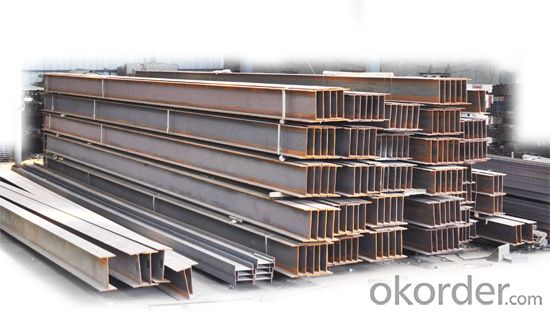

Steels Manufacture Building Material Construction on Hot Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Packaging & Delivery

Packaging Detail: | in bundles or as customer's requirement |

Delivery Detail: | Within 30days after receiving your deposit or copy of L/C |

2.Specifications

HRB400,HRB500 Steel Rebars

1.China direct supplier

2.Best service

3.Competitive price

4.Quantity assured

3.Product Description

Name | High Tensile Export Reinforcing Steel Bar ,Deformed Steel Bar ,HRB400B,HRB,46B,HRB500 Building Construction Material |

Standard | ASTM A615 /BS BS 4449 /GB HRB/ JIS G3112 |

Grade | A615 Gr40/60/75 BS 4449 Gr460,B500 GB HRB335,HRB400 ,HRB500

JIS G3112 SD390

|

Diameter | 6mm-40mm |

Length | 6-12m |

Technique | Low temperature hot-rolling reinforcing deformed steel rebar |

Tolerance | As the standard or as your requirement |

Application | Building, construction, road, bridge,etc |

Certificated | BV |

MOQ | 500tons per size steel rebar |

Packing details | Steel rebar packed in bundle or as your requirement |

Delivery | Within 30 days after deposit |

Payment | T/T or L/C |

4.Chemical Composition

Grade | Technical data of the original chemical composition (%) | |||||||

C | Mn | Si | S | P | V | |||

HRB400 | ≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | ||

Physics capability | ||||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation (%)

| ||||||

≥400 | ≥470 | ≥14 | ||||||

Grade | Technical data of the original chemical composition (%) | |||||||

C | Mn | Si | S | P | V | |||

HRB500 | ≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | ||

Physics capability | ||||||||

≥500 | ≥630 | ≥12 | ||||||

5. Theorectical weight

Diameter (MM) | Cross Sectional Area (MM2) | Theorectical Weight (KG/M) | Weight of 12M Bar (KG) | A Ton Contains 12M Bars (PCS) |

6 | 28.27 | 0.222 | 2.664 | 375.38 |

8 | 50.27 | 0.395 | 4.74 | 210.97 |

10 | 78.54 | 0.617 | 7.404 | 135.06 |

12 | 113.1 | 0.888 | 10.656 | 93.84 |

14 | 153.9 | 1.21 | 14.52 | 68.87 |

16 | 201.1 | 1.58 | 18.96 | 52.74 |

18 | 254.5 | 2 | 24 | 41.67 |

20 | 314.2 | 2.47 | 29.64 | 33.74 |

22 | 380.1 | 2.98 | 35.76 | 27.96 |

25 | 490.9 | 3.85 | 46.2 | 21.65 |

28 | 615.8 | 4.83 | 57.96 | 17.25 |

32 | 804.2 | 6.31 | 75.72 | 13.21 |

36 | 1018 | 7.99 | 98.88 | 10.43 |

40 | 1257 | 9.87 | 118.44 | 8.44 |

- Q: How are steel pipes used in the construction of wastewater treatment plants?

- Steel pipes are commonly used in the construction of wastewater treatment plants due to their durability, strength, and corrosion resistance. These pipes are used to transport wastewater from different points within the treatment plant, such as pipes for raw sewage, sludge, and treated water. Additionally, steel pipes are also used for structural purposes, such as supporting tanks and other equipment. Overall, steel pipes play a crucial role in the efficient and reliable operation of wastewater treatment plants.

- Q: What is the typical length of a steel pipe?

- The typical length of a steel pipe can vary depending on its purpose and application. However, standard lengths for steel pipes often range from 20 feet to 40 feet.

- Q: What are the different methods of coating steel pipes for insulation?

- Insulating steel pipes can be achieved through various methods, each with its own pros and cons. 1. One method involves applying a layer of thermal insulation material, like mineral wool or foam, onto the steel pipes. This helps minimize heat transfer and energy loss. While these coatings are easy to apply and offer excellent insulation properties, they are prone to degradation over time and require regular maintenance and replacement. 2. Another approach is to coat the steel pipes with materials that protect against corrosion, such as epoxy or polyethylene. These coatings act as a barrier, shielding the pipes from moisture, chemicals, and other corrosive elements. They are durable and long-lasting, providing effective protection. However, they may not offer significant thermal insulation. 3. Fusion-bonded epoxy (FBE) coating is a popular method that combines both insulation and corrosion protection. It involves applying a layer of epoxy powder to the pipes and heating it to create a strong bond. FBE coatings offer excellent adhesion, corrosion resistance, and some thermal insulation properties. They are commonly used in oil and gas pipelines, enduring harsh environments and high temperatures. 4. Polyurethane foam is often used as an insulation coating for steel pipes. It is applied by spraying or injecting the foam onto the pipe surface, where it expands and hardens, forming a protective layer. Polyurethane foam coatings provide exceptional thermal insulation and can be applied to pipes of different shapes and sizes. However, they require specialized equipment and expertise and may be susceptible to physical damage or moisture absorption if not properly sealed. 5. Ceramic coatings offer yet another option for insulating steel pipes. These coatings are typically applied through a thermal spray process, creating a layer of ceramic material on the pipe surface. Ceramic coatings provide insulation against high temperatures, corrosion resistance, and thermal shock protection. They are commonly used in industries like power generation and aerospace, where extreme temperature conditions are present. However, ceramic coatings can be costly and require specialized equipment and expertise for application.

- Q: How are steel pipes used in power plants?

- Power plants rely heavily on the extensive use of steel pipes for a variety of purposes. When it comes to transporting fluids and gases, steel pipes are the go-to choice. They effectively carry water, steam, and fuel (like oil or gas) throughout the power plant. The reason steel pipes are so widely used for this purpose is because of their exceptional strength and durability. They can withstand the high pressures and temperatures found in power plants without faltering. Another crucial role steel pipes play in power plants is in the boilers. They are an integral part of the boiler system, responsible for the transportation of hot gases and steam. These pipes are specifically designed to endure extreme heat and pressure, ensuring the safe and efficient operation of the boiler. Moreover, steel pipes are utilized in the cooling systems of power plants. They facilitate the circulation of water to cool down essential equipment such as turbines and condensers. These pipes are built to withstand corrosion caused by the cooling water, all while maintaining the required flow rate and pressure. Additionally, steel pipes find their place in the construction of power plant structures. They are extensively used for fabricating support structures like frames, platforms, and walkways. Steel pipes possess excellent structural integrity and can bear heavy loads, making them the perfect choice for these applications. In conclusion, steel pipes fulfill a crucial role in power plants by efficiently transporting fluids and gases, serving as an essential component of the boiler system, facilitating cooling processes, and providing structural support. Their strength, durability, and resistance to extreme conditions make them indispensable in the operation of power plants.

- Q: What is the role of steel pipes in sewage systems?

- The role of steel pipes in sewage systems is to provide a durable and reliable means of transporting wastewater and sewage from homes, businesses, and other sources to treatment plants or disposal sites. Steel pipes are known for their strength, corrosion resistance, and longevity, making them suitable for withstanding the harsh and corrosive nature of sewage. They are capable of handling high-pressure flows and can withstand the weight and pressure of the surrounding soil. Additionally, steel pipes are often used in larger diameter applications due to their ability to carry larger volumes of sewage efficiently.

- Q: How are steel pipes used in the manufacturing of boilers?

- Steel pipes are an integral component in the manufacturing of boilers due to their strength, durability, and heat-resistant properties. Boilers are used to generate steam or heat water for various industrial and commercial applications. Steel pipes are primarily used in the construction of boiler tubes, which serve as the main heat transfer medium. These tubes are subjected to high temperatures and pressure, making it crucial to use a material that can withstand these extreme conditions. Steel, with its excellent mechanical properties and resistance to corrosion, is the ideal material for this purpose. The manufacturing process of boilers involves forming the steel pipes into specific shapes and sizes to create the boiler tubes. These tubes are then connected to form a network of channels through which hot gases or water flow. The steel pipes used in this process are often seamless or welded, depending on the requirements of the boiler design. The steel pipes used in boilers must meet stringent quality standards to ensure the safety and efficiency of the system. They are tested for their ability to withstand high pressure, temperature, and corrosion. Additionally, they undergo various inspections and tests, such as ultrasonic testing and radiographic examination, to detect any defects or flaws that could compromise the boiler's performance. In summary, steel pipes play a crucial role in the manufacturing of boilers by serving as the primary material for boiler tubes. Their strength, durability, and heat-resistant properties make them suitable for withstanding high temperatures and pressure. These pipes undergo rigorous testing to ensure their quality and reliability in creating efficient and safe boiler systems.

- Q: What are the factors affecting the pressure rating of steel pipes?

- The factors affecting the pressure rating of steel pipes include the material of the pipe, its thickness, diameter, and quality, as well as the temperature and type of fluid being transported. Additionally, the operating conditions, such as the level of stress or strain on the pipe, also play a significant role in determining its pressure rating.

- Q: How are steel pipes protected against fire?

- Steel pipes are typically protected against fire through the application of fire-resistant coatings or by encasing them in fire-rated materials, such as concrete or gypsum board. Additionally, fire sprinkler systems or fire-resistant insulation may be installed around the pipes to provide an added layer of protection.

- Q: 45 and 316 which steel tubes are of high hardness?

- 316 stainless steel by adding Mo element, the corrosion resistance, and high temperature strength has greatly improved, high temperature can reach 1200-1300 degrees, can be used in severe conditions. 316F stainless steel is easy to cut stainless steel with high sulfur content. Good corrosion resistance, easy processing, good smoothness, suitable for axial parts.

- Q: Can stainless steel pipes spray black paint?

- Can. The surface roughening with a thick gauze, do not use ordinary paint intensity difference. With resin paint, paint can be

Send your message to us

Steels Manufacture Building Material Construction on Hot Sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords