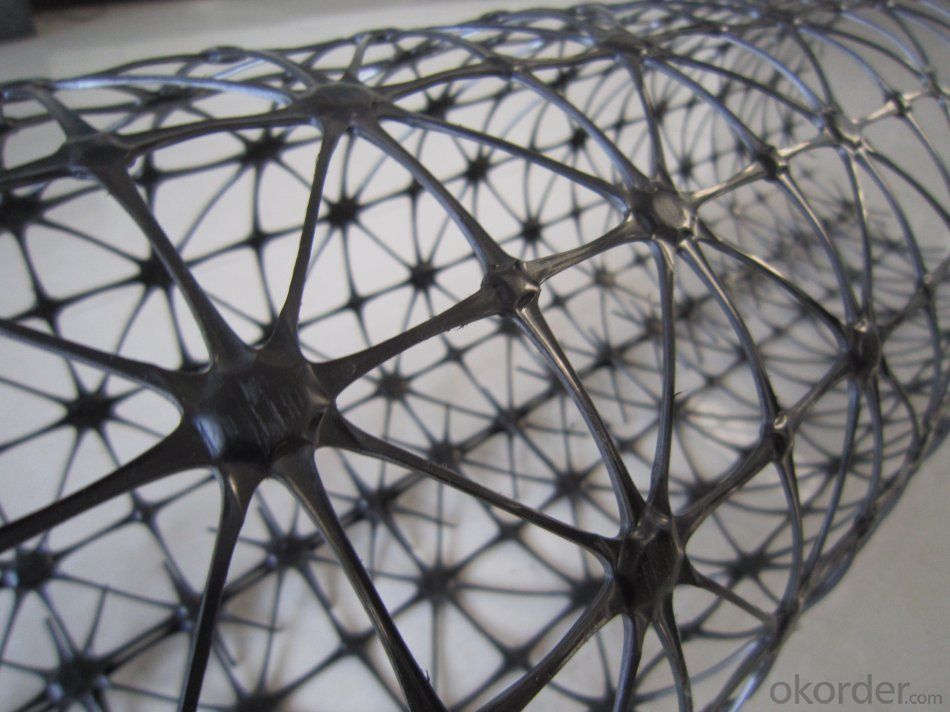

Features of PP Biaxial Geogrid:

1. With high tensile strength in longitudinal and transversedirections

2.This structure can provide an chain system of more effective force bearing and spreading for the soil.

Application of PP Biaxial Geogrid:

Mainly applied in highway, railway, slope protecting projects etc.

1)strengthen land loading capacity and extend its service life.

2) convenient to construct ; reducing project cost and maintenance cost.

Features of Polyester Geogrid:

1) High tensile strength

2) High tear-resistant

3) Strong combination with gravel and soil

Application of Polyester Geogrid:

It mainly applied in strengthening soft ground of rail and road.

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: Glass fiber grille is not geogrid

- Yes, one of the three categories of geogrid. Fiberglass grille is another kind of glass fiber geogrid.

- Q: What is the effect of installation damage on geogrid performance in long-term applications?

- The effect of installation damage on geogrid performance in long-term applications can be detrimental. Installation damage, such as punctures, tears, or stretching, can weaken the geogrid's structural integrity and reduce its ability to provide long-term reinforcement. This can lead to decreased stability, reduced load-bearing capacity, and potential failure of the geogrid system over time. Therefore, it is crucial to handle and install geogrids carefully to minimize any damage and ensure optimal performance in long-term applications.

- Q: Do geogrids enhance the load-bearing capacity of soil?

- Yes, geogrids can enhance the load-bearing capacity of soil. Geogrids are typically made of high-strength materials and are used to reinforce soil by providing additional tensile strength. When placed within the soil, geogrids distribute the load more evenly, reducing the potential for soil failure and increasing the load-bearing capacity of the soil.

- Q: Are geogrids suitable for use in mine tailings containment?

- Yes, geogrids are suitable for use in mine tailings containment. Geogrids are high-strength, durable materials that can effectively stabilize and reinforce soil or rock structures. They can be used to create stable walls, slopes, or liners in tailings containment areas, helping to prevent erosion, control flow, and enhance the overall stability of the containment system.

- Q: Can geogrids be used in soil erosion control for agriculture?

- Yes, geogrids can be used in soil erosion control for agriculture. Geogrids are commonly used in agricultural applications to stabilize the soil, prevent erosion, and improve water drainage. They provide structural support to the soil, reducing the risk of erosion caused by wind or water. Additionally, geogrids can enhance the growth of vegetation by holding the soil in place and minimizing the loss of fertile topsoil.

- Q: Can geogrids be used in pipeline trench stabilization applications?

- Yes, geogrids can be used in pipeline trench stabilization applications. Geogrids are commonly used to improve soil reinforcement and provide stability to trenches, including those used for pipelines. They help to distribute loads, prevent soil erosion, and increase the overall strength of the trench.

- Q: What are the advantages of using geogrids in ground improvement for liquefaction mitigation?

- Geogrids offer several advantages in ground improvement for liquefaction mitigation. Firstly, they provide enhanced soil reinforcement, increasing the soil's resistance to liquefaction-induced ground movement. Geogrids also improve the overall stability of the ground by distributing loads more evenly, reducing the risk of differential settlement. Additionally, geogrids can help to increase the bearing capacity of the soil, allowing it to support heavier structures. Moreover, they provide long-term durability and resistance to environmental factors, ensuring their effectiveness over time. Overall, geogrids are a cost-effective and efficient solution for mitigating liquefaction hazards and improving the performance of the ground.

- Q: How many Chinese geogrid manufacturers? How many famous

- Manufacturers have more than N, there is no specific how much to say

- Q: Can geogrids be used in soil reinforcement for load-bearing platforms?

- Yes, geogrids can be effectively used in soil reinforcement for load-bearing platforms. Geogrids are engineered materials that provide soil stabilization and improve the load-bearing capacity of soils. They are typically made of high-strength polymers and have a grid-like structure that interlocks with the soil particles, creating a stable foundation. Geogrids distribute the applied loads more evenly, reducing the potential for soil settlement and enhancing the overall stability of load-bearing platforms.

- Q: Do geogrids provide reinforcement to geosynthetic clay liners in waste containment facilities?

- Yes, geogrids can provide reinforcement to geosynthetic clay liners in waste containment facilities. Geogrids are commonly used in conjunction with geosynthetic clay liners to enhance their tensile strength and prevent their displacement. This reinforcement helps to improve the overall stability and performance of waste containment facilities.

Send your message to us

Tenax High Strength Biaxial Geogrids - Manufactured PP

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords