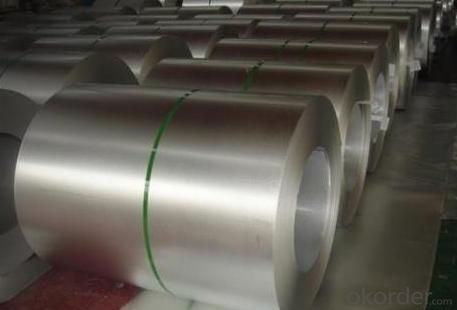

Steel Coil or Sheet Cold Rolled of JIS G3141-1996, EN 10131-2006, DIN EN 1002

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Refrigerators, cabinets, power distribution baords and drums.

Automobile floor and roof panels.

Description

1) Product Name: Cold rolled Steel Coil/sheet/strip

2) Thickness: 0.16mm-1.0mm

3) Width:30mm-1250mm

4) Length: As requested

5) Width tolerance: different as per different width

6) Thickness tolerance: different as per different thickness

7) Weight: According to the different requirement

8) Packing: Mill standard export packing in bundles

9) Country of Origin : China

10)Standard: AISI, ASTM29, DIN16723, EN10130, JIS, GB

11)Grade: SPCC, SPCD, SPCE, SPCH, ST12-15, DC01-06, Q195A-Q235A

12)Width: 30-1250mm (general width: 100mm, 610mm, 1200mm)

Application:

1.For the further producing of hot dip galvanized steel products

2.Auto manufacture, Oil drum, Transformer's tank panel, Furniture etc.

Others

1.Packing: Strapped with min three strapping strips, covered by anti-water paper and plastic film, fixed on the iron or wooden pallets by strapping strips and covered by plastic bag to prevent damage from

2. Payment term: L/C, T/T

3. Delivery date: 15-30 days

- Q: How are steel coils protected against scratches and damage?

- Steel coils are protected against scratches and damage through various methods such as applying protective coatings, using edge protectors, securely packaging them with appropriate materials, and ensuring careful handling during transportation and storage.

- Q: Does anyone know anything about Kodiak Steel Homes?

- Steel framing replaces all the wood making the house stronger and resistant to termites. Costs about $2,000 more per house and there is a lack of trained framers in most cities. Never heard of Kodiak brand. Do you know a city where they are located?

- Q: Can steel coils be customized in terms of size and shape?

- Yes, steel coils can be customized in terms of both size and shape to meet specific requirements and applications.

- Q: I want to start getting throwing knives and i was wondering what material is best for quality, but still cheap. I also saw some 440 stainless steel knives that i liked and wanted to know if the material was good

- For throwing knives, 440 isn’t necessarily a bad choice. Does it list whether it is 440c or 440b? That matters somewhat. The advantages of 440 Stainless is that it’s relatively hard (for a stainless), it resists rust significantly, and it’s not so hard that it would shatter or break. On the down side 440 is notorious for not taking or holding an edge, but for a throwing knife, that’s probably not much of an issue. If you’re looking for something to train with, you’re fine here. It’s plenty of steel enough to stick in wood or other targets. Odds are it won't bend if you slam it into some wood. If it lands on concrete, eh, it's going to scratch and all that jazz, and it might hurt the tip if it hits first, but as has been said, you can use a file or grinder to get the tip back.

- Q: What are the common methods of testing the strength of steel coils?

- Steel coils can be tested for strength using various methods. Tensile testing is one such method, which involves applying tension to the coil until it breaks. This test provides information about the coil's ability to withstand force and its tensile strength. It also reveals details about its yield strength and elongation properties. Another common method is hardness testing, which determines the steel's resistance to indentation or scratching. Different techniques like Rockwell, Brinell, or Vickers tests are utilized to measure hardness. This test helps determine the steel's ability to resist wear or deformation. To evaluate the coil's ductility and flexibility, bend testing is performed. The coil is bent to a specific angle and checked for any signs of cracking or fracturing. Bend testing assesses the material's capacity to withstand bending or forming procedures without failure. Additional methods of testing include impact testing, where controlled impacts are applied to assess the coil's resistance to sudden loading conditions, and fatigue testing, which involves subjecting the coil to cyclic loading to determine its endurance limit and potential for failure under repeated stress. It is important to note that the specific testing methods used may vary depending on the intended application and industry standards. Non-destructive testing techniques, such as ultrasonic testing or magnetic particle inspection, can also be employed to detect internal defects or flaws in steel coils without causing any damage.

- Q: How are steel coils processed for galvanizing or coating?

- Steel coils are processed for galvanizing or coating through a series of steps. First, the coils are cleaned to remove any dirt or oil. Then, they go through a chemical treatment to prepare the surface for coating. After that, the coils are coated with a layer of zinc or another protective material. Finally, the coated coils are cured or heated to ensure proper bonding and adhesion of the coating.

- Q: Can steel coils be stretched?

- No, steel coils cannot be stretched as they are already tightly wound and have limited flexibility.

- Q: Can steel coils be used in the production of packaging materials?

- Certainly, packaging materials can indeed utilize steel coils. Frequently, steel coils serve as the primary material in packaging items like metal strapping and steel banding. These coils possess remarkable strength, durability, and exceptional tensile strength, rendering them perfectly suitable for effectively securing and safeguarding diverse products throughout their transportation and storage. Furthermore, steel coils can be effortlessly molded and fashioned into various packaging elements, guaranteeing a dependable and secure packaging solution for an extensive array of industries.

- Q: How do steel coils contribute to the construction equipment industry?

- Steel coils play a crucial role in the construction equipment industry by providing the necessary raw material for manufacturing various construction machinery and equipment. These coils, made from high-quality steel, are used in the fabrication of a wide range of construction equipment, such as cranes, bulldozers, excavators, loaders, and forklifts. The primary contribution of steel coils to the construction equipment industry lies in their structural strength and durability. Steel is known for its excellent mechanical properties, including high tensile strength, toughness, and resistance to wear and corrosion. These qualities make it an ideal material for constructing heavy-duty machinery that can withstand the demanding conditions of construction sites. Steel coils are used to manufacture the structural components of construction equipment, such as chassis, frames, booms, buckets, and attachments. These components need to be robust and able to withstand heavy loads, impacts, and constant use. Steel coils provide the necessary strength and reliability to ensure the longevity and performance of construction equipment. Furthermore, steel coils are also used to fabricate specialized parts and accessories for construction machinery. These include hydraulic systems, gears, shafts, bearings, and fasteners. These components are crucial for the proper functioning and efficiency of construction equipment, and steel coils provide the high-quality material needed to manufacture them. In addition to their mechanical properties, steel coils also contribute to the construction equipment industry through their versatility and customization options. Steel can be easily shaped, cut, welded, and formed into various shapes and sizes, allowing manufacturers to create equipment with specific designs and functionalities to meet the diverse needs of construction projects. Overall, steel coils are indispensable in the construction equipment industry as they provide the foundation for robust and reliable machinery. Their strength, durability, and versatility make them an essential raw material for manufacturing construction equipment that can withstand the rigors of the construction site and ensure the safety and efficiency of construction projects.

- Q: How are steel coils used in the production of storage tanks and silos?

- Steel coils are used in the production of storage tanks and silos as they provide the necessary structural strength and durability required for these storage structures. The coils are formed, cut, and welded into the desired shape to create the walls and roofs of the tanks and silos. This ensures that the storage vessels can withstand the weight of the stored materials and any external forces exerted on them.

Send your message to us

Steel Coil or Sheet Cold Rolled of JIS G3141-1996, EN 10131-2006, DIN EN 1002

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords