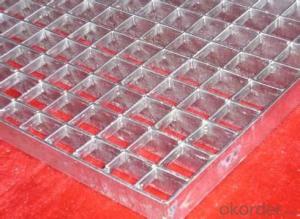

Steel Lattice Panel Grating

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Superiority and application area

1. Material saving: It is the most material saving way under the same loading condition,can saving more backstand materials.

2. Investment reduction: Material saving, manual work saving, erection time saving, no need to clean and maintenance.

3. Easy erection working: Fix with bolt, on pre-set structure, one worker can finish.

4. Working time saving: No need rework on site, fast installation.

5. Durable in use: Hot zip galvanized and anti-rust treated before sell, durable in impact and pressure, have modern and fashion feeling.

6. Light structured: Less material, lighter structure, easier installation.

7. Dust and rubbish avoidable: Avoid cumulating of rain, snow, ice and dust.

8. Wind resistance reducing: Better in airiness, less wind resistance, reducing wind destroy.

9. Design simplified: No small support required, simple structure and design, no detailed grating design drawing required, only need to inform the ref number, the factory can design typeset for the customer.

10. Good at airiness, lighting, heat elimination, anti-riot, and anti-slip.

Usage/Applications of Steel Flat Bar

Widely used for construction, Machinery manufacturing, Iron tower steel structure, Shipbuilding; Steel grating, Staircase, Bridge, Viaduct, Railway spare parts, Boilers making etc.

Production Flow of Steel Flat Bar

The steel flat bar is made through three processes:

1.Feeding the material: Feeding the row material (the steel plate) to Slitting Line.

2.Slitting:The steel plate would be slitted into expected width by lengthways cutter.

3. Leveled and cutting: The plat bar would be ground into level by the grinder and then cut into required length.

Packaging & Delivery of Steel Flat Bar

Packaging Details: The Steel Flat Bars are packed in bundles and loaded in 20 feet/40 feet container, or shipped by bulk cargo ,also we can do as customer's requirements.

Delivery Details:30~45 days upon the receipt of buyer payment by T.T. or L/C.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: What makes stainless steel stainless?

A2: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q3: Can stainless steel rust?

A3: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

- Q: How strong are steel flat bars?

- Steel flat bars are known for their strength and durability. The specific strength of steel flat bars can vary depending on the grade of steel used and the dimensions of the bar. However, in general, steel flat bars are considered to be quite strong due to the inherent properties of steel, making them suitable for a wide range of structural and industrial applications.

- Q: Can steel flat bars be used in the construction of industrial structures?

- Yes, steel flat bars can be used in the construction of industrial structures. Steel flat bars are versatile and strong, making them suitable for a wide range of applications in industrial construction. They are commonly used in the construction of beams, columns, frames, and supports. Steel flat bars offer excellent structural integrity and are able to withstand heavy loads and high-stress conditions. Additionally, they are durable, corrosion-resistant, and require minimal maintenance. The versatility and strength of steel flat bars make them an ideal choice for the construction of industrial structures.

- Q: Can steel flat bars be used for structural applications?

- Yes, steel flat bars can be used for structural applications. They are commonly used in the construction industry for various structural purposes such as building frames, supports, and bracing. The high strength and durability of steel make flat bars suitable for carrying heavy loads and providing structural stability.

- Q: What is the difference between hot-rolled and cold-rolled steel flat bars?

- The production process and resulting characteristics distinguish hot-rolled steel flat bars from cold-rolled steel flat bars. Hot-rolled bars are created by heating a steel billet or slab to a high temperature and then rolling it through a series of rollers to achieve the desired shape and size. This results in a relatively rough surface and rounded edges. In contrast, cold-rolled bars are produced by cooling down the hot-rolled steel to room temperature and passing it through a series of rollers at room temperature. This process yields a smoother surface finish and sharper edges compared to hot-rolled bars. Regarding physical properties, hot-rolled bars generally have a larger size tolerance due to possible dimensional variations caused by the high-temperature rolling process. On the other hand, cold-rolled bars have a tighter size tolerance as a result of the controlled cold-rolling process. Furthermore, hot-rolled bars often have a scaled surface due to the heating and cooling process involved in their production. This scaled surface consists of a thin layer of iron oxide. In contrast, cold-rolled bars have a clean and smooth surface. Moreover, the mechanical properties of hot-rolled and cold-rolled bars differ. Hot-rolled bars tend to have lower yield strength and higher ductility, making them suitable for applications requiring shaping or bending. Conversely, cold-rolled bars have higher yield strength and lower ductility, making them more suitable for applications necessitating strength and durability. In summary, the primary differences between hot-rolled and cold-rolled steel flat bars lie in their production process, surface finish, dimensional tolerance, and mechanical properties. The choice between the two depends on the specific requirements of the application and the desired characteristics of the steel flat bars.

- Q: Can steel flat bars be used for making blades or cutting edges?

- Steel flat bars are suitable for creating blades or cutting edges. Steel, a robust and long-lasting material, finds wide usage in the fabrication of different tools and equipment. Once properly shaped and sharpened, steel flat bars can be converted into highly efficient blades or cutting edges.

- Q: What is the difference between steel band and steel ring? The steel strip is flat steel and the steel ring is made of steel. Am I right?

- A steel strip is a steel strip of relative range, and can be called a steel strip when the width is less than 1000.

- Q: How do steel flat bars perform in high-pressure environments?

- Steel flat bars are known for their excellent strength and durability, making them suitable for high-pressure environments. The flat shape of these bars allows them to distribute pressure evenly, minimizing the risk of deformation or failure under extreme conditions. In high-pressure environments, steel flat bars exhibit remarkable resistance to bending and breaking, ensuring the structural integrity of various applications. Their high tensile strength enables them to withstand significant pressure without compromising their performance. Additionally, the hardness of steel bars helps them resist wear and abrasion, making them ideal for environments where high pressures are coupled with harsh conditions. Steel flat bars also possess good corrosion resistance, which is crucial in high-pressure environments where exposure to moisture or corrosive substances is common. They can be further enhanced through protective coatings or treatments to provide even greater resistance against corrosion. Moreover, steel flat bars have excellent weldability, allowing for easy fabrication and customization to suit specific high-pressure applications. This flexibility enables engineers and designers to utilize steel flat bars in various industries, such as construction, manufacturing, and oil and gas. However, it is important to consider the specific requirements and properties of the steel flat bars used in high-pressure environments. Factors such as the grade of steel, dimensions, and manufacturing process can influence their performance. Consulting with a materials expert or referring to industry standards and guidelines can help ensure the appropriate selection and utilization of steel flat bars in high-pressure applications.

- Q: What does QB stand for in Q235B flat steel? What's the difference between Q235B and Q235A?

- There are also some subtle differences between Q235A and Q235B:1, chemical composition: Q235A:C:0.14~0.22:Mn:0.30~0.65; S:0.050;2, mechanical properties: tensile test without distinction, impact test A do not do, Q235B I-beam, Q235B angle steel, Q235B channel steel, Q235BH steel, Q235B flat steel B do 20 degree impact test, V type impact power (longitudinal) J no less than 27.

- Q: Can steel flat bars be used for making tools or machinery?

- Yes, steel flat bars can be used for making tools or machinery. Steel is a widely used material in tool and machinery manufacturing due to its high strength, durability, and versatility. Steel flat bars can be easily shaped, cut, or welded to create various tools and machine parts, making them a suitable choice for such applications.

- Q: Can steel flat bars be used in the automotive industry?

- Yes, steel flat bars can be used in the automotive industry. Steel is a widely used material in the automotive industry due to its strength, durability, and versatility. Steel flat bars can be used for various applications in the automotive industry, including structural components, chassis, body panels, suspension systems, and engine components. The flat shape of the bars allows for easy fabrication, cutting, and welding, making them suitable for different automotive manufacturing processes. Additionally, steel flat bars are available in different grades and thicknesses, allowing manufacturers to choose the appropriate type of steel for their specific automotive applications. Overall, steel flat bars are a reliable and cost-effective option for the automotive industry, providing the necessary strength and performance required for vehicles.

Send your message to us

Steel Lattice Panel Grating

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords