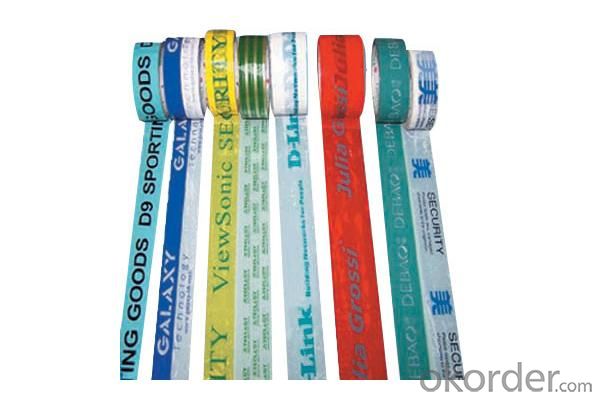

Custom Packaging Tape Rolls - Tape Customized Printed for Packing High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 34 roll

- Supply Capability:

- 456766 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Material: OPP film

Adhesive Side:Single Sided

Adhesive: Water Based Acrylic

Use: Carton Sealing and Packing,Light Duty Packing,Bounding,Holding and other office and household use

Design Printing: Offer Printing

Place of Origin: China (Mainland)

Model Number: Red opp packing tape Strong adhesive

Color: Clear, Tan, Yellowish, Brown, Yellow, White, Black, Blue, Green, Red etc.

Standard Size: 48mm x 66m, 50mm x 50m, 1.28m x 4000m, etc

Applications:

OPP Tape Customized Printed is economical for general carton sealing

Auto-packing machine

Gift Wrapping & Decoration

Bundling &Strapping

Meet all kinds of transportation convenientl

Production Description:

OPP Tape Customized Printed is made from OPP(Oriented polypropylene) film coated with acrylic adhesive.It is widely used for automatic carton Adhesive Packing Tape packing machines troughout various industries.

- Q: Can packaging tape be used for sealing plastic containers?

- Indeed, plastic containers can be securely sealed with the utilization of packaging tape. Specially designed to adhere to diverse surfaces, packaging tape effectively prevents spillage or damage to the container's contents. While commonly employed for sealing boxes in transit or storage, it can also be employed with efficacy on plastic containers. Nevertheless, it is crucial to ensure the tape is firmly affixed and all edges and seams are adequately sealed to uphold the container's integrity.

- Q: Does packaging tape come in different lengths for convenience?

- Yes, packaging tape does come in different lengths for convenience. Packaging tape is available in various lengths to meet the needs of different packaging tasks. The most common lengths of packaging tape are 55 yards (50 meters) and 110 yards (100 meters). These lengths are designed to cater to different packaging needs and ensure that there is enough tape to securely seal multiple packages without running out. Additionally, the availability of different lengths allows for flexibility in choosing the most suitable amount of tape for specific packaging requirements, ensuring convenience and cost-effectiveness.

- Q: How about the price of tape?

- Tape? A wide range, and you ask, how much is a bottle of drinks?. Ask for detailed answers

- Q: How do I remove packaging tape residue?

- To remove packaging tape residue, there are a few simple methods you can try: 1. Rubbing alcohol: Dampen a clean cloth or paper towel with rubbing alcohol and gently dab the residue. Let it sit for a few minutes, then wipe away the residue. Repeat if necessary. 2. Goo Gone or similar adhesive remover: Apply a small amount of adhesive remover to a cloth or paper towel and gently rub the residue. Allow it to sit for a minute or two, then wipe away the residue with a clean cloth. 3. Warm soapy water: Mix a few drops of dish soap with warm water. Dampen a cloth or sponge with the mixture and gently rub the residue. Rinse the area with clean water and dry it thoroughly. 4. Heat: If the residue is on a hard surface like glass or plastic, you can use heat to soften the adhesive. Use a hair dryer on a low setting and hold it a few inches away from the residue. Once the adhesive becomes soft, gently scrape it off with a plastic scraper or your fingernail. Remember to test any method on a small, inconspicuous area first to ensure it doesn't damage the surface.

- Q: Can packaging tape be recycled?

- Yes, packaging tape can be recycled. However, it is important to remove the tape from the packaging material before recycling.

- Q: Is packaging tape safe to use on delicate items?

- The safety of using packaging tape on delicate items varies depending on the type of tape and how it is applied. Certain packaging tapes are specifically made for delicate items, minimizing the risk of damage through features like low tack adhesive or gentle release properties. These tapes, commonly known as "low-tack" or "gentle" tapes, are often transparent. When using packaging tape on delicate items, it is crucial to apply it carefully and securely, avoiding excessive force or pressure. It is recommended to test the tape on a small, inconspicuous area of the item first to ensure it does not cause harm or leave residue. Moreover, it is advisable to wrap delicate items with protective materials like bubble wrap or tissue paper before applying the tape. This extra layer of cushioning and protection can be beneficial. If you are uncertain about the safety of using packaging tape on a specific delicate item, it is always best to consult with the manufacturer or seek professional advice. They can provide guidance on the most suitable packaging materials and methods to ensure the safety of your delicate items during transit or storage.

- Q: Is packaging tape safe to use on plastic outdoor furniture?

- Packaging tape is generally considered safe for use on plastic outdoor furniture. It is designed to adhere to different surfaces, including plastic. However, before using packaging tape on your outdoor furniture, it is important to take several factors into account. First and foremost, ensure that the plastic surface is clean and free of dirt or debris. This will enhance the tape's adhesion and prevent any harm to the furniture. Additionally, apply the tape evenly and firmly to avoid any peeling or lifting issues. It is crucial to remember that packaging tape is not specifically created for long-term outdoor use. Although it can be effective in temporarily securing items or protecting surfaces, it may not endure prolonged exposure to severe weather conditions or UV rays. Over time, the tape may deteriorate or leave sticky residue on the plastic furniture. If you require a more durable and weather-resistant solution, it is advisable to utilize specific outdoor adhesives or tapes specifically designed for this purpose. These products are typically made with materials that can withstand outdoor elements and are better suited for long-term use on plastic outdoor furniture.

- Q: What are the considerations for using packaging tape on glossy surfaces?

- When using packaging tape on glossy surfaces, there are a few important considerations to keep in mind. Firstly, the adhesion of the tape may be affected by the smoothness and slickness of the glossy surface. The glossy finish can create a barrier that makes it challenging for the tape to stick securely. Therefore, it is crucial to ensure that the surface is clean and free from any dirt, oils, or residue that could hinder the tape's adhesion. Additionally, the type of packaging tape used is important. Opting for a tape specifically designed for glossy surfaces, such as high tack or acrylic adhesive tapes, can provide better adhesion and longevity. These tapes are formulated to adhere well to smooth surfaces and offer stronger bonds compared to regular packaging tape. It is also advisable to test the tape on a small, inconspicuous area of the glossy surface before applying it extensively. This will allow you to gauge the tape's adhesion and ensure that it does not leave any residue or damage the glossy finish when removed. Furthermore, the temperature and environmental conditions should be considered. Extreme heat or cold can impact the performance of the tape on glossy surfaces. For instance, high temperatures can cause the adhesive to soften, leading to tape failure, while cold temperatures may make the tape more brittle and prone to peeling. Lastly, it is essential to handle the glossy surface with care to avoid fingerprints, smudges, or scratches that may diminish its appearance. Wearing gloves or using protective films can help prevent such issues. By considering these factors, you can increase the effectiveness and reliability of packaging tape on glossy surfaces, ensuring that your packages are securely sealed without compromising the aesthetic appeal of the glossy finish.

- Q: Is packaging tape safe to use on plastic hangers?

- Yes, packaging tape is generally safe to use on plastic hangers. Packaging tape is designed to securely hold items together and can adhere well to various surfaces, including plastic. However, it's important to consider the type of plastic hanger you have and the purpose for which it is being used. While packaging tape may work well for temporarily holding clothes on a plastic hanger, it may leave residue or cause damage if left for an extended period. It's advisable to test a small area of the hanger first to ensure that the tape does not cause any harm or leave any marks. Additionally, if the plastic hanger is being used for displaying or storing delicate or valuable clothing, it may be better to opt for gentle alternatives such as fabric-friendly tape or non-adhesive hanger attachments.

- Q: What are the benefits of using easy-release packaging tape?

- There are numerous benefits to using easy-release packaging tape, which can greatly simplify the packaging process. Firstly, this type of tape is designed with a low adhesion level, making it easy to remove without leaving any residue or damaging the applied surface. This is especially useful when packaging delicate or valuable items, as it guarantees damage-free removal. Moreover, easy-release packaging tape also saves time. It can be quickly applied and removed, increasing efficiency and saving valuable time for individuals or businesses that frequently package and ship items. Its user-friendly nature also reduces the risk of mishaps or errors during packaging, resulting in a smoother and more streamlined experience. Additionally, the ease of release provided by this tape makes it environmentally friendly. Since it can be easily removed without any sticky residue, it reduces the need for excessive cleaning or scraping, which can be time-consuming and may require the use of harmful chemicals. This not only benefits the environment but also cuts down costs associated with cleaning supplies and labor. Lastly, easy-release packaging tape offers versatility. It can be utilized for a wide range of applications, such as sealing boxes, securing packages, or bundling items together. The tape is often available in different sizes and materials, enabling users to choose the most suitable option for their specific needs. In conclusion, the advantages of using easy-release packaging tape include effortless removal without residue or damage, time-saving properties, environmental friendliness, and versatility. These benefits make it an excellent choice for anyone aiming to simplify their packaging process and ensure a stress-free experience.

Send your message to us

Custom Packaging Tape Rolls - Tape Customized Printed for Packing High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 34 roll

- Supply Capability:

- 456766 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords