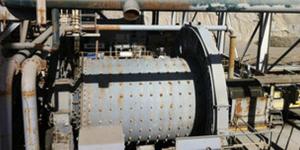

Superior Steel Forged Grinding Ball For Plant Cement and Mine

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

(1).Raw material: Round steel ,the raw material of forged balls ,are totally ordered from our national large -scale steel mills. We can also provide special processing as per special requirements of different grinding balls

Materials.

(2).Scientific Proportioning :Rational chemical composition is gradually optimized and formed by our technical staff after continuous tests. It is unique .The best configuration of various alloying elements can combine the ball′s hardness and toughness’ at their best.

(3).Electric furnace smelting: All cast steel balls are produced by intermediate frequency electric furnace .The purity and stability of materials are effectively ensured after uniform temperatures conditioning and twice hot metal purificati0n.

(4).Assay before furnace :Temperature control is an important and complex process during cast steel ball production. Different tapping temperature and heat temperature are sensitively reflected in the quality of the products. It is requested to master the proper pouring temperature ,mold temperature ,so that can make sure the products achieve a good state of body tissue during the transition from Liquid to solid states.

(5).Mould forming: Pouring when the molten iron temperature difference between molten iron and the molds. In this way ,the ball can achieve internal organization of grain refinement and be more dense .Meanwhile ,the carbide is radically arranged ,and such Carbide is embedded in the matrix again during grinidng process, forming harde layer continuously .So that the hardness and thoughness is maintained to a reasonable.

(6).Heat treatment: We have two sets of heat treatment production line .One is oil quenching, the other is air quenching ,so that the grinding balls can be burring through quenching. And the grinding media has the characters of high hardness ,good thoughness,low wear rate ,low break rate, wear -resistant etc. through tempering

The Product Description of Superior Steel Forged Grinding Ball For Plant Cement and Mine

Model | Mechanical properties | Microstructure | |

HRC | Times of falling (5m) | ||

Low Chromium | ≥45 | 8000 | P+C |

Medium Chromium | ≥55 | 10000 | P+C |

High Chromium | ≥60 | 10000 | M+C |

Chemical Composition of Superior Steel Forged Grinding Ball For Plant Cement and Mine

Model | Chemical Composition | |||||

C | Si | Mn | Cr | P | S | |

Low Chromium | 2.3-3.4 | ≤1.5 | 0.7-1.5 | 1.3-2.7 | ≤0.1 | ≤0.1 |

Medium Chromium | 2.2-2.8 | 0.5-1.0 | 0.7-1.0 | 11.0-15.0 | ≤0.1 | ≤0.1 |

High Chromium | 2.4-3.2 | 0.5-0.8 | 0.7-1.2 | 15.0-18.0 | ≤0.1 | ≤0.1 |

- Q: our factory now produces steel castings in the use of polishing directly after spraying processing, but the powder sprayed 15But the spray powder touched off what is the reason we are not very strict requirements not only need to peel off bubbles can also, because our products are steel castings so we use steam hole sludge put on. Do not know if this spray treatment has no effect to thank friends with us!

- The pre treatment temperature and the quality of plastic powder are likely to be problems

- Q: Explain the heat treatment effect of casting parts, forging parts and welding parts

- 2 improve the crystal structure, enhance the formation and stability of spherical carbon crystal;Forgings are generally stress bearing members, and most of them are made of high strength medium carbon steel (alloy), which is formed by forging and fine crystalline. After the shell is annealed or quenched and tempered, the mechanical properties of the shell are more superior, and it has better strength and better elasticity;Welding materials.

- Q: What is the ejection angle of the die casting (Tan Gang)?

- Because after the wax, wax parts will have a slight contraction, which is good for demoulding. Many moulds don't do the ejection angle

- Q: Casting parts by shot blasting, spray painting, baking after the formation of very small rust spots, how to solve ah?

- The first process is very important. Shot blasting must be thorough. The solution is to wipe the surface of the paint with a release. Re shot

- Q: What is the casting material?

- Gray iron, carbon steel, low alloy steel, ductile iron, stainless steel, Aluminum Alloy can all be cast out

- Q: Cause of choking of casting parts

- Is it boiling from the picture? Does it sound like a fire? If not, it's not choking. I feel like choking. The gas doesn't drain out

- Q: What do you mean by "proofing" in the casting? Do you charge for the proofing?

- Proofing? In the casting industry is not called proofing, proofing is generally used in the printing industry, that is, according to the customer's drawings or samples, to do a first piece, to provide customers with the inspection process to meet their requirements;In the foundry industry, providing prototypes is sometimes difficult:1, customers if the provision of mold, it would be best, at this time, sample costs are very low, and almost the same as your regular products;2, the customer does not provide the mold, but in business relationships, your factory and not very sure must take this one, it requires your leadership decision-making, is free or low cost, or by a strict process offer (of course sample);3, not all of the casting process to provide samples are difficult, like lost foam can directly make a white NC prototype, and then assembled pouring, this is her unique advantages, first cost less than the opening process and so on;If you don't understand, you can continue to question me

- Q: Lathe processing stainless steel casting parts to use what type of tool, the speed into the amount of how much tool angle

- What kind of work, what kind of material, 204201304316, how big live ah? You ask?Can the 201 pieces of material and 304 of the pieces fit in a single car? Can I use the universal YG8 knife? Straight, knife, pipe thread?You should live to say, understand, say, do not understand, draw a simple drawing with Baidu doodle, marking the important size, this is good to answer ah!

- Q: How to solve casting defect casting?

- Different defects, different solutions, some shortcomings, the current domestic level can not be resolved

- Q: The difference between sheet metal and casting parts

- Casting parts are made by casting (followed by a variety of processing), the shape can be simple, can also be very complex, usually large parts, as a base, bed, work table, and so on, good seismic performance.

1. Manufacturer Overview

| Location | Anshan City, Liaoning Province,China |

| Year Established | 2002 |

| Annual Output Value | US$1 Million - US$2.5 Million |

| Main Markets | Domestic Market; South America; Eastern Asia; South Asia; Mid East |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai Port;Dalian Port;Tianjin Port;Yingkou Port |

| Export Percentage | |

| No.of Employees in Trade Department | 6 - 10 People |

| Language Spoken: | English; Chinese; Spanish |

| b) Factory Information | |

| Factory Size: | 24,400 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | grinding ball,grinding media,casting ball,casting grinding ball |

| Product Price Range | Average |

Send your message to us

Superior Steel Forged Grinding Ball For Plant Cement and Mine

- Loading Port:

- Shanghai Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords