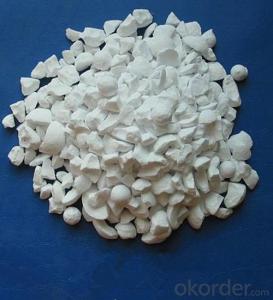

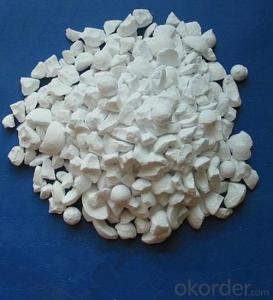

Raw Materials for Refractory:Tabular Alumina for High Quality Refractory Delivery

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tabular Alumina

Specifications

Tabular Alumina is high purity alumina processed by CE Minerals.Used as refractory,abrasives,polishing,grinding,ceramics.

Advantages

High Purity & Good Quality.

Good Hardness & High Heat-resistance.

Competitive Price & Reputable Supplier.

Typical Size

48mesh 100mesh 200mesh -35mesh 0.1-0.3mm 0-1mm 1-3mm 3-5mm

Guarantee Value

Item | Unit | Index | Typical | |

Chemical composition | Al2O3 | % | 99.00min | 99.5 |

SiO2 | % | 0.20max | 0.09 | |

Fe2O3 | % | 0.10max | 0.07 | |

Na2O | % | 0.30max | 0.20 | |

CaO | % | 0.1max | 0.03 | |

MgO | % | 0.1max | 0.06 | |

R2O | % | 0.3max | 0.20 | |

Magnestic | % | 0.02max | 0.01 | |

Bulk density | g/cm3 | 3.50min | 3.59 | |

Absorbing water rate | % | 1.0max | 0.7 | |

Porosity rate | % | 4.0max | 3.00 | |

Grain size | mm | 5-3mm,3-1mm,1-0mm,2-1mm,1-0.5mm, 0.6-0.2mm,0.5-0mm,0.3-0mm, | ||

Fine powder | mesh | - 220mesh, -325mesh | ||

Applications

Refractories & Abrasives.

Polishing & Grinding.

Ceramic material.

Applicated for high temperature engineering equipment, construction materials.

- Q: what's the standard of fireproofing material?

- Class A1 is divided according to the combustion performance of GB8624-2006 building materials and products. Specific technical index requirements are: 1, the temperature rise ≤30 degrees;mass loss rate ≤50%; combustion duration time is 0; 2, main components, overall products, gross calorific value of external secondary components ≤2.0MJ/kg; any inner secondary component ≤1.4MJ/kg; (there are difference between homogeneous and non-homogeneous). Z802 building materials noninflammability testing furnace has to be used for testing technical indicators mentioned in test 1, using Z805 building materials combustion heat value to test technical indicators mentioned in test device 2.

- Q: Where is the production of refractory manganese alloy manufacturers? Manganese is recommended between 63 and 70!

- The cut is relatively transparent if you jam, we have also used silicon manganese alloy

- Q: What are the meanings of azs, 34% and ec in fused brick?

- The fused brick, also called zircon corundum brick, is shorted as AZS for three chemical components in Al2O3-ZrO2-SiO2 ternary diagram. I don't know the meaning of EC.

- Q: What are the characteristics of thealuminium oxide refractory?

- Alumina refractory are characterized by uniform granularity, mobility, good dispersity. And it has good acid and alkaline slag erosion resistance, high strength, abrasion resistance, high melting point, erosion resistance , anti-flush and excellent thermal shock resistance.

- Q: How to hang the suspended brick in the refractory masonry?

- First you can fasten the girder and the suspended brick with screws, and then move them to the specified location by a crane. You can contact the refractory plant in Shanshan mountain, Ningxiang Countym, Hunan Province at 0731-7150098.

- Q: Which refractory material is better in China? Industrial furnace, mainly in non-ferrous industries, glass kiln, cement kiln business.

- Such solid nano microporous insulation material with nano inorganic refractory powder special, with a huge surface area, nano particles contact between the minimum point contact point contact thermal resistance is very large, the heat conduction effect of the material becomes very small, resulting in heat conduction coefficient of solid such nano porous insulation materials very small; nano pores formed of nanoparticles, the average size of 20 nm, and the average free path of molecular thermal motion at room temperature under static air is 60 nm, thus locking the air molecules in powder within nano pores, making the micro convection heat transfer effect between the stationary air molecules disappeared. The room temperature thermal conductivity of solid such nano microporous insulation material is lower than the static air; at high temperature, the main effect of heat transfer heat radiation, Good energy-saving insulation materials with nano microporous infrared additive special, stop at a high temperature and reflected infrared radiation, reduce the heat radiation effect to the lowest point, the radiation heat transfer coefficient of materials under high temperature is reduced to the lowest value.

- Q: How to determine the fire resistance rating of the aluminium-plastic?panel?

- The fire resistance rating of the aluminium-plastic?panel is determined by two indicators, namely national compulsory standard of GB8624 "Building Materials Combustion Performance Grading Method ", and GB/T17748 "Aluminium-plastic?Composite Panel National Standard" . Classifications of combustion performance of building materials in our country are as follows: A class: Incombustible building materials; B1 class: Flame-retardant building materials; B2 class: combustible building material; B3 class: flammable building materials. The fire resistance rating of the aluminium-plastic composite panel shuld be no less than B1 class. 1. Detection indexes and requirements of fireproof aluminum-plastic composite panel (B1 class): (1) Conduct the test according to GB/T8625-88, the average leftover length of each test specimen should be more than 150mm, (any test piece should have leftover length), and the maximum average flue gas temperature of each test should be no more than 200 ℃; (2) Conduct the test according to GB/T8626-88, flame hight indicators.

- Q: who knows how to classify the fire resistant levels of fireproofing material?

- Materials used in construction are called construction materials. The combustion performance of construction materials refers to all physic and chemical changes happened when burning or contacting fire, the properity is measured by combustibility of material surface and flame transmission, heating, smoke,charring, weightlessness, and the producing of toxicity resultant. Our national standard GB8624-97 classifies the combustion performance of construction materials into following several levels. Class A: Incombustible building material, class B1: Nonflammable building material, class B2: Combustible?building?materials, class B3: Inflammability construction materials, generally speaking: first fire resistant level construction is the mixed construction of reinforced concrete structure or brick wall and steel concrete structure; second fire resistant level construction is the steel structure roof truss, reinforced concrete column or mixed structure made by brick wall; third fire resistant level construction is the wood and brick made by wooden roof and brick wall; fourth fire resistant level one is the combustible?structure made by wooden roof, hard-comnustible component wall.

- Q: What is the new fireproofing standard of external wall thermal insulation materials?

- The new national standard "Fireproof? Specification of Building Design" (GB50016-2014) has been issued, it will be carried out from May 1, 2015. Compared with "Fireproof? Specification of Building Design" GB 50016-2006 and "fire?safety?rules of tall buildings design" GB 50045-95 (2005 edition), the major changes of new standard is the following: 1. It has combined with "Fireproof? Specification of Building Design" and "Fireproof? Specification of Tall Buildings Design", and has adjusted incompatible requirements between two standards, and has unified the classification of residential buildings in accordance with the building height; 2. It has increased two chapters including the fire-fighting rescue facilities and wooden structures, and has improved the requirements for fire fighting and rescue, and standardized the fireproofing requirements of wood construction; 3. Additional requirements for the fireproofing requirements of building external insulation system; 4. The fire-fighting equipment is written in a separate chapter and improve relevant contents; cancel the design requirements of fire water supply system and smoke control system, and they are regulated by the relevant national standards; 5. appropriate increase in the high-rise residential buildings and fireproofing technical requirements for high-rise civil building whose height is greater than 100m; 6. add the fireproofing requirements used by covered pedestrian during evacuation; adjust and add designers density of construction materials, furniture, lighting shops and exhibition hall; 7. add the fireproofing requirements of underground warehouses, logistics buildings, large combustible gas tank (zone), ammonia storage tanks, LNG storage tank, and adjust the fire?separation distance of liquid oxygen tank; 8. improve the relevant requirements to prevent vertical or horizontal spread of building fire.

- Q: what is the Specifications Grading for Fireproof rubber insulation materials ?

- External insulation materials, welded wire mesh matt external wall insulation, external wall thermal insulation mesh matt. 1,inorganic activel thermal insulation materials 2,silicate?thermal?insulation?material 3,ceramic thermal insulation 4, gelatine powder polyphenyl granule, 5,teel wire gauze picking cement cystosepiment(Estazolam platepowder particles)6 extruded sheetXPX. 7,Rigid polyurethane coating at the scene, Polyurethane insulation board8,rigid polyurethane foam,9EPS foam board roofing materials. 1, a ceramic insulation board 2, xps extrusion board 3, perlite and perlite brick 4, vermiculite and vermiculite brick heating, air conditioning Material: Phenolic resins, polyurethane waterproof thermal insulation integration, sponge rubber, polyethylene, polystyrene foam, glass wool, rock wool Steel material: Polystyrene, extruded sheet, polyurethane panels, glass wool carpets and the like. Five inorganic thermal insulation materials: Foam cement, DY inorganic active insulation system super thin vacuum insulated panel for building external walls .

Send your message to us

Raw Materials for Refractory:Tabular Alumina for High Quality Refractory Delivery

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t

- Supply Capability:

- 5000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords