Tejido Geotextil de Polipropileno No Tejido con Alta Estabilización y Estabilización

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

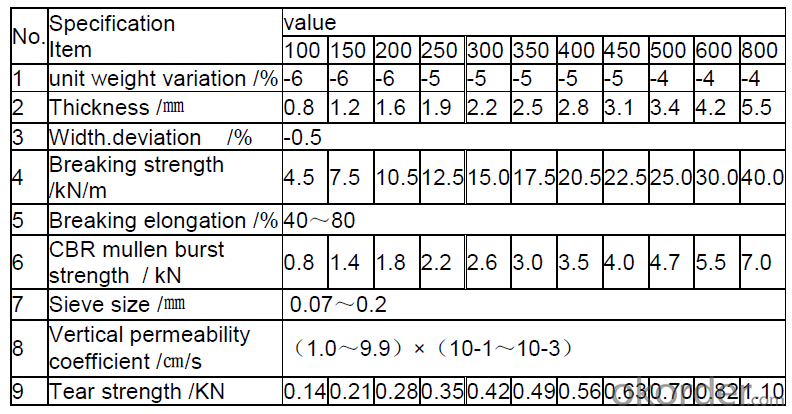

Specification

We try hard to cater our clients' need by offering Woven Geotextile. The offered product

is widely used for separation and stabilization in the construction of roads by preventing

the mixing of dissimilar soils allowing each soil layer in the road structure to function

as intended. This product is designed and manufactured by our adept professionals using

supreme quality metal alloys and pioneering techniques. In order to suit the varied needs

of clients, we offer this Woven Geotextile in different designs, finishes and dimensions

at market leading prices.

Features:

Perfect Finish

Easy installation

Resistant to corrosion

Resistant to prolonged exposure to high temperature

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Can geotextiles be used in geogrid reinforcement applications?

- Yes, geotextiles can be used in geogrid reinforcement applications. Geotextiles are often used in conjunction with geogrids to enhance their performance and provide additional support and stability. Geotextiles can help prevent soil erosion, improve drainage, and enhance the overall strength and durability of the geogrid reinforcement system.

- Q: 25og / m2 filter geotextile is what

- Is 250 grams of a square of geotextile for the role of trouble Huazhi geotextile material manufacturers to answer your questions

- Q: What is the meaning of the process equipment and equipment for producing geotextiles?

- What is the meaning of the process equipment and equipment for producing geotextiles?

- Q: Construction scheme of geotextile water filter

- Second, the design: program one: in strict accordance with the requirements of the national standard construction, 5-year warranty 1, in the smooth level of leveling the overall construction brushing JS waterproof latex or polyurethane waterproof coating, the thickness of the national standard 1 standard; Weak parts to do additional layer to strengthen; 2, do 20 ~ 30mm thick waterproof mortar protective layer, divided into two construction, layer waterproof layer of pulp interface; require nano-silicon waterproofing agent and expansion agent compound use. 3, backfill when asked not to smash the waterproof layer. 4, indoor ground practice ibid, the wall to do high 1m. Option 2: with reference to national standard requirements simple practice, the warranty period of 1 year 1, the overall construction of coated asbestos asphalt waterproof coating or waterproof cold primer, the thickness of the standard by the national standard 2; special weak parts to do additional layer to strengthen; Outside the protection, requiring the use of sticky or sticky sticky construction; 3, backfill when asked not to smash the waterproof layer. 4, indoor ground practice reference program one, the wall to do high 1m.

- Q: On the road where the laying of geotextiles should be how to shop

- Like roadbed fill, fill the junction and so on can be shop, a layer of a layer of shop, fixed good.

- Q: How are geotextiles affected by temperature variations?

- Geotextiles can be affected by temperature variations in several ways. Extreme heat can cause geotextiles to expand, leading to potential deformation or loss of structural integrity. On the other hand, extreme cold can cause geotextiles to contract, potentially reducing their effectiveness and compromising their functionality. It is important to consider the temperature range and choose geotextiles that can withstand the expected variations in order to ensure their long-term performance.

- Q: What are the considerations for geotextile selection in shoreline erosion control?

- There are several key considerations for geotextile selection in shoreline erosion control. First, the geotextile must have a high tensile strength to withstand the forces exerted by waves and currents. It should also be permeable to allow for water drainage and prevent the buildup of hydrostatic pressure. Additionally, the geotextile should be resistant to UV degradation and chemical exposure to ensure long-term durability. The choice of material and installation method should also take into account the specific site conditions, such as wave energy, sediment composition, and slope stability. Finally, cost and availability of the geotextile should be considered to ensure the solution is practical and feasible.

- Q: What are the challenges associated with the installation of geotextiles?

- Some challenges associated with the installation of geotextiles include ensuring proper alignment and placement of the fabric, securing it to the ground to prevent shifting or movement, and properly overlapping and connecting multiple pieces of geotextile to create a continuous barrier. Other challenges may include dealing with uneven or unstable soil conditions, working in difficult terrain or access areas, and ensuring the geotextile does not get damaged during the installation process. Additionally, the selection and installation of appropriate anchoring methods and the need for specialized equipment or expertise can also pose challenges.

- Q: How do geotextiles improve the performance of landfills?

- Geotextiles improve the performance of landfills by serving as a barrier that prevents soil erosion and filters out harmful substances. They also provide reinforcement and stability to the landfill structure, reducing the risk of slope failure or settlement. Additionally, geotextiles promote better drainage and help control leachate flow, improving overall landfill efficiency and environmental protection.

Send your message to us

Tejido Geotextil de Polipropileno No Tejido con Alta Estabilización y Estabilización

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 1000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords