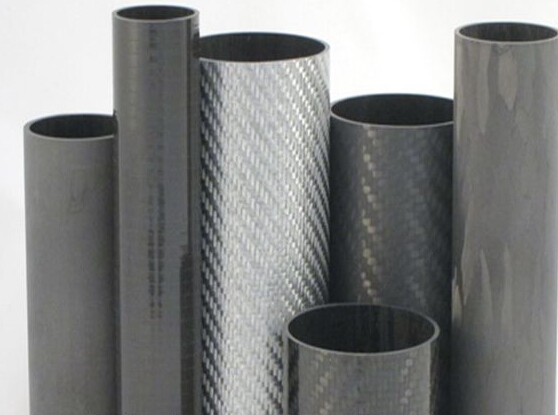

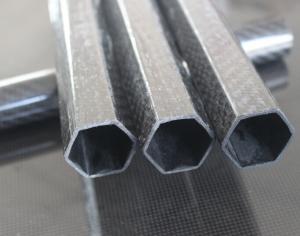

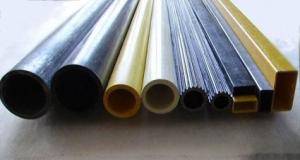

supplying different kinds of carbon fiber tube, light weight carbon fiber tube

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 /month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

3k China manufacturer carbon fiber tube

1.UV ressistance

2 non-magnetic elctromagnectic

3. enviromentally safe

Material Comparisons -

What are the benefits?

Our composite tubing, and in particularly our carbon fibre tubes, have significant advantages over most materials in terms of mechanical properties. The table opposite shows comparisons with other common materials.

Property | CF Fabric | CF Uni-Directional | Steel | Aluminium |

Density (g/cc) | 1.60 | 1.60 | 8.0 | 2.7 |

Youngs Modulus 0°(GPa) | 70 | 135 | 207 | 72 |

Youngs Modulus 90°(GPa) | 70 | 10 | 207 | 72 |

Ult. tensile Strength 0°(MPa) | 600 | 1500 | 370 | 240 |

Ult. comp Strength 0°(MPa) | 570 | 1200 | 370 | 240 |

Ult. tensile Strength 90°(MPa) | 600 | 50 | 370 | 240 |

Ult. comp Strength 90°(MPa) | 570 | 250 | 370 | 240 |

As can be seen, carbon fibre has excellent strength and low density. If these two factors are considered together, therefore looking at ‘specific strength’, then the benefits of carbon fibre look even more impressive. This is highlighted in the graph opposite.

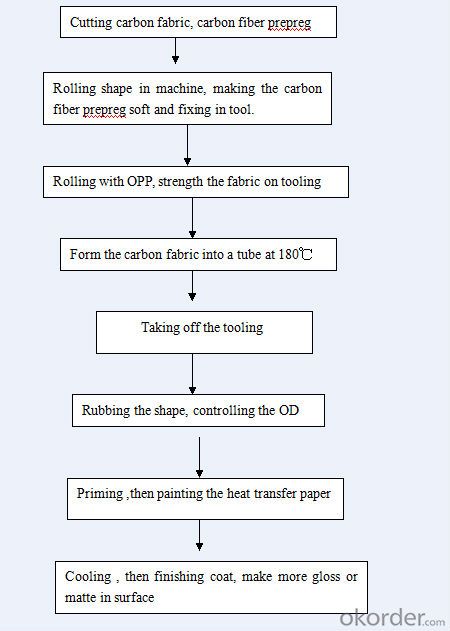

Manufacturing Process -

How are the tubes made?

When the laminate has been designed and verified by our engineers the individual patterns are fed to our 5 metre long CNC cutting table which cuts out each pattern precisely. The materials we use are cloths which already have the resin matrix impregnated in to them, known as pre-pregs.

Next, these prepreg layers are wrapped around the male tooling (mandrels) which determine the Inside Diameter (ID) of the tube. These patterns are wrapped in an exact sequence on our machine driven rolling table to ensure consistency and accuracy of the lay-up.

The tubes are then subjected to a high temperature curing cycle under pressure in our electronically controlled ovens and finally removed from the tooling using a hydraulically powered puller mechanism.

Once complete, the raw blank is then ready to be machined and finished in line with the design specification.

The process of carbon fiber tube

Marine

With over 60 years of collective marine experience we have a significant insight to this industry. This, coupled with our vast knowledge of composites, is invaluable given the diverse nature of composite marine applications.

We produce tubing for all types of marine applications, from small dinghy tiller extensions, paddle shafts, and spars up to one-off tubing for large yacht masts.

The flexibility of our manufacturing process is one of our distinctive qualities in this area:

Able to make tapered tubing which is ideally suited for mast applications.

We can make oval tubing often sought after for masts or booms requiring differential properties in different axes.

Tubes are made with epoxy resin systems which have virtually zero water absorption making them more suitable for marine based use than lower quality tubing made with vinylester or polyester resin systems.

We have in-house paint facilities and are able to finish tubes with UV stable paint systems, protecting the tubing against inevitable long exposure to the elements.

photos:

We have established a considerable presence within the automotive industry supplying companies from mainstream car manufacturers to niche motorsport organisations.

We supply the majority of Formula 1 teams starting on the grid this season

We are at the forefront of composite innovation.

Experience handling and stocking very high tech materials.

Other automotive projects include:

Exhaust sleeves for both cars and motorcycles

Pit equipment

Suspension struts

Chassis members

- Q: How are the sleeve couplings joined?

- The clamping ring is inserted into the outer wall of the steel tube by the action of the nut and the main body so as to form a seal

- Q: The collar on the kit is supposed to poke a hole directly into the pipe, then feed water into the line that attaches to the fridge. I went to do this the other day and found that the pipe underneath the sink is made of silver mesh. (Braided?) So is that going to work? Or will putting the collar into the line going to make it leak?

- Sounds like the tires haven't been rotated and they are cupped move the front tires to the rear, switching sides, and the back ones straight to the front.. if the noise continues on the right front you have a bearing, or cv joint problem, if it moves to the left rear you have a bad tire, if it just moves to the rear, it needed rotation. If the car doesn't pull to one side, alignment is finealthough hitting holes and speed bumps hard, could cause the toe-in to be off..

- Q: what is &curved space&?

- 1. The product. Are they making a product that has a market? They can make the best iron pipe fittings in the world, but if every body is using plastic pipe fittings, that company is not long for this world. 2. Customer base. Is 90% of their business generated by a single customer?? Stay clear! If that company would have financial difficulty, it could wreck the best companies.and if it were to lose that customer, lights out! 3. Debt to equity. Is the co heavy with long term debt, and are accounts payable current? Then, the co has adequate cash flow to pay its bills. 4. Legal issues. Not necessarily lawsuits, but are they disposing of waste in a questionable manner? Is their facility surrounded by fields that are giving way to housing developments? true, the co was there first, but all it takes in one person buying a new house who is going to complain about heavy trucks going in and out of your property. 4. Are their workers represented by a Union. Non union work forces are more flexible. 5. ifs there room for future expansion? There are others, but these , to me, are very important.

- Q: my 10 y/o little sister used to go on zwinky but i noticed people were saying 'sex party at my house!' and i was quite shocked as she told me it was just a chat room kind of thing that all her friends went on. our mom banned her but im sure there are loads of other people her age on zwinky who shouldnt see that kind of stuff that is supposed to be really safe.

- The 3500 rotor head has a 3/4 female thread to tie into. I would use all 1/2 PVC for the main line with 1/2x1/2x3/4 sst fittings with 18 of 1/2 funny pipe then a 3/4 funny L fitting to your heads. 40 feet apart is a bit too far. Try to space no more than 30 feet apart. You can buy special inserts for the heads that can give you different gallons per minute (usually 3 to 4 GPM) and angles of water flow. To check water flow from a faucet. Fill a 5 gallon bucket. If it takes 15 seconds, you have 20 Gallons per minute.

- Q: What are the differences between hydraulic couplings and fittings and elbows?

- The hydraulic pipe connection includes hose joint and steel pipe jointThe connector body does not include the nut clamp. There are straight through fittings, elbows, and 45 degree joints, etc..Elbows generally refer to joints of 90 degreesMy side is to do this piece, the United States PARKER Parker imported hydraulic hose, joints, quick connectorThere's contact information in the comments, thank you!

- Q: Classification of pipe couplings for hydraulic couplings

- Non standard type pipe joint, flared pipe joint, right angle pipe joint, rotary pipe joint, quick joint, stainless steel pipe joint, copper joint.

- Q: I own a 2001 Toyota Corolla with manual locks and windows, and I was wondering if it was possible to install power windows and locks and keyless entry, and if so, how much it would probably cost.

- It's totally depends on the amount of fixtures and connectors you need. Every job is different and the amount of material as well. You never stated who is doing the job. If you are doing it, you must have the proper skills and tools to complete it. On the event that you are doing it, just measure and buy enough connector fittings and pipes to complete the job. If you are missing something, just go back to Lowe's or Home Depot and keep buying as needed. The store will take back any unused material and give you credit for. If you do not have neither tools or skills to do it yourself, then you must call one of those money hungry plumbers in town to do it for you! Good luck!

- Q: What is the liquid used in the fire hose joint?

- Most of the interfaces used for the groove connection are diluted detergent or soapy water

- Q: in my assignment im asked to explain about the difficulties and misuses of lightning rods, ive looked everywhere on the net for them but im not finding

- If you have polybutylene pipe it is recommended that you change the pipe to either copper or PVC. PB has a history of failures which can cause major water damage. PB pipe has been the subject of many class action law suits and your insurance may not cover water damage caused by PB pipe failure.

- Q: What is the size of the PVC pipe joint?

- [1] the PVC joint size is in inches, 1 inches =25.4 millimeters.[2] PVC: polyvinyl chloride (English: PolyVinyl Chloride abbreviation: PVC) is a use of a chlorine atom to replace one of the hydrogen atoms in polyethylene polymer material. PVC is an amorphous white powder with less degree of branching

Send your message to us

supplying different kinds of carbon fiber tube, light weight carbon fiber tube

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 10000 /month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords