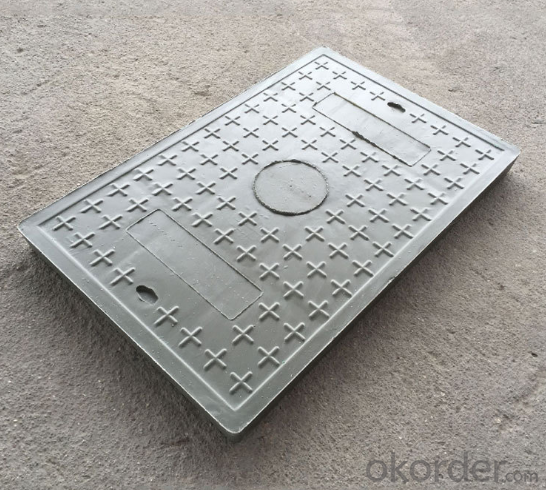

Supply Heavy Duty Cast Iron Manhole Cover EN124 B125

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 115 set

- Supply Capability:

- 4100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

1) Product information

Manhole Covers are manufactured for construction and public use. Manhole Covers shall be smooth and free from sand holes, blow holes, distortion or any other defects

2) Material

a) Ductile Iron GGG500-7 & 400-12

b) Grey Iron GG20

3) Designs

a) EN124 A15, B125, C250, D400, E600 and F900

b) A60005 for casting design

c) Major standards designs available

d) As per customers' drawings or samples

4) Process

a) Molding boards

b) Green sand with hand molding

5) Coating

a) Cold applied black bitumen

b) Without coating

c) Coating as per customers' requirement

6) Different accessories are available

Pictures

Advantage of ductile iron

Higher quality /higher tensile

Higher security /long life

Packaging and Shipping

Packaging: Details Pallet with bubble film, Carton or with pallet,

Delivery Detail: 8 days if your order is 20"container

Our Services

1. Sample is available for free.

2. OEM and ODM are welcome.

3. Free charge of design labels and cartons.

4. Our products: produced by the hydraulic Press.Meanwhile, a number of experienced workers do the strictly Quality control and have production tracking program.

5. Our price: we are the factory, we provide the most competitive price with good quality, and large order quantity will get big support by us!

6. Professional technical support with free charge.

7. After the cooperation: Any of your problem will be solved within 24 hours.

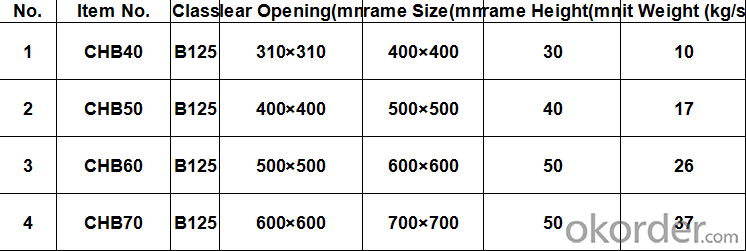

Specifications

Company Information

CNBM International Corp., established in 2004, is the business entity for trade and logistic of CNBM Group.

CNBM International is highly recognized by its business partners and clients all over the world and has established good business relationship with the customers in over 160 countries and regions all over the world.

CNBM Ductile Iron manhole cover A15-F900 complying with EN 124 Standard

FAQ

1.Q: Are you factory ?

YES! We are a professional ductile iron &gery iron casting Factory in China.

2.Q: How long can you make your quotation:

Within 3 workdays after received your detailed product information

3.Q: Do you provide OEM Service?

Yes, we provide OEM Service.

- Q: Why does the precision casting factory not usually make iron castings?

- The so-called precision parts is the size, roughness requirements of the piece. Cast iron parts generally do not reach the accuracy.

- Q: What are the factors affecting the machining process of the casting material and structure?

- As for the metallographic structure, usually the finished products after casting are treated by heat treatment. The mechanical properties of the carbon steel after heat treatment (quenching and tempering) are detected. The stainless steels are treated by heat treatment (solid solution, etc.) and the metallographic structure is analyzedThere is a lot of talk and a bit of confusionIf you have a specific brand, you can search for Baidu or buy tools

- Q: How to improve the surface roughness of casting parts?

- One is to improve the accuracy of the model; the two is to improve the molding sand mesh. How much is the other relationship?.

- Q: What are the effects of stiffeners on castings, or on welded parts (for 2 tons or less), casting or weldments on stiffeners?

- Please consider the following points:1, batch: if the product batch is very large, casting will certainly have advantages, cost sharing will be very low. If less, it is recommended to use weldments.2. Reinforcement structure: if the structure is relatively simple, it is recommended to use welded parts, complex, preferably casting.

- Q: What is the difference between forging parts and casting parts?

- The forging can guarantee the continuity of the metal fiber tissue, make the fiber structure of the forging keep the same shape as the forging, the metal streamline is complete, the tissue is compact, and the mechanical property is good. To ensure that the object has good mechanical properties and long service life, the processing of objects sharp, durable, high strength, first-class quality.

- Q: Selection of hydraulic press is the casting parts and steel plate welding, how to choose?

- Casting parts in one shape, the overall processing in this regard than steel plate welding better. The same price is much more expensive than steel. Large hydraulic presses seldom have casting parts.

- Q: After reaming, the roughness can reach several levels, that is to say, the sample.Casting parts in rocker arm drilling, reaming, roughness, block. After reaming, the roughness can reach several levels, that is to say, the sample.

- Not processed, do not understand your problem... There's something wrong with the drilling machine. Please call me

- Q: Question, such as title, I hope I don't copy the definition of rolling and casting in Baidu encyclopedia, thank you

- The performance is too extensive, I think the following several people all fall into the erroneous zone directly, the performance includes a series of aspects:Mechanical properties: tensile strength, yield strength, elongation and contraction ratio of section and impact toughness after etc.

- Q: Which master knows how the casting tolerances for malleable iron, gray iron and ductile iron should be chosen? Hurry up, thank youCan you provide a tolerance scale for castings, please?

- Our country has a national standard for casting tolerance levels. This national standard applies to you in malleable iron, grey cast iron, and ductile iron.

- Q: What reason is the bronze statue choking fire?

- The casting process in boiling phenomenon, is the setting of the exhaust hole positioner position or number is not reasonable, the air cavity can not be discharged, overwhelmed by a material inlet, reflux, change mould, sincerely help you look forward to adopt,

Send your message to us

Supply Heavy Duty Cast Iron Manhole Cover EN124 B125

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 115 set

- Supply Capability:

- 4100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches