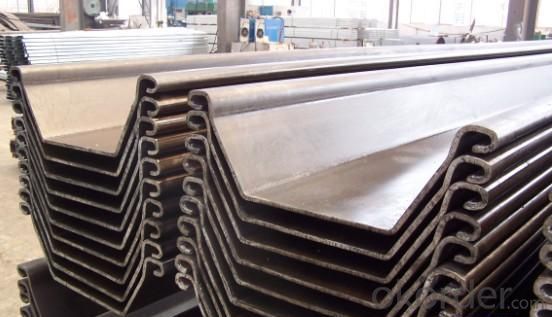

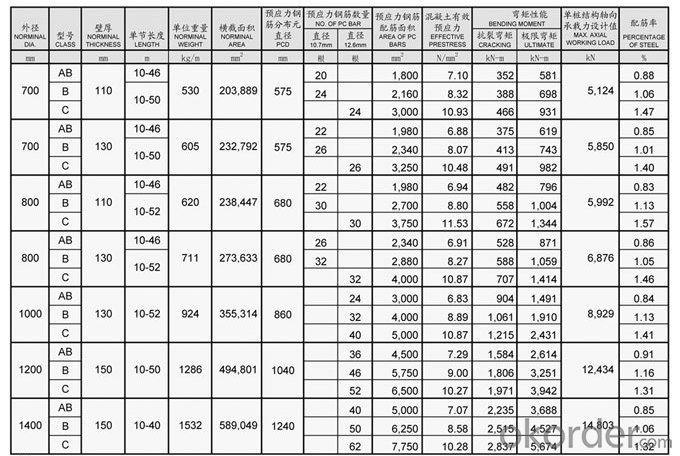

Steel Tubular Pile 1400mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: What are the properties of weathering steel for outdoor sculptures?

- Weathering steel, also known as Corten steel, is widely used for outdoor sculptures due to its unique properties. It is highly resistant to corrosion, making it ideal for withstanding outdoor elements without the need for additional protective coatings. Weathering steel forms a protective rust-like layer on its surface, which not only enhances its aesthetic appeal but also acts as a barrier against further corrosion. This self-protecting quality makes it a durable and low-maintenance material for outdoor sculptures. Additionally, weathering steel has a high tensile strength, allowing for the creation of intricate and large-scale sculptures.

- Q: What are the different types of steel chains and their applications?

- There are several types of steel chains, each designed for specific applications. Some common types include: 1. Grade 30 chains: These chains are general-purpose chains commonly used in applications such as towing, logging, and agriculture. 2. Grade 43 chains: Also known as high-test chains, they have a higher tensile strength and are ideal for heavy-duty applications like load securement and transportation. 3. Grade 70 chains: These chains are specifically designed for transportation and tie-down applications. They have a high strength-to-weight ratio, making them suitable for securing heavy cargo. 4. Grade 80 and Grade 100 chains: These chains are extremely strong and commonly used in lifting and rigging applications. They are capable of withstanding heavy loads and are often used in construction and industrial settings. 5. Stainless steel chains: These chains are corrosion-resistant and ideal for applications where exposure to moisture or chemicals is a concern. They are commonly used in marine environments, food processing, and medical equipment. Each type of steel chain has its own unique properties and applications, so it is essential to choose the appropriate chain based on the specific demands of the task at hand.

- Q: How is steel used in the production of electrical transformers?

- Steel is used in the production of electrical transformers as the core material due to its magnetic properties. The laminated steel core provides a low reluctance path for the magnetic field, allowing efficient transfer of electrical energy and reducing losses.

- Q: What are the different types of steel coatings and finishes available for steel products?

- There are several types of steel coatings and finishes available for steel products. Some common options include galvanized coatings, which provide corrosion resistance through a layer of zinc; powder coatings, which are applied as a dry powder and then cured to form a durable finish; and paint coatings, which can be applied in various colors and provide both protection and aesthetic appeal. Additionally, there are specialty coatings such as chrome plating, nickel plating, and epoxy coatings, each offering unique properties and benefits for specific applications.

- Q: What are the different types of steel products used in the manufacturing of medical equipment?

- There are several types of steel products used in the manufacturing of medical equipment, including stainless steel, carbon steel, and alloy steel. Stainless steel is commonly used due to its corrosion resistance and ability to withstand sterilization processes. Carbon steel is often used for structural components, while alloy steel is utilized for its strength and durability in specialized applications.

- Q: What are the different types of steel grilles and screens available?

- There are several different types of steel grilles and screens available, including welded steel grilles, expanded metal grilles, perforated metal grilles, and woven wire mesh screens. Each type offers unique features and benefits, making them suitable for various applications such as security, ventilation, and filtration.

- Q: What are the different types of steel fasteners and their applications?

- There are several types of steel fasteners commonly used in various applications. Some of the most popular ones include screws, bolts, nuts, and washers. Screws are versatile and can be used in woodworking, metalworking, and general construction. Bolts are often used for heavy-duty applications, such as in machinery or structural installations. Nuts are paired with bolts to secure objects together, while washers provide a smooth surface and distribute pressure. Additionally, there are specialized fasteners like rivets and anchors that serve specific purposes in industries like aerospace and construction.

- Q: How are steel products used in the manufacturing of machinery?

- Steel products are commonly used in the manufacturing of machinery due to their strength, durability, and versatility. They are used to create various components such as frames, gears, shafts, and bearings, which are crucial for the functionality and structural integrity of machinery. Steel's high tensile strength makes it ideal for handling heavy loads and withstanding intense forces, ensuring the machinery can operate efficiently and safely. Additionally, steel's ability to be easily shaped and formed allows for complex designs and precise manufacturing, further enhancing the performance and reliability of machinery.

- Q: What are the applications of stainless steel in the food industry?

- Stainless steel has numerous applications in the food industry due to its unique properties. It is commonly used in food processing, storage, and equipment manufacturing. Its corrosion resistance makes it ideal for food contact surfaces, ensuring hygiene and preventing contamination. Stainless steel is used in the production of utensils, sinks, countertops, and appliances due to its durability, easy cleaning, and resistance to heat and chemicals. It is also used in food transportation, such as tanks and containers, as it maintains the quality and integrity of the food during transit.

- Q: What are the different types of steel coatings?

- There are various types of steel coatings, including galvanized coatings, epoxy coatings, powder coatings, and organic coatings.

Send your message to us

Steel Tubular Pile 1400mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords