High Strength and Light Weight Carbon Fiber Tube

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description for Carbon Fiber Tube

Our composite tubing, and in particularly our carbon fibre tubes, have significant advantages over most materials in terms of mechanical properties. The table opposite shows comparisons with other common materials.

Property | CF Fabric | CF Uni-Directional | Steel | Aluminium |

Density (g/cc) | 1.60 | 1.60 | 8.0 | 2.7 |

Youngs Modulus 0°(GPa) | 70 | 135 | 207 | 72 |

Youngs Modulus 90°(GPa) | 70 | 10 | 207 | 72 |

Ult. tensile Strength 0°(MPa) | 600 | 1500 | 370 | 240 |

Ult. comp Strength 0°(MPa) | 570 | 1200 | 370 | 240 |

Ult. tensile Strength 90°(MPa) | 600 | 50 | 370 | 240 |

Ult. comp Strength 90°(MPa) | 570 | 250 | 370 | 240 |

As can be seen, carbon fibre has excellent strength and low density. If these two factors are considered together, therefore looking at ‘specific strength’, then the benefits of carbon fibre look even more impressive. This is highlighted in the graph opposite.

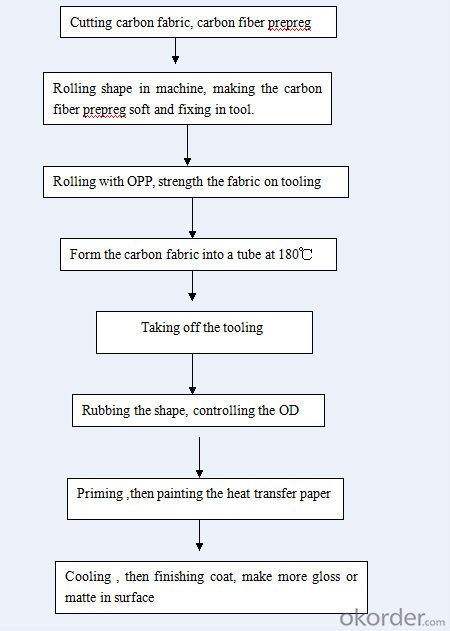

2.Production process

When the laminate has been designed and verified by our engineers the individual patterns are fed to our 5 metre long CNC cutting table which cuts out each pattern precisely. The materials we use are cloths which already have the resin matrix impregnated in to them, known as pre-pregs.

Next, these prepreg layers are wrapped around the male tooling (mandrels) which determine the Inside Diameter (ID) of the tube. These patterns are wrapped in an exact sequence on our machine driven rolling table to ensure consistency and accuracy of the lay-up.

The tubes are then subjected to a high temperature curing cycle under pressure in our electronically controlled ovens and finally removed from the tooling using a hydraulically powered puller mechanism.

Once complete, the raw blank is then ready to be machined and finished in line with the design specification.

The process of carbon fiber tube

3. Features for Carbon Fiber Tube

With over 60 years of collective marine experience we have a significant insight to this industry. This, coupled with our vast knowledge of composites, is invaluable given the diverse nature of composite marine applications.

We produce tubing for all types of marine applications, from small dinghy tiller extensions, paddle shafts, and spars up to one-off tubing for large yacht masts.

The flexibility of our manufacturing process is one of our distinctive qualities in this area:

Able to make tapered tubing which is ideally suited for mast applications.

We can make oval tubing often sought after for masts or booms requiring differential properties in different axes.

Tubes are made with epoxy resin systems which have virtually zero water absorption making them more suitable for marine based use than lower quality tubing made with vinylester or polyester resin systems.

We have in-house paint facilities and are able to finish tubes with UV stable paint systems, protecting the tubing against inevitable long exposure to the elements.

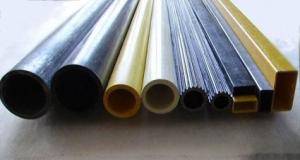

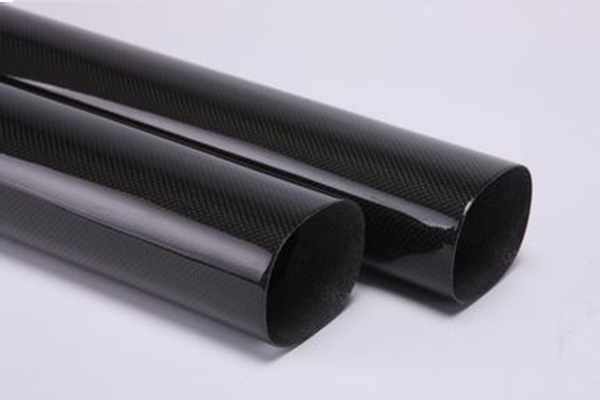

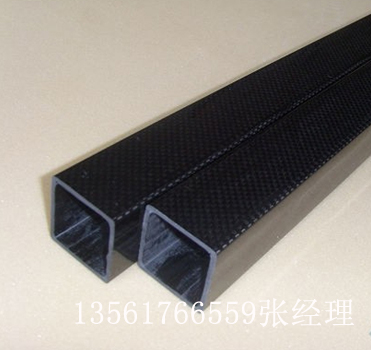

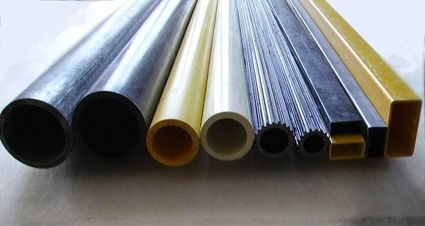

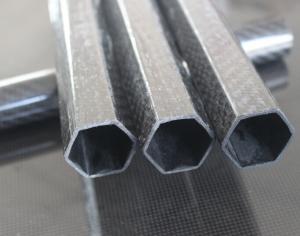

4. Photos for Carbon Fiber Tube :

- Q: PVC how to deal with leaking water in the upper opening of three pipe joint of launching pipe?

- When you take it back, stop the water and dry the gap with a dry cloth. Cool the water in the gap. Then mix the UPVC glue with the PVC resin powder into the slurry and fill it in between the cracks until it is filled

- Q: What are the types of hydraulic couplings?

- Is a flat +O ring, C - like Japan, spherical ring - free, H - like Germany, 24 degrees cone +O - shaped ring.Each has hundreds of models, depending on the manuals and samples.

- Q: Why does it take so long to extinguish forest fires?

- Buy a book on basic residential plumbing and DIY it of course! I assume you're talking about drain plumbing, not supply plumbing. Basically you'd find a point at which you're confident in the drain and make a plan for replacing all the drain from the toilet to that point. Its going to involve PVC pipe, fittings, and glue, a hack saw, file, screw driver, and possibly a rubber compression sleeve. That's just for the pipe. You'll need access to the drain for the entire length which might mean cutting into drywall, flooring, etc. Provide more details and maybe some pictures for more specific advice.

- Q: why are lightning rods pointed?

- the city is accountable because of the fact they made the hearth combatants participate interior the parade. As you mentioned they have been instructed to my their better. They have been needless to say partaking interior the parade and not offering any variety of particular accountability, returned making the city accountable. They have been striking in following the order given to them. in the event that they volunteered to artwork some particular accountability and that they have got been given harasses, that become their determination to artwork it and the city would not be accountable at that factor. I accept as true with their lawsuit. As for the different posters who say the city isn't accountable, yet people who have been taunting the hearth combatants, you're incorrect. The firefighters did no longer volunteer to be interior the parade, they have been instructed to do it via a supervisor. The order given isn't unlawful, so they had to conform. Now, in the event that they chosen to be interior the parade, then th city would not be answerable for the harassment. additionally, think of approximately this. A cop gets right into a automobile pursuit with yet another automobile. the different automobile chooses to no longer cease at a cease sign and runs the intersection, hitting and killing yet another motorist. Why does the victims relatives sue the police branch and not the driving force? that's not the police departments fault the driving force desperate to run from the police and not cease, why are the cops being sued?

- Q: Wouldn't it be funny if Cincinatti came out of the tunnel and all the offensive players had face shields?

- This screams of discrimination. I would call the school board and a lawyer. Everyone here is correct. They cannot discriminate because of medical conditions, they must attempt to accommodate by law. You boy deserves to go and is well old enough to take care of his own accidents at night. I would suggest adult diapers that fit well and can hold a lot, try them at home for a few nights first so he's comfortable, and see if they leak. These would be easier to deal with than him peeing in his underwear or pj's and wet sheets. A good sleeping bag that's waterproof, and he is all set. He can explain the diapers to his tent mates and say they are from his doctor and he is waiting for surgery later. Most would understand and probably look out for him. Don't stand for this for one minute!!!

- Q: I mean like if you count the seconds inbetween each lighting flash, is that really how many miles you are from the center of the storm???

- Buried (with Ryan Reynolds) Panic Room (with Jodie Foster) Cellular (with Kim Basinger) One Hour Photo (with Robin Williams) 127 Hours (with James Franco) Man on The Ledge (with Sam Worthington)

- Q: I heard once it was 68% or something.

- Contact a lawyer anyway and ask for advice on what to do and after that the court house should be able to appoint you a lawyer but that might just be if you are arrested another thing u can do is to report it to your company director of HR (human resources) good luck

- Q: Does anyone know how to set a Trek Dreadlock (bike lock) 4-digit combination?

- Just accept her gift, use what you want and store the rest away. There is nothing wrong with second hand clothing or baby toys. Most baby things that people sell at garage sales are barely used. My husband makes six figures and we still will occassionally pick up a cute outfit or baby item at a consignment store. Why not? Sounds like your MIL is just trying to help.

- Q: I am making a project where I am glueing with a glue stick pictures on stock-card(thick paper) onto a poster board but they are not perfectly flat. Can I iron them or will it cause a problem like the ink melting?

- You should have a meeting, show her the evidence and then tell her what you are going to do. Before the meeting decide if she can get another job or at least is she married w/kids and determine if you fire her she will get unemployment compensation. Also know you should not give her a bad reference and just move n if you want her to resign. So several options are there.

- Q: Is it used in Thai or Balanese cooking and if so, how please?

- You can use the adapter at the dryer or on the wallone way it's a reducer from your dryer where you hose is a 3 hose. or it's a reducer at the end of 4 hose to fit the 3 wall mount. Either way it will be OK.

Send your message to us

High Strength and Light Weight Carbon Fiber Tube

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords