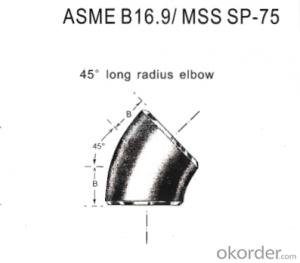

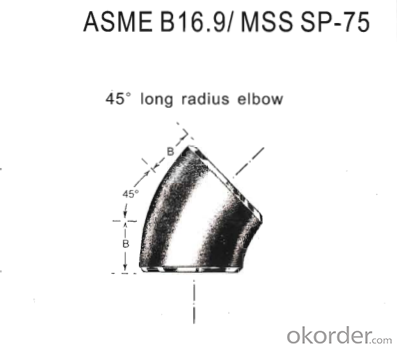

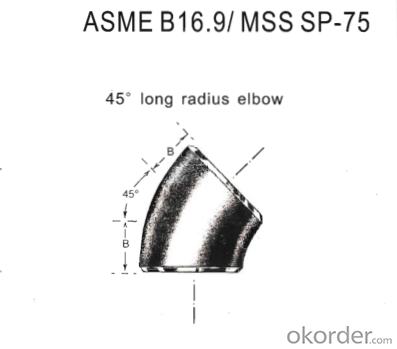

Stainless Steel Pipe Fittings Butt-Welding 45° Long Radius Elbows

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features standards and products of our butt welding fittings:

Features of butt welding fittings:

1. High class materials

Our products only use high class raw materials of carbon/alloy steel pipes made from NKK or MANNESSMANN equipment for ordinary, high pressure, low/high temperature,boiler and other purposes.

2. Uniform wall thickness and perfectly round

This can be achieved by our particular technical knowhow and our quality control program.

3. Accurate dimension

Efficient piping work can be made only with fittings of correct dimensions and shapes. Our fittings are finished to have accurate straight/ plane ends, beveled angle...etc. to applicable standards by means of two or three spindle beveling machines.

Standards of butt welding fittings:

Our welding fittings are manufactured in compliance with the following appliance standards:

ASME B16.9 ASTM A234 MSS-SP43 WPHY60 JIS B2311 DIN2605

ASTM A403 MSS-SP75 WPHY65 JIS B2312 DIN2606

ASTM A420 WPHY42 WPHY70 JIS B2313 DIN2616

ASTM A860 WPHY52 DIN2615

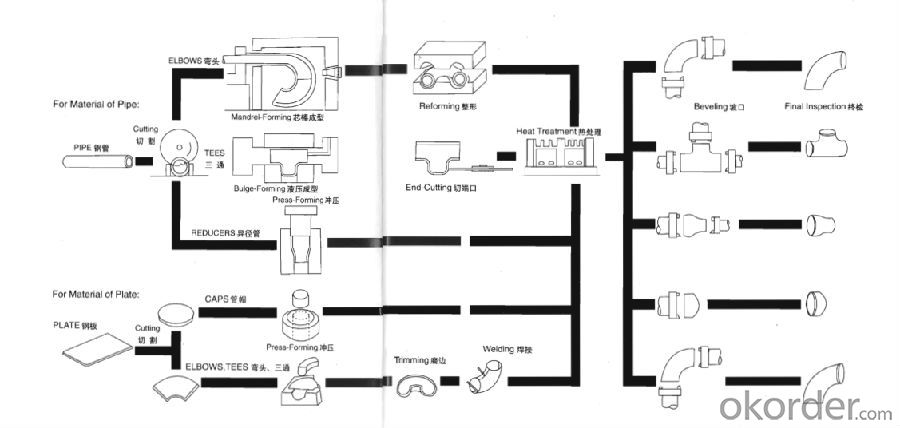

Manufacturing method and process:

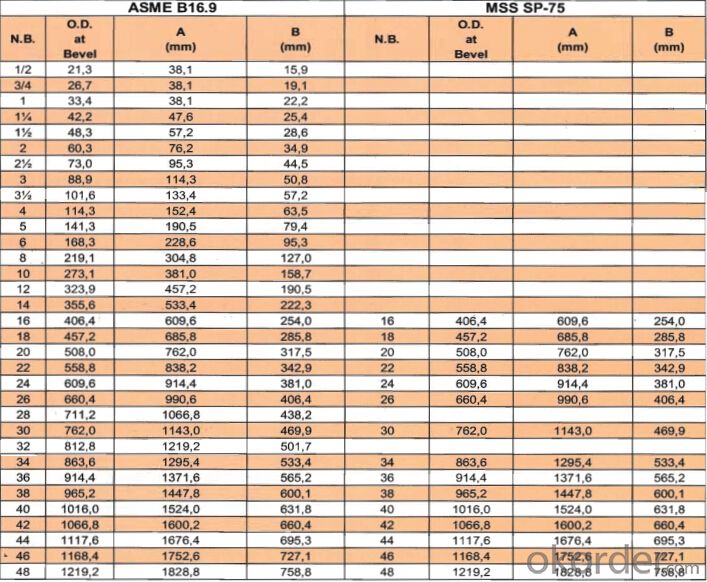

BUTT-WELD FITTINGS ASME B16.9/MSS SP-75

45° Long radius elbows:

Packing of butt welding fittings:

FAQ of butt-welding fittings:

1) Q: What’s your main product? Which kinds of products are more competitive in your product range?

A: Our main products are steel flanges, pipe fittings and steel pipes.

Competitive Items: flanges in stainless steel, carbon steel, alloy steel and punching carbon steel

Butt welded pipe fittings in stainless and carbon steel

2) Q: what’s your largest size of flange and fitting? How long is the production cycle?

A: The largest flange we could produce is 80’’ and the largest fitting is 50’’.

In general, we spend 20-25 days in a 20-ton order. If necessary, we could make it shorter.

3) Q: Could you produce according to the drawings?

A: Sure. We could produce according to the provided drawings, which include forged and casted items.

4) Q: What kind of certificates do you have?

A: We have ISO, TUV, API,SGS,BV etc. fittings in stainless and carbon stee

Malleable Iron ,Stainless and carbon steel pipes

- Q: my grandma's dog is afraid of smoke detectors and wont stop panting and shaking. he is constantly under her feet. he is even afraid if he hears it on television

- It is hard to say just yet, before the game is released, but judging on the previous game, it will be lengtheir single player experience than your average game. Also don't forget that you can play it twice (as a good character and an evil character) and that Fable II will also have coop play, which may extend the game's longevity even further. I am confident that Fable II will have a good gameplay length for its money.

- Q: Do you have DN150-DN80 variable diameter steel pipe joint?

- Such components generally belong to standard parts, which is a national standard. It's easy to procure in the market.See details: "GB/T 12459-2005 steel welded seamless pipe fittings"The L length of DN150-DN80 is 140mm, and is H in the national standardSee below:

- Q: Its said the highest risk of death in a aircrash is fire/smoke. why dont airlines supply fire/smoke blankets?

- both? it varies, i think from car to car in my car they are by the stereo above the gas pedal and brake.

- Q: I keep seeing those movies where the killer has a car that is filled up with water on the inside and their victim is inside dead as if they were trapped inside the car and drown. But the car isn't submerged in a pool or lake it is as if the killer put a hose in it and drown them. Can it be so simply done or do you have to water seal your car get all fancy like that? Just the random thought of the day.

- Why you smoking drugs in the house for?

- Q: I go to school and play ping pong monday thrrough friday. I had a paddle in my backpack and it is kind of tight backpack and eventually my paddle got warped. I invested into a pretty nice paddle and dont want to have the paddle bend or warp in any way. I dont want to get a new backpack or carry the paddle everywhere I go cause I will forget it somewhere and looks weird lol.I saw many cases on , but I dont know if it will help prevent my paddle from bending like maybe a hardcase to would be great.Any recommendations?

- The 'wage gap' is a bout of bullshit statistical theatrics which ignores time worked, seniority, education, training, career choices, or performance. If a company could get away with paying a woman seventy odd cents on the dollar to perform / produce the SAME work that a man would get $1.00 for, NO company would ever hire men and any company still stupid enough to hire men would be out of business in no time because their labor costs would be a whopping 30% higher than their competitors. Feminists LOVE to ignore the obvious. I await some evidence or proof positive that the wage gap is due to discrimination. You would think after FIFTY YEARS of feminism, they would be able to produce a SHRED.

- Q: I've always wondered that when I see people wearing hats, if the hat prevents the sun rays from penetrating the skin.

- I personally say gloves when you are required to manipulate things while wearing them in public. Mittens are purely for function, I think, because it does keep your fingers closer to each other and the blood is circulating closer. But if you're outside for an entire day and wearing mittens, your fingers don't have room to move and you might get cramping from lack of mobility (which is what regular gloves permit.) So, for strictly warmth, mittens, but to function and keep all your fingers mobile and moving all the time, gloves.

- Q: These equipments could have saved houses where wild fires are possible. Developers should be required to install these equipments or at least backyard fire hydrants where necessary.

- Yes, the event horizon is more or less spherical. I've wondered how the disk image got so popular myself. I guess it's because the scientific impressions always picture the accretion disk, and your average person just thinks it's a representation of the black hole itself. It might help with all the questions of 'what's on the other side of a black hole' if people understood it's not actually a 'hole.' They get the disk shaped idea in their head and they think it's like a portal to somewhere else, when you pass through the disk you end up in another place. Maybe if people learned to envision them as spherical they'd realize that you don't go 'through' a black hole, you go IN it.

- Q: I'm in an apartment, and have been having trouble with my toilet fill valve. I had a leak into the tank which necessitated me turning off the toilet valve several times, and I guess that loosened the nut on that valve a bit, because I got drips coming out of that valve onto the floor. Instead of calling maintenance, I decided to try and fix it myself, and took a wrench to the nut on the toilet valve. I turned it and stopped the leak, but I also turned the toilet valve about a centimeter to the right, meaning that it pivoted about a centimeter clockwise in relation to the wall. I have no outward signs of a leak inside the wall, nor can I hear any leakage, but I'm just concerned that I may have damaged the piping in the wall somehow, and that it might be dripping or leaking without me knowing it. How is the piping usually set up inside the wall for a toilet valve?

- Why does everyone keep forgetting that the college football season is now 12 games? As for the 'Cocks, their non-conference schedule outside of Clemson, like every other SEC school, is a joke (Wofford, Florida Atlantic, Middle Tennessee), so all of those are wins. They go to Clemson, and that's always a war. In conference, they avoid Alabama, LSU, and Ole Miss. They have possibly the easiest road schedule in conference possible, going to Mississippi State, Kentucky, Vandy, and Florida (well, Florida's a loss, but the other three should be easy wins). Georgia, Tennessee, Auburn, and Arkansas come to Columbia. I'm going to say 9-3, with losses at Clemson, at Florida, and at home to either Georgia or Auburn.

- Q: would you think that person was dumb?i got fired today and i dont understand whyi started in june and at first it was hard, i worked at the back making all the burgurs, so it took a while to learn what goes in eachbut i felt i was getting better everytime i went thereand its not like i stole anything, or came late to my shifts, i was there on time everyime i had a shiftdo you think its because i wasnt good at communicating? i stuter a lot and talking to new people is hard, but like i said, i was getting better everytime i came

- try it in real life and use those resources to answer your question.

- Q: I have a large collection of LPs, many of which are out of print. I'm not a rare LP collector as such but enjoy the music very much and don't want to lose the music I've amassed. What are some opinions as to the risk(s)/benefits of recording these onto CD-R and giving the bulk of this space hogging vinyl over to the flea market?

- Perhaps those guys are expressing their true feelings, as opposed to putting females down. Anyway, why bother to ask ? You don't even like men to begin with. Or is this just one of those issues where females' lack of power over men is looked upon as something lacking in us men ? And that BS about butch lesbians and studs getting hit on by guys is unbelievable. Or have you taken a good look at any of them lately ?

Send your message to us

Stainless Steel Pipe Fittings Butt-Welding 45° Long Radius Elbows

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords