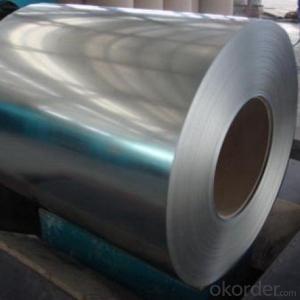

Steel Stainless 316 NO.1 Finish,Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 25 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description for Stainless Steel Coils/Sheets:

Name: stainless steel coils/plates/sheets

Discharge Port: Any Port, China

Cold Rolled Size: Thickness0.3-8mm,Width:280-2100mm

Hot Rolled Size: Thickness3-14mm,Width:650-2100mm

Hot Rolled/Cold Rolled Plates : Thickness2-80mm,Width:1500-3000mm

Coil Weight: About 20 Tons

Grade: 201,202,304/304L/304H, 316/316L/316H, 409/L,430 etc.

Technique: Hot Rolled/Cold Rolled

Finish:2B, BA, 2D, No1, No2 etc

Edge: Mill Edge / Slitting Edge

Packaging: In bundles, or as customer's requirement

Place of Origin: Made in China

MOQ: 20 Tons

Payment Terms: 100% LC at sight, or 100%TT in advance

Delivery Time: With 30-40 days after deposit

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

Details for the products:

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail | Standard export packing or following customer's demand |

Delivery Time | Within 30-40 days after deposit or according to the order quantity |

FAQ for Stainless Steel Coils/Sheets:

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

FAQ for Stainless Steel Coils/Sheets:

Q: How long is the delivery time?

A: Normally 30-40 days, but mostly according to the specific requirements or the quantity

Q: Could you send me sample?

A: We can supply you with the sample for free, but the delivery charges will be covered by customers.

FAQ for Stainless Steel Coils/Sheets:

Q: How can I get the samples?

A: If you need some samples to test ,please pay for the transportation freight of samples and our samples are free for you.

Q: How can I get your price list?

A: Please send us your email or fax and order information – Quantity, Specification (steel type, thickness, width, surface finish), then I can send you the price list.

- Q: What are the different types of stainless steel sheet finishes for decorative purposes?

- For decorative purposes, there are several different types of finishes commonly used on stainless steel sheets. These finishes are achieved through various surface treatments and processes, resulting in distinct appearances and textures. Some of the popular finishes include: 1. Brushed or satin finish (No. 4 finish): It is achieved by applying abrasive belts to the surface, creating a smooth, satin-like appearance. This finish is commonly used in architecture and decoration. 2. Mirror finish (No. 8 finish): The surface is polished to a highly reflective mirror-like appearance. It is often used in applications where aesthetics are important, such as wall cladding and decorative elements. 3. Hairline finish: The surface is polished with fine abrasive belts, creating a fine, directional grain pattern. It provides a subtle and elegant look, commonly used in interior design applications. 4. Embossed finish: The stainless steel sheet is pressed with a pattern or texture, creating a three-dimensional surface. This finish is often used in architectural applications, such as wall panels and decorative trim. 5. Bead blasted finish: The surface is blasted with fine glass beads under high pressure, resulting in a uniform, matte appearance. It provides a unique texture and is commonly used in applications where a non-reflective surface is desired. 6. Colored finishes: Stainless steel sheets can also be coated with various colors through processes like PVD or powder coating. These finishes offer a wide range of color options, allowing for more design flexibility. Overall, the choice of stainless steel sheet finish for decorative purposes depends on the desired aesthetic, functionality, and application requirements. Each finish offers its own unique look and feel, providing versatile design possibilities in different industries.

- Q: Can stainless steel sheets be used for mezzanine flooring?

- Yes, stainless steel sheets can be used for mezzanine flooring. Stainless steel is a durable and corrosion-resistant material, making it suitable for high traffic areas like mezzanine floors. It offers strength and stability, making it a popular choice for industrial and commercial applications.

- Q: What are the different methods of cutting stainless steel sheets?

- Depending on specific requirements and desired precision, there are several methods available for cutting stainless steel sheets. One commonly used method is shearing, which involves utilizing a machine with sharp blades to cut through the material. Shearing is ideal for straight cuts and offers a relatively fast and cost-effective solution. For high precision and intricate designs, laser cutting is a highly recommended method. It utilizes a powerful laser beam to provide a clean and smooth cut. This method is widely used in industries that prioritize precision and quality finishes. Plasma cutting, on the other hand, utilizes a high-temperature plasma arc to melt through stainless steel sheets. It is particularly suitable for cutting thick sheets or materials with high conductivity. This method offers fast cutting speeds and can handle various shapes and thicknesses. Waterjet cutting is a versatile method that involves using a high-pressure jet of water mixed with abrasive particles to cut through stainless steel sheets. It offers high precision and can create complex shapes. Additionally, waterjet cutting is a cold process, meaning it does not produce heat-affected zones or alter the material's structure. In situations where other methods are not feasible, abrasive cutting can be used. This method involves using an abrasive wheel or disc to grind and cut through stainless steel sheets. It can be done manually or with the assistance of power tools, such as angle grinders. The choice of cutting method depends on various factors, including the thickness of the stainless steel sheet, desired precision, budget, and production requirements. Each method has its own advantages and limitations, allowing for flexibility in choosing the most suitable option.

- Q: Can stainless steel sheets be used for wall paneling?

- Yes, stainless steel sheets can be used for wall paneling. They are durable, resistant to corrosion, and provide a sleek and modern aesthetic to any space. They are commonly used in kitchens, bathrooms, and commercial settings as they are easy to clean and maintain.

- Q: Can stainless steel sheets be etched with designs?

- Yes, stainless steel sheets can be etched with designs. Stainless steel is a versatile material that can be etched using various methods such as chemical etching or laser engraving. Chemical etching involves applying a corrosive substance to the surface of the stainless steel, which selectively removes the unprotected areas and leaves the design etched onto the sheet. Laser engraving, on the other hand, uses a high-powered laser beam to etch the design onto the stainless steel surface. Both methods can achieve intricate and detailed designs on stainless steel sheets, making it a popular choice for decorative and functional applications in various industries.

- Q: Can stainless steel sheets be used for kitchen appliances?

- Yes, stainless steel sheets can be used for kitchen appliances. Stainless steel is a popular choice for kitchen appliances due to its durability, resistance to corrosion, and sleek appearance. It is commonly used for refrigerators, ovens, dishwashers, and other kitchen appliances.

- Q: Can stainless steel sheets be used for water pipelines?

- Yes, stainless steel sheets can be used for water pipelines. Stainless steel is highly resistant to corrosion and has excellent strength, making it a suitable material for water pipelines that require durability and longevity. Additionally, stainless steel's smooth surface helps to maintain water flow efficiency and prevent contamination.

- Q: What's the difference between cold rolling and hot rolling of stainless steel plate?

- Cold rolling and hot rolling are different processes, and cold rolling is usually made by longitudinal rolling. Cold rolling process usually includes preparation of raw materials, pickling, rolling, degreasing, annealing (heat treatment), finishing and so on. Cold rolling takes hot rolling product as raw material, and the raw material should be removed before cold rolling so as to ensure the surface cleanness of cold rolling products.

- Q: Can stainless steel sheets be used for architectural canopies?

- Yes, stainless steel sheets can be used for architectural canopies. Stainless steel is a versatile material that offers several benefits in architectural applications, including canopies. Firstly, stainless steel is highly durable and resistant to corrosion, making it suitable for outdoor installations. This ensures that the canopy will withstand harsh weather conditions and maintain its appearance over time. Additionally, stainless steel has a sleek and modern aesthetic that can enhance the overall design of the canopy. It can be polished to a mirror-like finish or brushed to create a unique texture, providing architects with various options to achieve their desired look. Stainless steel sheets are also available in different thicknesses, allowing for customization based on the specific requirements of the canopy. This flexibility ensures that the material can support the weight of the structure and any additional elements, such as lighting or signage. Moreover, stainless steel is a sustainable choice for architectural canopies as it is fully recyclable. This aligns with the growing demand for environmentally-friendly construction materials and practices. In summary, stainless steel sheets are a suitable and popular choice for architectural canopies due to their durability, aesthetic appeal, flexibility, and sustainability.

- Q: Can stainless steel sheets be used for water filtration systems?

- Yes, stainless steel sheets can be used for water filtration systems. Stainless steel is commonly used in water filtration due to its excellent corrosion resistance and durability. It is able to withstand high pressure, temperature variations, and exposure to different chemicals, making it suitable for long-term use in water filtration applications. The smooth surface of stainless steel sheets also facilitates easy cleaning and prevents the accumulation of bacteria and other contaminants. Additionally, stainless steel is a non-reactive material, meaning it does not release any harmful substances into the filtered water, ensuring its safety for consumption. Overall, stainless steel sheets are a reliable and effective choice for water filtration systems.

Send your message to us

Steel Stainless 316 NO.1 Finish,Good Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 25 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords