Steel prices cold rolled china express Alibaba

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 58357 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Cold Rolled Steel coil is a mill product made with a high degree of gauge accuracy and uniformity of physical characteristics.

The smooth deoxidized matte finish gives an excellent base for paint, lacquer and enamel. Box annealing and absence of

scale permit stamping and moderate drawing operations. Sheets bend flat on themselves without cracking. Oiling protects

Surface against rust. The application of surface oil to cold rolled steel coil/sheet is intended to provide protection from corrosion

("rusting") during shipment and warehousing.

These cold rolled steel coil/sheet grades have excellent formability, which facilitates cold forming operations, and are ideal

for deep drawing. Our range of steels for cold forming offer excellent forming performance, due to the low scattering of their

chemical composition and their mechanical properties, which guarantees processing consistency.

Standard and Grade :

Cold rolled steel coils | ||||

JIS G3141-2005 | EN10130-2006 | ASTM A1008-12a | ||

Commercial quality | SPCC | DC01 | CS Type A/B/C | |

Drawing quality | SPCD | DC03 | DS Type A/B | |

Deep drawing quality | SPCE SPCF(non aging) | DC04 | DDS | |

Extra deep drawing quality | SPCG(non aging) | DC05/06 | EDDS | |

Application :

Automobile Industry, White Goods, Home Applicances, Oil & Air filters, semi product for coating with enamel or zinc, construction &

building sector, air-conditioning, furniture, radiators, tubes, profiles, mechanical construction, shelving, containers, drums

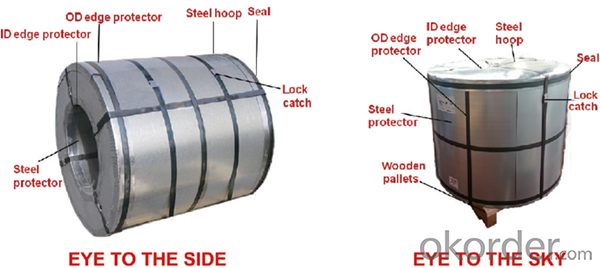

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Services:

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. Can you offer OEM to me? What about MOQ?

Of course, we are a professional with OEM manufacturer for 9 years. the MOQ can be 50 ton/ order.

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we

have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will

provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing

as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

4.How Can I Get Some Sample?

We are honored to offer you free sample, but courier charges will be on your side.

- Q: What is the (balanced) chemical equation for steel?

- Steel is about 5% carbon and about 89 % iron, the rest is impurities of all sorts That is considered low carbon steel There are precise formulas for other steels like High Speed Steel, High Tensile low carbon, and thousands of other steels. Specialty steels are a big business item with thousand of tons sold each year for specialty applications.

- Q: Can steel coils be welded together?

- Yes, steel coils can be welded together. Welding is a common technique used to join metals, including steel coils. It involves melting the edges of the coils and fusing them together using a filler material. This process creates a strong and durable bond between the coils, allowing them to be joined and used as a single unit. Welding steel coils together is commonly done in various industries, such as manufacturing, construction, and automotive, to create larger structures or components. However, it is important to ensure proper welding techniques and quality control measures are followed to ensure the integrity and strength of the weld joint.

- Q: i found a similar question asking what metals were in stainless steel but i don't know if they are the same.... they probably aren't.

- steel is iron with a little bit of carbon mixed in. how much carbon determines the hardness of the steel. stainless steel is the same mostly, it has nickle and chromium added in to make it corrosion resistant.

- Q: Where can you buy a steel polearm in a shop or if someone has a file in Scania than can you sell me one ill buy it for 150k my account is tonypark500

- Steel polearm was from the Aran Welcome Event, which ended a few weeks ago. Now is the worst time to buy one, since the craze just ended and steel polearms are now heavily in demand (sadly). Your best bet is the free market, but they will cost you a few mil.

- Q: Are steel buildings or homes better then wooden buildings? Why?

- Arch steel buildings are extremely easy to put up as compared to other conventional structures you don't need any type of heavy equipment to erect your steel arch buildings. Most of the people put their steel buildings up with the help of family or friends in just a couple of days.

- Q: What are the environmental impacts of producing steel coils?

- The production of steel coils has several environmental impacts. Firstly, it involves the extraction of iron ore, which requires mining activities. These mining operations can lead to deforestation, habitat destruction, and soil erosion. Additionally, the extraction and processing of iron ore require large amounts of energy, contributing to greenhouse gas emissions and air pollution. Furthermore, the production of steel coils involves several stages, such as smelting and refining, which are energy-intensive and emit significant amounts of carbon dioxide, sulfur dioxide, and nitrogen oxides. These emissions contribute to air pollution, acid rain, and climate change. Water consumption is another notable environmental impact. Steel production requires large volumes of water for cooling and processing purposes. This high water demand can strain local water resources and potentially lead to water scarcity or pollution if not managed properly. Moreover, the steel industry generates substantial amounts of waste and by-products, such as slag, dust, and sludge. Proper disposal and treatment of these waste materials are crucial to prevent soil and water contamination. Lastly, transportation plays a role in the environmental impact of steel coil production. The transportation of raw materials and finished products can contribute to carbon emissions and air pollution, especially if long distances are involved. To mitigate these environmental impacts, various measures can be taken. Implementing more efficient production processes, such as recycling and using renewable energy sources, can reduce energy consumption and emissions. Additionally, improving waste management practices, investing in water conservation technologies, and optimizing transportation logistics can help minimize the environmental footprint of steel coil production.

- Q: How are defects in steel coils repaired?

- Defects in steel coils are repaired through various methods depending on the type and severity of the defect. Common repair techniques include grinding, welding, soldering, or using heat treatment processes to correct the defects. The specific approach is determined by professionals after assessing the nature of the defect and considering the desired quality and performance standards of the steel coils.

- Q: Can we construct a barn using steel and will it be a durable one?

- Barns can be constructed out of a number of materials be it steel, block or wood. Among all the available materials, steel offers the best in terms of strength, durability and pricing. Constructing a barn using wood can be a costly task because of the high price of wood. On the other hand, constructing a barn using block consumes more time and involves a much more professional approach thereby increasing the labor costs. Considering all these factors, it is always recommended to go for steel barns due to their durability, robustness and longer life span.

- Q: Can steel coils be used in outdoor applications?

- Yes, steel coils can be used in outdoor applications. Steel is known for its durability and strength, making it suitable for a wide range of outdoor uses. Steel coils are often used in applications such as construction, automotive manufacturing, and transportation industries. They are resistant to harsh weather conditions, including rain, snow, and UV exposure. Additionally, steel coils are often coated with protective finishes, such as galvanized or painted coatings, to further enhance their resistance to corrosion and extend their lifespan. Overall, steel coils are a reliable and versatile option for outdoor applications due to their strength, durability, and resistance to environmental factors.

- Q: What are the different types of steel coil handling devices?

- There are several types of steel coil handling devices, including coil lifters, coil grabs, coil tongs, coil hooks, and coil transfer cars.

Send your message to us

Steel prices cold rolled china express Alibaba

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 58357 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords