Raw Materials for Refractory:Tabular Alumina with Good Delivery Time

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

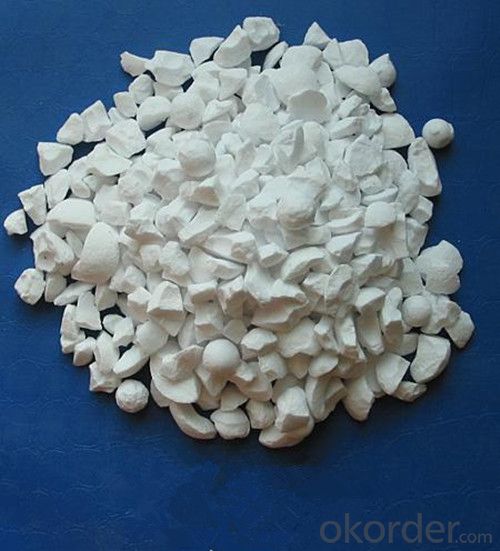

TA TABULAR ALUMINA wth GOOD DELIVERY TIME

White Tabular Alumina is pure alumina raw material, the mill, molding, drying, of 1970 degrees Celsius for ultra high temperature vertical furnace rapid heating, cooling and the formation of the density of the crystal, its microscopic phase is flake, called tabular corundum.

Product Description

| Index | FRT-Tabular Alumina T60/T64 | |||||

| Grain Size | -45 micron LI | -45 micron STD | -20 micron | |||

| AL2O3 | 99.50% | 99.50% | 99.10% | 99.30% | ||

| NA2O | 0.4% max. | 0.4% max. | 0.6% max. | 0.4% max. | ||

| SIO2 | 0.09% max. | 0.09% max. | 0.12% max. | 0.15% max. | ||

| FE2O3 | 0.02% max. | 0.02% max. | 0.3% max. | 0.02% max. | ||

| Bulk Density | 3.50G/CM3 min. | |||||

| Apparent Porocity | 5% max. | |||||

| Moisture | 1.5% max. | |||||

| Size | 0-1/1-3/-3-6mm 0-3mm, 0-2mm or as your requirements | -325mesh LI | -325mesh STD | -625mesh | ||

| Packing | 25kg per small bag, on wooden pallet with P/P cover 1MT per big jumbo sea-worthy bag or as your requirements | |||||

This product has the following advantageous chemical and physical properties:

High mechanical strength

High thermal conductivity

High resistance to thermal shock

High melting point

High electric insulation

High chemical stability

High resistance to wear

Picture:

- Q: hat kind of fire retardant materials are there

- There are many flame retardant plastics, which are modified on the basis of raw materials, such as flame-resistant ABS, flame-resistant HIPS, flame-resistant PP, flame-resistant PE, flame-resistant the PET, flame-resistant PBT, flame-resistant PC, flame-resistant PC/ABS alloy. Now there are mainly halogen flame retardant, though there are a lot of researches about halogen free flame retardant, the product stability and flame retardant effect remain to be improved. Testing methods of flame retardant materials are mainly: horizontal and vertical combustion, oxygen index method, NBS smoke box , thermal analysis, cone calorimeter, etc.

- Q: How about the prospect of refractory material?

- Area depends the market. Resource-based industry

- Q: What is the concept of lightweight refractory material?

- Lightweight refractory material has high porosity, mechanical strength and erosion resistance. Compared with normal refractory bricks, it is a kind of refractory material with large volume shrinkage in high temperature, low thermal conductivity and small bulk density. It is used as thermal insulation material in industrial furnace and other thermal equipments. It has poor wear resistancel.

- Q: What are fireproofing materials?

- Plants often use the fireproof sealing material with steel structures without much modification. All the panels that meet the first-order fire protection requirements can be fireproofing materials. Like gypsum boards, aluminum sheets and so on. . Coatings are usually those with fine powder, high density and good sealing. Hardeners mainly depends on specific requirements. .

- Q: What are the specific steps of stirring the steel ladle castable?

- Steps are as follows. 1 Compulsory mixer is used to stir the castable and bags, rope and other debris can not mix in the castable when stirred. 2, Castable should be unpacked on the scene. Stirred volume depends on the capacity of the mixer. Castable should be accurately measured and put into a blender. 3 The process of first dry mixing and then wet mixing is adopted. After the castable is added to the mixer, it is dryly mixed for 2 minutes, add about 5.2 to 5.5 percent of water and continue to add water while stirring. Water that is 80% of the total should be added, and then decide whether to continue to add or not depending on the consistence (noting that the water must be clean water and sewage can not be used). Then it is wetly mixed for 4 minutes and stirred for not less than 6 minutes at one time, until castable is even. In general, the bottom is slightly dry and the wall of the ladle is slightly dilute (the amount of water is only for reference). 4, The amount of water and mixing time should be controlled strictly when stirred to ensure that the needs of the consistency are met. If castable is too thin, it will seriously affect the quality of the material. The stirred volume, stirring time and water that is added should be consistent and they can not suddenly be thick or suddenly be thin. If the consistency does not meet the requirements, the castable should be put back to the mixer and stirred with appropriate water or dry materials. 5, It should be stirred evenly and casting should finish in 20 minutes, in order to avoid sclerosis, affecting structural strength of ladle lining 6, After each completion of construction, varieties of castable should be changed and the mixer should be cleaned 7, Stirring can stop in halfway. If the mixer breaks down and it can be repaired in a short time, some of the materials have to be removed before the machine is opened. If the machine can be repaired on time, castable refractory should all be removed.

- Q: Is aluminium oxide refractory material?

- Yes. It has high melting and boiling point, stable chemical?property. All refractory material almost contains aluminium oxide. Refractory materials have a large range and need specific requirements. Refractory material is divided into sizing refractory material, shapeless refractory material, ceramic fiber, refractory bricks and castable refractory. It can be subdivided according to temperature rating. Hope it is helpful to you.

- Q: What are fire?ratings of wall thermal insulation material?

- 1.thermal insulation material with grade A combustion performance: YT inorganic active insulation material for wall thermal,rock wool, glass wool, foam glass, foamed ceramics, foam cement, hole-closed perlite, etc. 2.thermal insulation material with grade B combustion performance: Extruded polystyrene board(XPS)after special treatment/polyurethane(PU) after special treatment, phenolic aldehyde,gelatine powder polyphenyl granule, etc. 3.thermal insulation material with grade B2 combustion performance: Molding polystyrene board(EPS), extruded polystyrene board(XPS), polyurethane(PU), polyethylene(PE), etc.

- Q: Which brand of refractory fiber hard thermal insulation board is better?

- Thermal insulation materials are divided into two types: porous material and heat reflecting material. The former uses the air void contained in the material to maintain thermal insulation itself for the heat conductivity coefficient of air or inert gas within the voids is low, such as foam material, fibers and other materials; the latter material has a high coefficient of reflection which can reflect the heat, such as gold, silver, nickel, aluminum foil or metallic coated polyester and polyimide thin films. Aerospace industry has strict requirement for the weight and volume of thermal insulation material, and it is often also required to has the properties of noise absorption, vibration attenuation, and anti-corrosion. Different aircrafts have different requirements for thermal insulation materials. Aircraft cabin and cockpit usually use foam, ultra-fine glass wool, high silica cotton to maintain thermal insulation. Earlier missile head uses phenolic foam plastic as thermal insulating material. With the application of polyurethane foam with good thermal endurance, the single insulating material has been developed to sandwich construction. A few millimeters foaming coating is coated on the skin outside the missile instrument bay, it is anti-corrosion coating at room temperature and when aerodynamic heating reach 200 ° C or more, it will generate foam evenly thus maintaining thermal insulation. Artificial earth satellite moves in an environment where the temperature varies from high to low, so it must use laminated thermal insulation material with high reflecting performance, which is usually made up of dozens of layers of aluminum film, aluminized polyester film, and aluminized polyimide film. In addition, the successful development of the surface thermal insulated tiles has solved the problem of thermal insulation of the space shuttle, it also marks a higher level of development of insulation materials.

- Q: Refractory inquiries

- Neutral refractory is refractory material which is difficult to react with acid or alkaline slag at high temperature, such as carbon refractory and chrome refractory. Some of the high alumina refractories are also attributed to this category.

- Q: How to divide fire resistant level of fire door?

- The classification of fire resistant level of fire door: Grade A is not less than 1.2h. Grade B is not less than 0.9h. Grade C is not less than 0.6h. It is suitable for fire door with different levels: Grade A: Equipment room (such as fire-pump room,power distribution room, generator room, smoke control fan room, etc) door, fire?compartment, door on firewall; Grade B: Eclosed staircase, front door of stair room, smoke-proof?staircase and fire elevator share lobby door, front door of fire elevator, household door which directly opens to front room or shares room; Grade C: The vertical shaft door, such as strong electric wells, weak electric wells, pipe shaft door and air conditioning facilities. I hope this information can help you.

Send your message to us

Raw Materials for Refractory:Tabular Alumina with Good Delivery Time

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords