Steel Flat Bar Hot Rolled Retangular Section with Light Weight

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Steel Flat Bar Hot Rolled Retangular Section Description:

Steel flat bar hot rolled retangular section is a beam with an I-shaped cross-section. The horizontal elements of the "I" are known as flanges, while the vertical element is termed the "web". Steel flat bar hot rolled retangular section is usually made of structural steel and is used in construction and civil engineering. The steel flat bar hot rolled retangular section resists shear forces, while the flanges resist most of the bending moment experienced by the beam. Steel flat bar hot rolled retangular section theory shows that the I-shaped section is a very efficient form for carrying both bending and shears loads in the plane of the web.

2. Main Features of Steel Flat Bar Hot Rolled Retangular Section:

• Grade: Q235

• Type: Mild carbon steel

• Deflection: The stiffness of the I-beam will be chosen to minimize deformation

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

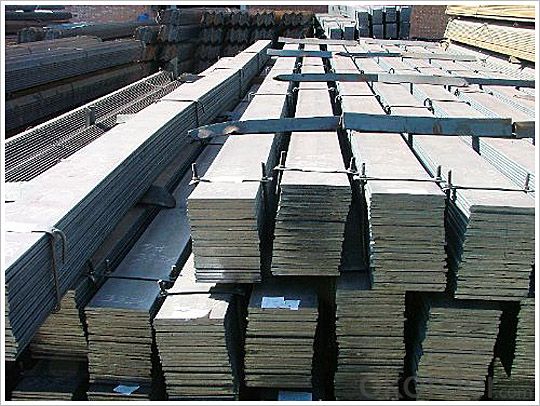

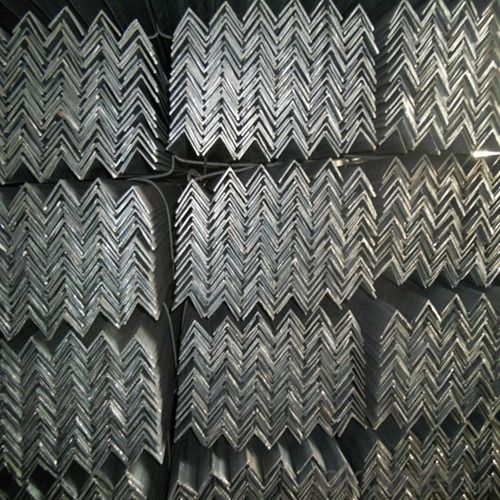

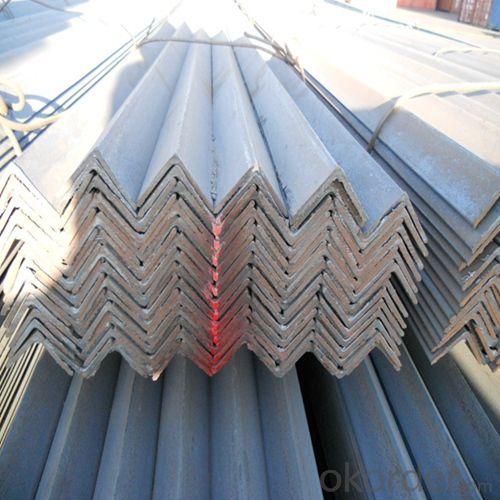

3. Steel Flat Bar Hot Rolled Retangular Section Images:

4. Steel Flat Bar Hot Rolled Retangular Section Specification:

Mechanical Properties | Grade | Steel diameter(mm) | |||

≤16 | 16~40 | 40~60 | 60~100 | ||

Yield Point Δs/MPa | Q195 | ≥195 | ≥185 | - | - |

Q235 | 235 | 225 | 215 | 205 | |

Tensile Strength | Q195 | 315~390 | |||

Q235 | 375~500 | ||||

Elongation δ5% | Q195 | ≥33 | ≥32 | - | - |

Q235 | 26 | 25 | 24 | 23 | |

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①Is this product same as W beam?

In the United States, the most commonly mentioned I-beam is the wide-flange (W) shape. These beams have flanges in which the planes are nearly parallel. Other I-beams include American Standard (designated S) shapes, in which flange surfaces are not parallel, and H-piles (designated HP), which are typically used as pile foundations. Wide-flange shapes are available in grade ASTM A992,[4] which has generally replaced the older ASTM grades A572 and A36.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q: What is the negative deviation allowed by the national standard for galvanized flat steel of 40*4?

- 40*4 galvanized flat steel GB permitted negative deviation value is the thickness deviation value is 0.2mm, the deviation 0.4mm, the width deviation value is the upper deviation 0.5mm, lower deviation 1.0mm

- Q: What are the different types of surface coatings available for steel flat bars?

- Some of the different types of surface coatings available for steel flat bars include galvanized coatings, paint coatings, powder coatings, and epoxy coatings. These coatings provide protection against corrosion, enhance the appearance of the steel, and can also provide additional functional properties such as improved resistance to chemicals or abrasion.

- Q: How are steel flat bars manufactured?

- Steel flat bars undergo a process called hot rolling to be manufactured. This process entails heating a steel billet or ingot above its recrystallization temperature, usually around 1,000 to 1,300 degrees Celsius. The heated steel is then passed through a series of rollers to gradually decrease its thickness and shape it into a flat bar. In the hot rolling process, the steel is initially descaled to eliminate any surface impurities and oxides. It then goes through a roughing mill, which consists of multiple sets of large rollers that progressively reduce the steel's thickness. The steel is continuously reheated and passed through the rollers until it reaches the desired thickness. Once the steel has reached the desired thickness through roughing, it moves on to a finishing mill. This mill features smaller rollers that further decrease the thickness of the steel and enhance its surface finish. The steel is rolled back and forth between these rollers until it reaches its final thickness, typically ranging from 3 to 25 millimeters. After the final rolling, the steel flat bar is cooled using water or air to temper it and improve its mechanical properties. It is then cut to the desired length and may undergo additional processes like straightening or surface treatments, depending on its intended use. In summary, the manufacturing process of steel flat bars involves hot rolling, which encompasses descaling, roughing, finishing, cooling, and final processing stages to produce flat bars with various thicknesses and lengths.

- Q: Can steel flat bars be used for manufacturing storage racks?

- Yes, steel flat bars can be used for manufacturing storage racks. Steel flat bars are known for their strength and durability, making them an excellent choice for constructing storage racks that need to support heavy loads. The flat shape of the bars also provides a stable surface for storing various items. Additionally, steel flat bars can be easily welded or bolted together to create the desired rack configuration, making them versatile and customizable for different storage needs.

- Q: Can steel flat bars be heat treated for increased strength?

- Steel flat bars have the ability to undergo heat treatment for the purpose of enhancing their strength. Heat treatment involves subjecting the steel to a specific temperature, maintaining it at that temperature for a specific duration, and then carefully cooling it. This process results in changes to the steel's microstructure, leading to improved mechanical properties, such as increased strength. The choice of heat treatment method depends on the desired strength and other required properties for the specific application of the steel flat bars. Common heat treatment techniques for steel encompass annealing, quenching, tempering, and normalizing. It is crucial to seek guidance from a metallurgical engineer or expert to determine the most suitable heat treatment approach for achieving the desired strength enhancement in steel flat bars.

- Q: Can steel flat bars be threaded?

- No, steel flat bars cannot be threaded. Threading is a process of creating helical grooves on the surface of a material to allow for the attachment of fasteners or other components. Steel flat bars, as the name suggests, have a flat surface and lack the necessary features to accommodate threading. However, if there is a need for threaded connections, alternative steel products such as threaded rods or pipes can be used.

- Q: What are the common safety precautions when working with steel flat bars?

- When working with steel flat bars, there are several common safety precautions that should be followed to ensure the safety of the workers. 1. Personal Protective Equipment (PPE): The first and foremost precaution is to wear appropriate PPE. This includes safety glasses or goggles to protect the eyes from any flying debris or sparks, gloves to protect hands from sharp edges, and steel-toe boots to protect feet from heavy objects or falling materials. 2. Proper Lifting Techniques: Steel flat bars can be heavy, so it is important to use proper lifting techniques to prevent back or muscle injuries. Lift with your legs, not your back, and avoid twisting or jerking movements while lifting. 3. Secure Storage: When not in use, steel flat bars should be stored in a secure and organized manner. This prevents any accidental tripping or falling hazards. Additionally, heavy steel flat bars should be stored at a lower height to avoid any potential injuries caused by falling objects. 4. Safe Handling: When handling steel flat bars, it is important to be cautious of sharp edges and corners. Workers should always be mindful of their surroundings and avoid any sudden movements that could cause injury. Proper lifting equipment, such as lifting clamps or tongs, should be used when necessary to ensure a secure grip on the bars. 5. Fire Safety: Steel flat bars can produce sparks when being cut or welded. Therefore, it is essential to have a fire extinguisher nearby and ensure proper ventilation in the workspace to prevent the buildup of flammable gases or fumes. 6. Training and Education: All workers should receive proper training and education on the safe handling and use of steel flat bars. This includes understanding the correct tools and equipment to use, as well as the potential hazards associated with working with steel flat bars. By following these common safety precautions, workers can minimize the risk of accidents, injuries, and ensure a safe working environment when working with steel flat bars.

- Q: What are the different methods of joining steel flat bars together?

- There are several methods of joining steel flat bars together, each with its own advantages and disadvantages. Here are some of the most common methods: 1. Welding: Welding is the most common method of joining steel flat bars together. It involves melting the edges of the bars and fusing them together using heat. This creates a strong and permanent bond. There are different types of welding techniques, such as arc welding, MIG welding, and TIG welding, which can be used depending on the specific requirements of the project. 2. Bolting: Bolting is another method used to join steel flat bars together. It involves drilling holes in the bars and then using bolts, nuts, and washers to secure them. This method allows for easy disassembly and reassembly, making it suitable for applications that require frequent maintenance or adjustments. 3. Riveting: Riveting involves inserting a rivet, a metal pin or bolt, through holes drilled in the bars and then deforming the end to create a head, securing the bars together. This method provides a strong and durable connection and is commonly used in structural applications. 4. Adhesive bonding: Adhesive bonding involves using a suitable adhesive or epoxy to bond the steel flat bars together. This method is commonly used when welding or bolting is not feasible or desired. Adhesive bonding can provide a strong and corrosion-resistant joint, but it may not be as structurally strong as other methods. 5. Clamping: Clamping is a temporary method used to hold steel flat bars together. It involves using clamps or vices to apply pressure and hold the bars in place. This method is often used during the welding or adhesive bonding process to ensure a tight fit and prevent movement. It is important to consider the specific requirements of the project, such as strength, durability, disassembly needs, and aesthetic appearance, when choosing the appropriate method to join steel flat bars together.

- Q: What are the different types of tests performed on steel flat bars?

- There are several types of tests that are commonly performed on steel flat bars to ensure their quality and suitability for various applications. These tests aim to assess the strength, durability, and other mechanical properties of the steel. Some of the different types of tests performed on steel flat bars include: 1. Tensile Test: This test measures the maximum amount of tensile stress that a steel flat bar can withstand before it fractures. It helps determine the yield strength, ultimate tensile strength, and elongation of the material. 2. Hardness Test: The hardness of a steel flat bar is an important characteristic to determine its resistance to deformation, wear, and abrasion. Various methods such as Rockwell, Brinell, and Vickers hardness tests are used to measure the hardness of the steel. 3. Impact Test: This test helps evaluate the ability of the steel flat bar to absorb energy under high-stress conditions. It involves striking the material with a pendulum to measure the amount of energy absorbed and its ability to resist cracking or breaking. 4. Bend Test: The bend test assesses the ductility and flexibility of the steel flat bar by bending it to a specified angle without fracture. It helps determine if the material is suitable for applications that involve bending or forming processes. 5. Chemical Analysis: Chemical analysis is performed to determine the composition of the steel flat bar, including the percentage of various elements such as carbon, manganese, silicon, and others. This analysis ensures that the steel meets the required specifications and standards. 6. Ultrasonic Testing: Ultrasonic testing uses high-frequency sound waves to detect internal flaws or defects in the steel flat bar. It helps identify cracks, voids, or inclusions that may affect the overall integrity and strength of the material. 7. Dimensional Inspection: This test ensures that the steel flat bar meets the required dimensional tolerances and specifications. It involves measuring the length, width, thickness, and other dimensions of the bar to ensure it meets the desired standards. 8. Microstructure Analysis: Microstructure analysis involves examining the metallurgical structure of the steel flat bar under a microscope. It helps identify the grain size, phase distribution, and any abnormalities that may affect the material's mechanical properties. By performing these various tests, manufacturers, suppliers, and end-users can ensure that steel flat bars meet the necessary quality standards and are suitable for their intended applications.

- Q: Can steel flat bars be used for fencing or railing?

- Indeed, fencing or railing can benefit from the utilization of steel flat bars. These bars, renowned for their robustness and longevity, are frequently employed in construction endeavors. As pickets for fences or balusters for railings, they fulfill their purpose admirably. The bars' flat configuration facilitates effortless installation while exuding a contemporary and sophisticated aesthetic. Moreover, personalizing steel flat bars to harmonize with specific designs is a breeze, and safeguarding against rust and corrosion can be achieved through painting or coating. In summary, the durability and adaptability of steel flat bars render them an optimal choice for fencing or railing undertakings.

Send your message to us

Steel Flat Bar Hot Rolled Retangular Section with Light Weight

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords