Pre-stressed Hollow Core Purlin Making Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-stressed Hollow Core Purlin Making Machine

1. Structure of Pre-stressed Hollow Core Purlin Making Machine:

Pre-stressed Hollow Core Purlin Making Machine is our special developed products as results of our engineers research, with which 60%steel material will be saved compared with traditional revolving die method .Efficiency can be improved 3 to 5 times compared with conical die method, these machine are easy for operation and convenient for maintenance, products from these machines are in good quality, smooth appearance and accurate in size.

2. Main Features of Pre-stressed Hollow Core Purlin Making Machine:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

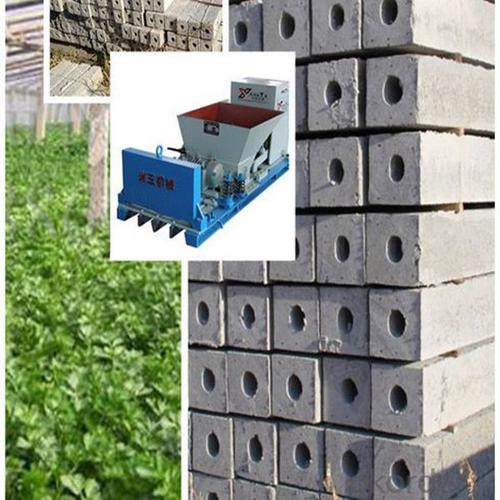

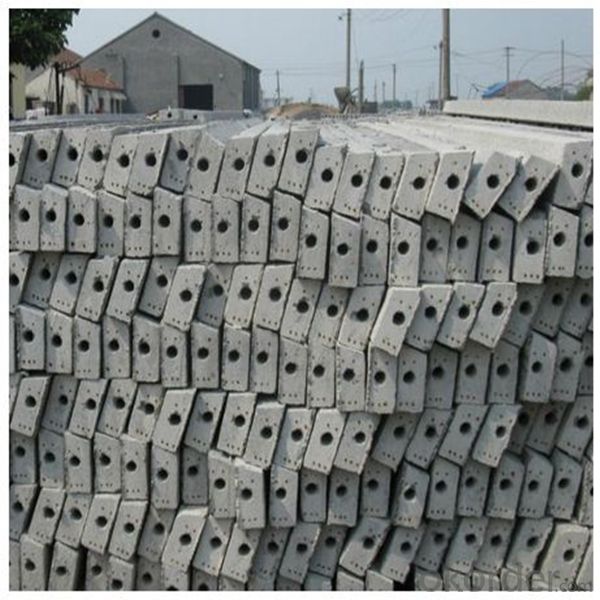

3. Pre-stressed Hollow Core Purlin Making Machine Images:

4. Pre-stressed Hollow Core Purlin Making Machine Specification:

Product name | Type | Productivity | Hole number |

Concrete purline machine | 60*120*140* | 1.3-1.5m/min | 4 |

Concrete purline machine | 60*130*150*4 | 1.3-1.5m/min | 4 |

Concrete purline machine | 60*140*160*4 | 1.3-1.5m/min | 4 |

Concrete purline machine | 70*150*170*2 | 1.3-1.5m/min | 2 |

Concrete purline machine | 80*160*180*2 | 1.3-1.5m/min | 2 |

Concrete purline machine | 60*110*130*4 | 1.3-1.5m/min | 4 |

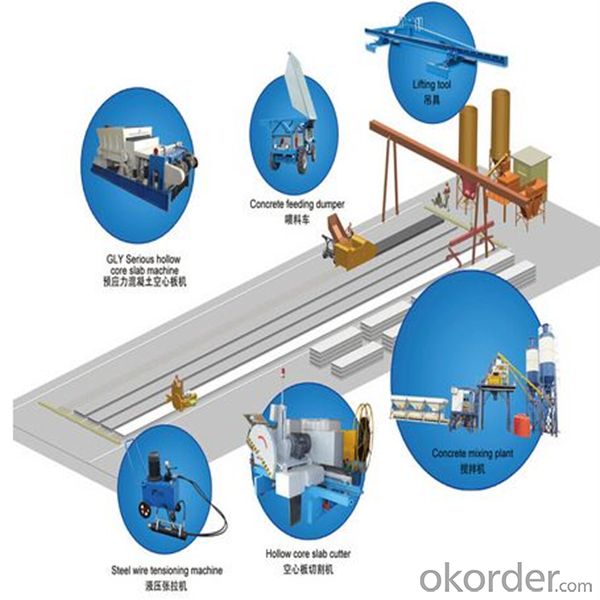

Production Line Layout

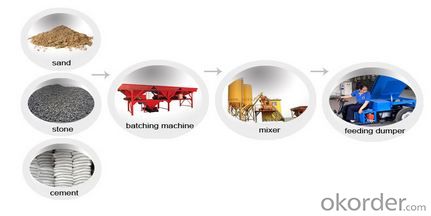

Production Process

Rebar tensioning

Raw materials preparing

Molding

Certificates

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. Customers from All Over The World

7. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• What kind of machine do you have?

Our main products: large span GLY concrete hollow core slab machine, light - weight wall panel machine, lintel machine, column machine, hollow core slab cutting machine, concrete feeding dumper, high-strength steel wire tensioning machine, which amount to more than the types and more than four hundred standards. We can provide the whole plan and technology supporting for concrete precast component.

8. Why choose us:

• 30 years manufacturing experience.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

- Q: How does operating machinery under water complicate mining procedures?

- Well it severely limits the type of power source you can use, corrosion of metal parts becomes a major factor, manipulation/positioning of machinery becomes extremely complicated, health and safety is even more of a problem, costs increase exponentially

- Q: I am need to sell some used machines and tools for parts. Anyone know of where I can post and auction/sell them online?That is not EBAY!

- Craigslist?

- Q: How to choose mechanical parts material ah?

- The performance of the various materials should be very familiar, and then consult the manual to see what general use in the area.

- Q: Remember before the 1980s?When we had shop classes in our schools?When we actually made products in America?When we supplied the world with steel, machine tools, and automobiles?Remember when we had a working middle class?

- Yes, before Bill Clinton signed NAFTA.

- Q: Why does the warning label on children's tylenol advise not to operate heavy machinery?

- It's a precautionary measure in-case some of the little Trolls on Y/A should get their hands on a bottle and try to drive you mad

- Q: would you be able to give reasons

- the general consensus is that the type of financing should match the lifespan of whatever you're buying. so for heavy machinery, these are typically long-term assets. as such, you want to use long-term debt (such as a long-term bank loan). ideally, the best financing is cash (you buy it outright). other alternatives would be to give the seller a corporate bond which promises them payments, etc. loan agreements are another option.

- Q: i've been working out on my arms for 6 months now but can't seem to get any results on the sides of my upper arms.i'm not really skinny,i'm avarage body build but i have skinny arms.i can grow muscle on front and back of my arms,but not on the sides.what are some good exercises,exercise machinery or techniques i can use to target these areas?(and sorry i don't know the technical names for these muscles in the arm)

- are you referring to triceps? If so, do chair dips. side leaning dumbell raise, laying side tri rise. These are crucial for bigger arms. Triceps. Just look up shoulders and arms from p90x. it'll help you.

- Q: What was the last thing that prevented you from driving or operating heavy machinery?

- Hi Cowbell, Simple!!! I don't know how to Drive Heavy Machinery..In Fact it Scares The Hell Out Of Me!!! Your Friend, poppy1

- Q: what is machinery?and its uses.?

- Machinery is a series of components working together to accomplish a particular task. They can be crude, simple machines such as a block and tackle or very complex like a CNC Machine or a monster earth moving crane. Most machinery is used in production or manufacturing.However machinery is als o used to move a ship through the water, dig a tunnel or mine shaft, drill for oil, make a baseball bat, make candy etc. The uses are endless.

- Q: Like only 90 or 120 degrees, but it's precisely controlled.Thanks!

- The steering on your car.

Send your message to us

Pre-stressed Hollow Core Purlin Making Machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords