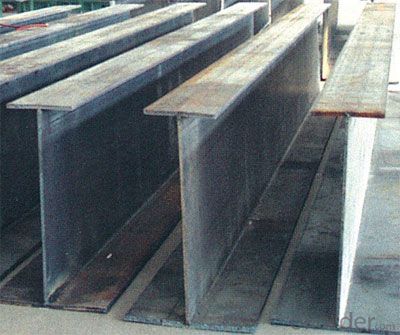

Steel H Beam Stock Quantity 2000 Tons All Size JIS Building Structual Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of Steel H Beam Stock Quantity 2000 Tons All Size JIS Building Structual Material:

OKorder is offering Steel H Beam Stock Quantity 2000 Tons All Size JIS Building Structual Material at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications of Steel H Beam Stock Quantity 2000 Tons All Size JIS Building Structual Material:

Steel H Beam Stock Quantity 2000 Tons All Size JIS Building Structual Material are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

H beam is widely used in various building structure and engineering structure:

a).used for the plant, high-rise building construction

b).used for the bridge, shipment building

c).used for lifting and transportation machinery, equipment manufacturing base building

d).used for the support, foundation pile manufacturing

Main Product Features of Steel H Beam Stock Quantity 2000 Tons All Size JIS Building Structual Material:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications of Steel H Beam Stock Quantity 2000 Tons All Size JIS Building Structual Material:

1. Standard: JIS G3192 OR GB/T11263-2005

2. Grade: Q235/SS400/S235JR

3. Length: 6m-12m

4. Packing:standard export packagin

| STANDARD: JIS G3192 OR GB/T11263-2005 | |||

| H beam Section sizenma(mm) | Weight (kg/m) | ||

| Height×Breadth | Web thichness | Flange thichness | |

| 100×100 | 6 | 8 | 16.9 |

| 125×125 | 6.5 | 9 | 23.6 |

| 150×150 | 7 | 10 | 31.1 |

| 175×175 | 7.5 | 11 | 40.4 |

| 200×200 | 8 | 12 | 49.9 |

| 250×250 | 9 | 14 | 71.8 |

| 300×300 | 10 | 15 | 93.0 |

| 300×300 | 15 | 15 | 105.0 |

| 350×350 | 12 | 19 | 134.9 |

| 400×400 | 13 | 21 | 171.7 |

| 148×100 | 6 | 9 | 20.7 |

| 194×150 | 6 | 9 | 29.9 |

| 244×175 | 7 | 11 | 43.6 |

| 294×200 | 8 | 12 | 55.8 |

| 340×250 | 9 | 14 | 78.1 |

| 390×300 | 10 | 16 | 104.6 |

| 440×300 | 11 | 18 | 120.8 |

| 482×300 | 11 | 15 | 110.8 |

| 488×300 | 11 | 18 | 124.9 |

| 582×300 | 12 | 17 | 132.8 |

| 588×300 | 12 | 20 | 147.0 |

| 100×50 | 5 | 7 | 9.3 |

| 125×60 | 6 | 8 | 13.1 |

| 150×75 | 5 | 7 | 14.0 |

| 175×90 | 5 | 8 | 18.0 |

| 198×99 | 4.5 | 7 | 17.8 |

| 200×100 | 5.5 | 8 | 20.9 |

| 248×124 | 5 | 8 | 25.1 |

| 250×125 | 6 | 9 | 29.0 |

| 298×149 | 5.5 | 8 | 32.0 |

| 300×150 | 6.5 | 9 | 36.7 |

| 346×174 | 6 | 9 | 41.2 |

| 350×175 | 7 | 11 | 49.4 |

| 396×199 | 7 | 11 | 56.1 |

| 400×200 | 8 | 13 | 65.4 |

| 446×199 | 8 | 12 | 65.1 |

| 450×200 | 9 | 14 | 74.9 |

| 496×199 | 9 | 14 | 77.9 |

| 500×200 | 10 | 16 | 88.1 |

| 596×199 | 10 | 15 | 92.4 |

| 600×200 | 11 | 17 | 103.4 |

| 700×300 | 13 | 24 | 181.8 |

| 800×300 | 14 | 26 | 206.8 |

| 900×300 | 16 | 28 | 240.1 |

- Q: How do Steel H-Beams contribute to the overall architectural design of a structure?

- Steel H-beams are vital to the architectural design of structures as they offer essential support and stability. These beams are designed specifically to handle heavy loads and distribute weight efficiently, making them perfect for constructing large-scale buildings, bridges, and industrial facilities. One of the key advantages of steel H-beams is their ability to span long distances without the need for additional support columns or walls. This allows architects to create open and flexible floor plans, maximizing usable space. The absence of intermediate columns not only enhances aesthetics but also allows for the creation of large, uninterrupted areas. In addition to their functional benefits, steel H-beams also provide aesthetic advantages to architectural design. Their sleek and modern appearance, characterized by clean lines and a minimalist design, adds sophistication and elegance to contemporary and industrial-style structures. Furthermore, steel H-beams are highly versatile and can be easily integrated into various architectural styles. Whether it's a traditional or modern structure, these beams offer flexibility for architects to create unique and innovative designs that meet both functional and aesthetic requirements. Moreover, steel H-beams contribute to the overall architectural design by ensuring structural integrity and durability. The use of high-strength steel guarantees the ability to withstand heavy loads, environmental forces, and natural disasters. This durability not only ensures the safety of occupants but also reduces maintenance and repair costs over time. In conclusion, steel H-beams are essential elements in the architectural design of structures, providing support, stability, flexibility, and durability. Whether it's a commercial building, a residential project, or an industrial facility, these beams play a crucial role in the success and functionality of the overall design.

- Q: What are the common design considerations for steel H-beams in roofing applications?

- To ensure the structural integrity and safety of a roof, it is important to consider various design factors when using steel H-beams in roofing applications. 1. Load-bearing capacity: The steel H-beams must be designed to withstand the weight of the roof and any additional loads, such as snow, wind, or equipment. It is essential to properly size and space the beams to evenly distribute the loads and prevent any potential failure or collapse. 2. Span and support spacing: Careful consideration should be given to determining the span and support spacing of the steel H-beams based on the specific roof design and anticipated loads. Adequate support is necessary to prevent excessive deflection, sagging, or bending. The spacing between the beams should adhere to engineering standards and codes. 3. Connection details: The connections between the steel H-beams and other structural elements, such as columns or purlins, should be meticulously designed and executed. Strong and secure connections are crucial for proper load transfer and to avoid any disconnection or failure. 4. Fire resistance: Steel H-beams used in roofing applications should be designed to provide sufficient fire resistance. This can be achieved through the use of fire-resistant coatings, insulation materials, or the incorporation of fire-rated materials into the design. 5. Corrosion protection: Steel H-beams are susceptible to corrosion, particularly in outdoor roofing applications where they are exposed to the elements. It is necessary to implement appropriate corrosion protection measures, such as galvanizing or using corrosion-resistant coatings, to prolong the lifespan of the beams and maintain their structural integrity. 6. Thermal expansion and contraction: The design of steel H-beams should account for thermal expansion and contraction caused by temperature variations. This can be achieved by incorporating expansion joints or allowing for appropriate clearance and movement in the design. 7. Sustainability considerations: In modern design, sustainability plays a crucial role. Utilizing recycled steel or incorporating energy-efficient design elements can contribute to the overall sustainability of the roofing system. In conclusion, when designing steel H-beams for roofing applications, it is important to consider load-bearing capacity, span and support spacing, connection details, fire resistance, corrosion protection, thermal expansion and contraction, and sustainability. Addressing these design considerations will ensure that the steel H-beams provide a safe and durable roofing solution.

- Q: What are the considerations when designing connections for Steel H-Beams?

- When it comes to designing connections for Steel H-Beams, there are several crucial factors to bear in mind. The primary concern is to guarantee the structural integrity and safety of the connection. This entails conducting calculations to determine the loads and forces that the connection will endure, such as gravity loads, lateral loads, and wind loads. These calculations will help ascertain the appropriate size and type of connection needed to withstand these forces. Another factor to consider is the specific H-beam being utilized and its unique properties. Different H-beams will have varying dimensions, strengths, and load capacities, so it is essential to select a connection that is compatible with the particular H-beam being used. Additionally, the connection must be designed to accommodate any potential movement or deflection of the H-beam, such as thermal expansion or contraction. The choice of connection method is also a significant consideration. There are various options available, including welding, bolting, or a combination of both. Each method has its own advantages and limitations, such as cost, ease of installation, and the ability to withstand different types of loads. The selection of the connection method will depend on factors such as the project requirements, available resources, and specific design considerations. Furthermore, the location and environment in which the connection will be installed should be taken into account. Factors such as exposure to corrosive substances, extreme temperatures, or high humidity can impact the durability and longevity of the connection. In such cases, appropriate protective measures, such as coatings or galvanization, may be necessary to prevent corrosion and ensure the connection's longevity. Lastly, it is crucial to consider any applicable codes, standards, and regulations when designing connections for Steel H-Beams. These codes and standards provide guidelines and requirements for the design, fabrication, and installation of structural connections, ensuring they meet safety and performance criteria. Compliance with these codes and standards is vital to ensure the connection functions as intended and meets the necessary safety standards. In conclusion, the design of connections for Steel H-Beams necessitates careful consideration of the loads and forces involved, the properties of the H-beam, the method of connection, the installation environment, and compliance with applicable codes and standards. By taking these considerations into account, a safe, efficient, and durable connection can be designed for Steel H-Beams.

- Q: How do you calculate the shear stress in steel H-beams?

- To calculate the shear stress in steel H-beams, you need to determine the applied shear force and divide it by the cross-sectional area of the beam's web. This will give you the shear stress acting on the beam.

- Q: How to distinguish between narrow flange and wide flange H section steel

- I as the name suggests, is a kind of I-shaped section steel flange on the inner surface of slope is generally 1:6, the flange and the thickness of thin, resulting in two main characteristics of I-beam section plane is huge, it is difficult to play the strength of steel in the application, as the first picture shows. Although there has been a thicker I-beam in the I-beam market, the structure of the I-beam has determined its torsional properties.

- Q: How do steel H-beams compare to I-beams in terms of strength?

- Steel H-beams are generally stronger than I-beams due to their wider flange and greater cross-sectional area, which allows them to withstand higher loads and provide better structural support.

- Q: Can steel H-beams be used for architectural purposes?

- Yes, steel H-beams can be used for architectural purposes. H-beams, also known as I-beams or W-beams, are widely used in the construction industry due to their strength, durability, and versatility. They have a distinct H-shape, with two flanges on either side connected by a web in the center, which provides excellent load-bearing capabilities. Architects often utilize steel H-beams in various architectural applications. They are commonly used in the construction of large buildings, bridges, and other structures where strength and stability are essential. H-beams provide structural support, allowing architects to design open and spacious interiors without the need for excessive columns or walls. Steel H-beams are also used in the creation of architectural features and elements. They can be used to create large windows, curtain walls, canopies, and other aesthetic elements. H-beams can be easily connected and welded, allowing for the creation of intricate and unique designs. Furthermore, steel H-beams are often used in the construction of sustainable buildings. They are frequently used in green building projects due to their recyclability and low environmental impact. Using steel H-beams in architectural designs allows for efficient use of materials and reduces waste. In conclusion, steel H-beams are a popular choice for architectural purposes. Their strength, durability, and versatility make them suitable for a wide range of construction applications. Architects can rely on H-beams to provide structural support, create unique designs, and contribute to sustainable building practices.

- Q: How is the weight of H steel calculated?

- RA=RB=P/2 Mc=Mmax=Pl/4 fc=fmax=Pl^3/48EI A= B=Pl^2/16EI symbol and theta theta P - Q - N; concentrated load, uniform load, N; R - bearing force, the direction of the action is positive, N; M - bending moment, the compression of the upper section, lower tension is positive, Nm; Q, the shear. The adjacent section of the torque in a clockwise direction is positive, N; F, deflection, downward displacement is positive, mm; angle theta, clockwise rotation as positive degrees; E - Gpa; I - elastic modulus, cross-sectional moment of inertia, m^4; L = x/. =x'/l, zeta, alpha beta gamma = a/l, =b/l, =c/l from two aspects: first, from the beam considering shear stress second, the bending stress is considered. The maximum available shear strength of steel can be found from the steel sheet, T, Tmax=Q/Ib[BH^2/8-< (B-b), h^2>/8]: Tmax is the maximum shear strength. The maximum shear load of the beam can be calculated by replacing the available shear strength T. Q is the uniformly distributed load, and the section moment of inertia of I is B, which can be found in the steel table. (cm^4) the maximum width of the section of i-beam. B is the minimum width of I-beam section, h is the height of minimum width section of i-beam. H is the calculation of the height normal stress of the maximum width section of I-beam: Ysigma=M/W, M=, maximum bending moment = load, travel distance, W= flexural modulus. With the maximum allowable stress of Ysigma=, the maximum value of the load can be obtained.

- Q: What are the different fabrication methods for steel H-beams?

- Steel H-beams can be manufactured using several fabrication methods, such as hot rolling, cold rolling, and welding. The most commonly used method for fabricating steel H-beams is hot rolling. This involves heating a steel billet to a high temperature and then passing it through rolling stands to shape it into the desired H-beam profile. The elevated temperature makes the steel more malleable, allowing for easy formation into the H-shape. This technique produces high-quality H-beams with exceptional structural integrity. Another fabrication method is cold rolling, where the steel is passed through rolling stands at room temperature. This process enhances the surface finish and dimensional accuracy of the H-beams. Cold rolling is typically employed for producing smaller and lighter H-beams, which are often used in applications where weight and size are crucial factors. Welding is also utilized in the fabrication of steel H-beams. This method involves joining individual steel plates or sections together to create the H-beam shape. Welding offers greater flexibility in terms of size and shape, making it suitable for custom or non-standard applications. However, it should be noted that welded H-beams may have slightly lower structural integrity compared to those produced through hot or cold rolling. The choice of fabrication method for steel H-beams depends on various factors, including size, shape, and application requirements. Each method has its own advantages and limitations, and manufacturers carefully select the most suitable approach based on the specific project needs.

- Q: Can steel H-beams be used for gymnasiums?

- Gymnasiums can indeed utilize steel H-beams. Due to their robustness and structural soundness, steel H-beams are widely employed in construction. They provide exceptional support for substantial spans and heavy loads, making them ideal for gymnasiums, which often necessitate expansive areas and lofty ceilings. Moreover, steel H-beams can be effortlessly tailored and manufactured to meet specific design prerequisites, granting flexibility in gymnasium design. Their resilience and ability to withstand fire, pests, and structural deterioration also establish them as a dependable choice for gymnasium construction. All in all, steel H-beams represent a favored and efficient alternative for constructing gymnasiums.

Send your message to us

Steel H Beam Stock Quantity 2000 Tons All Size JIS Building Structual Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords