Forming Machine for Prestressed Hollow Core Panel

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Forming Machine for Prestressed Hollow Core Panel

1. Structure of Forming Machine for Prestressed Hollow Core Panel:

Forming Machine for Prestressed Hollow Core Panel works on the long-line table, using the high-strength low-relaxation steel strand as the guide, using the pushing work method to forming the concrete hollow-core slab. The slab have the advantages of smooth surface, high-density structure, capable of making construction slabs of 4.2m to 18m. The GLY series concrete hollow-core slab mainly used on the larger bay workshop, school, hospital, shopping mall, office building, bulk storage plant etc.

2. Main Features of Forming Machine for Prestressed Hollow Core Panel:

• One machine can make one slab lower cost, high Wear-resistant, long service life.

• In case of quality problem the company provide free replacement.

• Provide technical support for free.

• Provide consumers with regular visits

• Simple structure, easy operate, less wear parts

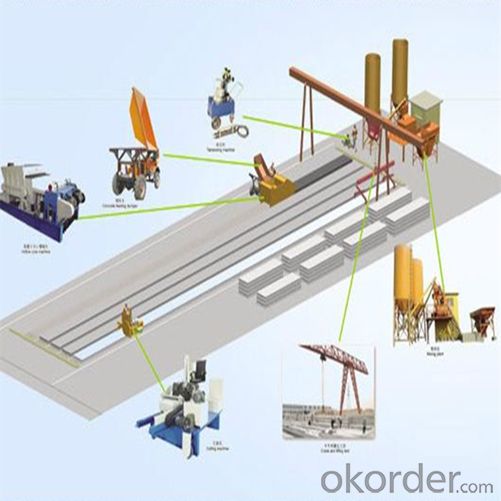

3. Forming Machine for Prestressed Hollow Core Panel Images:

4. Forming Machine for Prestressed Hollow Core Panel Specification:

Type | Aperture & diameter | Number and diameter of wires | Max span | Total power | Productivity (m/min) | Max. Load (KN/m2) | Overall dimension (mm) | Weight (kg) |

GLY180-1200 | 11/ peach | 12/9.5or12.7 | 9 | 18.5 | 1.1-1.3 | 16.16 | 2900X1500x1200 | 3300 |

GLY200-1200 | 8 /peach | 10/9.5or12.7 | 10 | 22 | 1.1-1.3 | 13.22 | 3700X1550X1550 | 5300 |

GLY250-1200 | 8/ peach | 10/12.7 | 12.6 | 33 | 1.1-1.3 | 11.1 | 3700X1550X1500 | 6200 |

GLY300-1200 | 6 /peach | 8/12.7 | 15 | 40 | 1.1-1.3 | 10.83 | 3700X1550X1500 | 6900 |

GLY380-1200 | 8 /rhomb | 8/12.7 | 18 | 39.2 | 0.8-1.0 | 12.27 | 4600X1850X1600 | 7500 |

Production Layout

5. Packing & Delivery

• Wire cables are used for fastening the machine on the trailer or inside the container.

• Machine covered with plastic film.

• Machines can be packed in tarpaulin or wooden case according to customer’s needs.

6. FAQ:

We have organized several common questions for our clients, may help you sincerely:

• What information we need to confirm with you before send a formal offer?

What kind of slab you want to make, wall panel, roof panel, lintel or something else?

Do you have exact slab size (slab thickness and width)? If not, please tell us the slab span, we will give you suggestion.

• Have you use this kind of machine before?

Our machine is totally different from European machine. Please don’t follow their instructions.

• How long can we receive the product after purchase?

In the purchase of product, within 20 working days we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 35 working days can be served.

7. Why choose us:

• 30 years manufacturing experience.

• Constitutor of the

• More than 10 patents.

• Passed ISO9001:2000 quality system certificate.

• More than 10 types of machine and over 100 models for choose.

• Supply complete set of technology and equipment solution.

• We can design and manufacture all kinds of concrete forming equipment according to customers' demands. Meanwhile we can even more provide our customers a complete set of technology and solution for all producing flow.

- Q: I'm specifically looking for training on heavy machinery such as bulldozers, backhoes cranes etc. The courses are given in montreal but there's a 10 year wait. If you know of any sort of training course of the sort in the 613 area code, please let me know. Thanks

- Try okorder /

- Q: Like Skynet from Terminator, there is a word they use besides quot;self aware.quot; A little help?

- Sentient?

- Q: can chimpanzees operate heavy machinery?

- Likely most any machinery can be adapted to allow most any primate or two year old human or computer to operate, but it would be unwise as occasionally good judgment is required and primates, and two year old humans and computers are quite unpredictable. Neil

- Q: maintenance for the 1st year is 150, and increases by 150 every year until the fourth year. if the interest is 85% per year find the equivalent uniform annual maintenance cost.

- Get a differnt credit card. 85% is way too high. . MWAP

- Q: where can i get the list sugar plant machinery with the details & market value?

- Ask Dole Pineapple or look on the US Dept Us Agriculture website or google

- Q: Presented here are selected transactions for Snow Company for 2012.Jan. 1Retired a piece of machinery that was purchased on January 1, 2002. The machine cost $66,300 on that date and had a useful life of 10 years with no salvage value.June 30Sold a computer that was purchased on January 1, 2009. The computer cost $31,200 and had a useful life of 5 years with no salvage value. The computer was sold for $12,480.Dec. 31Discarded a delivery truck that was purchased on January 1, 2007. The truck cost $53,000 and was depreciated based on an 8-year useful life with a $6,300 salvage value.Journalize all entries required on the above dates, including entries to update depreciation, where applicable, on assets disposed of. Snow Company uses straight-line depreciation. (Assume depreciation is up to date as of December 31, 2011.)

- Hey I am here for the first time. I found this question and I find the replies truly useful. I hope to offer something back to the community and assist others too.

- Q: I know the basics - clear cut the trees, put explosives in the mountains, blow the mountain up, separate coal from waste, fill up valleys and then plant some grass. What I want to know if more about the machinery used - some sites talk about a quot;dragline,quot; but don't have any more info than quot;it is used in MTRquot; What kind of explosives are used? How do they gather/separate the coal from the mining waste?

- Draglines okorder /

- Q: Gain on sales of machinery would be recorded as what? Debit or Credit?

- credit to the machinery account when sale done and debiting on purchase of machinery to the machinery account

- Q: I need it!!

- try okorder /

- Q: technical feasibility study for a theme parkabout machineriesand equipment

- How about what it will take a rollercoster that is fun and safe?

Send your message to us

Forming Machine for Prestressed Hollow Core Panel

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords