Steel Rebar with Hight Quality for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Specifications of Steel Rebar with Hight Quality for Construction:

Standard | GB UK USA | HRB335 HRB400 HRB500 G460B, B500A, B500B,B500C GR40, GR60 | |

Diameter | 6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm, 22mm,25mm,28mm,32mm,36mm,40mm,50mm | ||

Length | 6M, 9M,12M or as required | ||

Price | Keep lower operating costs so as to offer competitive price for our clients | ||

Delivery Detail | within 45 days after received advanced payment or LC. | ||

Application | mainly used in construction industry to reinforce concrete structures and so on | ||

Invoicing | Actual or Theoretical Weight Basis as buyer’s request. | ||

Type | Hot rolled steel rebar | ||

Brand name | DRAGON | ||

Theoretical weight and section area of each diameter as below for your information:

Diameter(mm) | Section area (mm²) | Mass(kg/m) | Weight of 12m (kg) | Pcs/ton |

6 | 28.27 | 0.222 | 2.664 | 375.38 |

8 | 50.27 | 0.395 | 4.74 | 210.97 |

10 | 78.54 | 0.617 | 7.404 | 135.06 |

12 | 113.1 | 0.888 | 10.656 | 93.84 |

14 | 153.9 | 1.21 | 14.52 | 68.87 |

16 | 201.1 | 1.58 | 18.96 | 52.74 |

18 | 254.5 | 2.00 | 24 | 41.67 |

20 | 314.2 | 2.47 | 29.64 | 33.74 |

22 | 380.1 | 2.98 | 35.76 | 27.96 |

25 | 490.9 | 3.85 | 46.2 | 21.65 |

28 | 615.8 | 4.83 | 57.96 | 17.25 |

32 | 804.2 | 6.31 | 75.72 | 13.21 |

36 | 1018 | 7.99 | 98.88 | 10.43 |

40 | 1257 | 9.87 | 118.44 | 8.44 |

50 | 1964 | 15.42 | 185.04 | 5.40 |

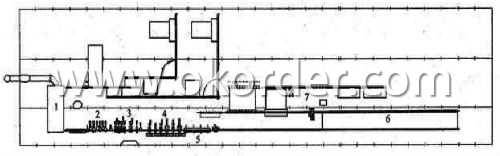

The production process of Steel Rebar with Hight Quality for Construction:

1-Waling beam furnace 2-Roughing rolling group 3-Intermediate rolling train

4-Finishing rolling group 5-Water-cooling device 6-Walking beam cooler

7-Finishing equipment(including the cold scale shear,short feet collection system,

automatic counting device,bundling machine, collect bench)

Usage and Applications of Steel Rebar with Hight Quality for Construction:

Deformed bar is widely used in buildings, bridges, roads and other engineering construction. Big to highways, railways, bridges, culverts, tunnels, public facilities such as flood control, dam, small to housing construction, beam, column, wall and the foundation of the plate, deformed bar is an integral structure material. With the development of world economy and the vigorous development of infrastructure construction, real estate, the demand for deformed bar will be larger and larger..

Packaging & Delivery of Steel Rebar with Hight Quality for Construction:

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Each bundle weight: 2-3MT, or as required

Payment terms: TT payment in advance or Irrevocable LC at sight.

Trade terms :FOB, CFR, CIF

Label:to be specified by customer, generally, each bundle has 1-2 labels

Steel Rebar in stock

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: What makes stainless steel stainless?

A: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q3: Can stainless steel rust?

A3: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images

- Q: How is steel wire rod processed to achieve desired properties?

- Steel wire rod is processed through a series of steps to achieve the desired properties. The first step is the melting of raw materials such as iron ore, coal, and limestone in a blast furnace. This process removes impurities and produces molten iron. The molten iron is then converted into steel through the basic oxygen furnace (BOF) or electric arc furnace (EAF) process. In the BOF process, oxygen is blown into the molten iron to remove carbon and other impurities, while in the EAF process, an electric arc is used to melt scrap steel. Once the steel is produced, it is cast into billets or blooms, which are semi-finished forms of steel. These billets or blooms are then hot rolled to reduce their size and shape them into wire rod form. Hot rolling involves passing the steel through a series of rollers that apply pressure and heat to shape the material. After hot rolling, the wire rod is cooled and then undergoes a process called pickling, where it is immersed in an acid solution to remove scale and impurities from the surface. This step helps improve the surface quality of the wire rod. Next, the wire rod is cold drawn through a series of dies to reduce its diameter and increase its strength. Cold drawing involves pulling the wire rod through progressively smaller dies, which elongates and work-hardens the material. To achieve the desired properties, the wire rod may undergo additional processes such as heat treatment. Heat treatment involves heating the wire rod to a specific temperature and then cooling it rapidly or slowly to modify its microstructure and improve its mechanical properties. Finally, the wire rod is typically coated with a protective layer or surface treatment to enhance its corrosion resistance and improve its surface finish. Common coatings include zinc, phosphate, or polymer coatings. Overall, the processing of steel wire rod involves a combination of melting, casting, rolling, pickling, cold drawing, heat treatment, and coating processes to achieve the desired properties such as strength, ductility, surface finish, and corrosion resistance.

- Q: How is steel wire rod used in the manufacturing of wire for electrical applications?

- Steel wire rod is used in the manufacturing of wire for electrical applications as it serves as the raw material for producing electrical wires. The steel wire rod is processed through various stages, such as drawing, annealing, and coating, to transform it into a high-quality and reliable wire that can conduct electricity effectively. This wire is then utilized in the production of electrical cables, wiring harnesses, and other electrical components, enabling the transmission of electricity in a safe and efficient manner.

- Q: How is steel wire rod used in the manufacturing of wire forms for wind turbines?

- Steel wire rod is an essential component in the manufacturing process of wire forms for wind turbines. It serves as the raw material that undergoes various processes to transform it into the final wire forms used in wind turbine applications. Firstly, steel wire rod is selected for its high strength and durability, as it needs to withstand the harsh environmental conditions and high loads experienced by wind turbines. The wire rod is typically made of low carbon steel, which offers the desired combination of strength and flexibility. The manufacturing process begins with the wire rod being fed into a wire drawing machine. This machine pulls the wire rod through a series of dies, gradually reducing its diameter and increasing its length. This process is known as wire drawing and helps to improve the wire's mechanical properties, including its tensile strength and surface finish. Once the wire has been drawn to the desired diameter, it is ready for further processing. It may undergo additional treatments such as heat treatment or surface coating to enhance its properties. Heat treatment can provide improved strength and flexibility, while surface coating can protect against corrosion and abrasion. After the necessary treatments, the wire is then formed into the desired shape for wind turbine components. This can be done through various methods such as bending, twisting, or welding. These forming processes are crucial in creating wire forms that can effectively support and transmit the mechanical loads experienced by wind turbines. The wire forms manufactured from steel wire rod are used in various applications within wind turbines. They can be used as support structures for the blades, providing stability and strength. Additionally, wire forms are used as electrical conductors, transmitting power generated by the wind turbine to the electrical grid. In conclusion, steel wire rod plays a vital role in the manufacturing of wire forms for wind turbines. Its high strength, durability, and versatility make it an ideal material for withstanding the demanding conditions and loads experienced by wind turbines. Through various processes, the wire rod is transformed into wire forms that serve as crucial components in wind turbine construction and operation.

- Q: How is steel wire rod used in the manufacturing of wire rope turnbuckles?

- Steel wire rod is used in the manufacturing of wire rope turnbuckles as the primary material for creating the wire ropes. The wire rod is first drawn and shaped into individual wires, which are then twisted and braided together to form strong and durable wire ropes. These wire ropes are then incorporated into the construction of turnbuckles, providing the necessary tensile strength and flexibility for adjusting and securing loads in various applications.

- Q: How is steel wire rod used in the manufacturing of wire baskets for industrial applications?

- Steel wire rod is a primary material used in the manufacturing of wire baskets for industrial applications. It serves as the base material that is shaped, bent, and welded to create the framework of the basket. The high tensile strength and durability of steel wire rod make it ideal for withstanding heavy loads and rough handling in industrial environments. Additionally, the steel wire rod can be coated or galvanized to enhance corrosion resistance, ensuring longevity and reliable performance of the wire baskets.

- Q: How is steel wire rod used in the manufacturing of wire for high-speed trains?

- The manufacturing of wire for high-speed trains relies heavily on steel wire rod. This component is carefully chosen for its strength and durability, as it must withstand the intense forces and stresses experienced during train operation. Typically made from high-grade steel alloys, the selected wire rod ensures the wire's reliability. Once selected, the steel wire rod undergoes a series of manufacturing steps. It is heated to a specific temperature and then passed through a rolling mill to reduce its diameter and elongate it. This process improves the wire's mechanical properties, resulting in a thinner and longer wire. After rolling, the wire undergoes further treatment to enhance its strength and flexibility. Heat treatment methods like quenching and tempering are applied to achieve the desired characteristics. These treatments increase the wire's hardness, tensile strength, and resistance to fatigue, making it suitable for high-speed train applications. To protect the wire from corrosion and improve its electrical conductivity, it undergoes surface treatments and coatings. These treatments ensure the wire's longevity and maintain its performance in demanding operating environments. Once the wire is cut to specified lengths, it is spooled for transportation to train manufacturers. At the manufacturing facility, the wire is used in various applications such as electrical systems, signaling, traction control, and suspension components. Its role is crucial in transmitting electrical signals, providing stability, and supporting the overall structure of the high-speed train. In conclusion, steel wire rod plays a vital role in the manufacturing of wire for high-speed trains. Through a series of processes, it is transformed into a strong, durable, and reliable wire that meets the stringent requirements of high-speed train operations.

- Q: What are the main factors influencing the choice of steel wire rod order packaging marking options?

- The main factors influencing the choice of steel wire rod order packaging marking options include the specific requirements and regulations of the industry, the destination and transportation method of the order, the need for traceability and quality control, and any customer-specific preferences or branding requirements.

- Q: How is the ductility of steel wire rod determined?

- Various mechanical tests and measurements determine the ductility of steel wire rod. The tensile test is a commonly used method for evaluating ductility. During this test, a sample of the steel wire rod is pulled until it fractures, and the amount of deformation it undergoes before breaking is measured. Throughout the tensile test, the steel wire rod experiences an increasing load or force, while its elongation or deformation is continuously measured. The force needed to stretch the wire to a specific length is recorded, and a stress-strain curve is created. The stress-strain curve provides information about the ductility of the steel wire rod. The elongation or deformation at the point of fracture is a crucial parameter for assessing its ductility. A higher elongation indicates greater ductility because it means the material can withstand more deformation before breaking. In addition to the tensile test, other tests like the bend test and impact test can also evaluate the ductility of steel wire rod. During the bend test, the wire is bent to a specific angle without fracturing. The ability to bend without breaking shows good ductility. Similarly, the impact test measures the energy absorbed by the wire when it experiences a sudden impact. Higher energy absorption suggests better ductility because it means the material can absorb and distribute the impact forces without fracturing. In conclusion, the ductility of steel wire rod is determined through mechanical tests like the tensile test, bend test, and impact test. These tests assess the wire's deformation capabilities, its ability to bend without breaking, and its energy absorption during impact, respectively.

- Q: How is steel wire rod used in the production of wire mesh for concrete reinforcement?

- Steel wire rod is used in the production of wire mesh for concrete reinforcement by being drawn through a series of dies to reduce its diameter and increase its length. This process, known as wire drawing, creates a strong and uniform wire that is then woven or welded into mesh sheets. The wire mesh is then placed within the concrete mixture to provide additional strength, prevent cracking, and enhance the overall structural integrity of the concrete.

- Q: How is steel wire rod recycled or disposed of?

- There are multiple ways to handle steel wire rod, either by recycling or disposing of it. Melting and reusing it in the production of new steel products is a common method of recycling. This process entails collecting the wire rod from different sources like construction sites, manufacturing facilities, or recycling centers, and then melting it in a furnace. Once melted, impurities and contaminants are eliminated, and the molten steel is molded into new wire rods or other steel products. Another recycling method involves mechanical processing. The wire rod is shredded into smaller pieces, which can then serve as raw material for manufacturing new steel products. These shredded pieces can be used for producing rebar, wire mesh, or other steel-based items. Moreover, steel wire rod can be disposed of responsibly in an environmentally-friendly way. If it is contaminated with hazardous substances or cannot be recycled due to its condition, it may be necessary to dispose of it in a landfill or designated waste management facility. However, it is crucial to emphasize that this disposal method should only be utilized as a last resort, as recycling is a more sustainable and environmentally conscious option. Overall, the recycling and disposal of steel wire rod involve various techniques, with recycling being the preferred choice due to its economic and environmental advantages. Recycling steel wire rod helps conserve valuable resources, save energy, and reduce the overall carbon footprint.

Send your message to us

Steel Rebar with Hight Quality for Construction

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords