Standard: DIN

Grade: DX51D+Z to DX57D

Type: Steel Coil

Surface Treatment: Galvanized

Application: Super deep drawing

Width: 600-1534mm

Length: Coil

Steel ASTM A755 (A653) - PrePainted Hot-Dip Galvanized Steel Coil CNBM

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

1.Quick Details:

2.Packaging & Delivery

| Packaging Details: | standard package |

|---|---|

| Delivery Detail: | 1-4 week |

cold rolled galvanizing steel coil

galvanized iron steel coil

4.Specifications

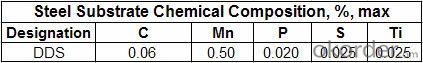

Steel Substrate Chemical Composition

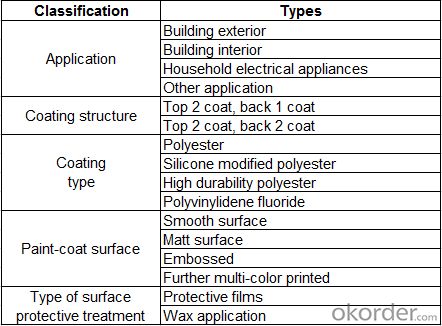

Classification

5.What is the application of Steel Coil?

There are two sides,one is out side: Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth;the other is inside: Door, doorcase, light steel roof structure, folding screen, elevator, stairway, vent gutter.

- Q: Are steel coils used in the packaging industry?

- Yes, steel coils are commonly used in the packaging industry for various applications such as strapping, bundling, and securing heavy loads.

- Q: I'm looking for a steel plate for an design project that requires neodymium magnets to be stuck on them. I am trying to figure out what kind of steel plate would have hold the magnets up the best.

- Magnet

- Q: I'm trying to buy a Survival,tactical knife but don't know what steel is better

- This Site Might Help You. RE: Whats better chrome vanadium steel or carbon stainless steel? I'm trying to buy a Survival,tactical knife but don't know what steel is better

- Q: How do steel coils contribute to the marine industry?

- The marine industry heavily relies on steel coils due to their multiple uses that contribute to the advancement, upkeep, and effectiveness of marine vessels. Initially, steel coils are crucial in ship and offshore platform construction. Their exceptional strength and durability make them ideal for the hull structure, ensuring the vessel's integrity and safety, even in harsh marine conditions. Furthermore, steel coils find application in the production of various marine equipment and parts. For example, they are utilized in the manufacturing of propellers, shafts, and rudders, which are vital for steering and propelling ships. By using steel coils in these components, their ability to withstand the corrosive impact of seawater is ensured, thereby prolonging their lifespan and reducing maintenance expenses. Moreover, steel coils play a significant role in the fabrication of marine pipelines and infrastructure for oil rigs. These coils are transformed into pipes and tubes that are essential for transporting oil, gas, and other fluids. The strength and corrosion resistance of steel coils are crucial in guaranteeing the dependability and safety of these pipelines, as they must endure extreme pressure and exposure to saltwater. Additionally, steel coils are also involved in the maintenance and repair processes of the marine industry. Whenever a ship undergoes renovations or repairs, damaged or corroded sections are often replaced with steel coils. The versatility of steel coils enables them to be molded and welded into various shapes and sizes, making them suitable for diverse repair applications. Overall, steel coils make a substantial contribution to the marine industry by providing the necessary strength, durability, and corrosion resistance required for the construction, maintenance, and efficiency of marine vessels. Their utilization in shipbuilding, component fabrication, pipeline construction, and repair procedures renders them indispensable for the growth and sustainability of the marine industry.

- Q: How are steel coils processed for different levels of hardness?

- Steel coils can be processed to achieve different levels of hardness through a variety of methods. One common method is heat treatment, which involves heating the coils to a specific temperature and then rapidly cooling them to alter their microstructure and achieve the desired hardness. The process of heat treatment can include quenching, tempering, or annealing, depending on the desired hardness level. Quenching involves cooling the coils rapidly in a liquid medium such as water or oil to achieve a high hardness level. Tempering, on the other hand, involves reheating the coils to a lower temperature and then slowly cooling them to achieve a desired balance of hardness and toughness. Annealing is a process that involves heating the coils to a specific temperature and then slowly cooling them to relieve internal stresses and achieve a softer and more ductile material. Additionally, mechanical processes such as cold rolling or cold working can also be used to increase the hardness of steel coils. These processes involve subjecting the coils to compressive forces, which cause the material to deform and result in an increase in hardness. Overall, the processing of steel coils for different levels of hardness requires careful control of temperature, cooling rate, and mechanical forces to achieve the desired properties for specific applications.

- Q: What are the common coil slitting methods?

- The common coil slitting methods include rotary shear, loop slitting, and double knife slitting.

- Q: What are the common coil lengths available for steel coils?

- The steel coil lengths offered in the industry and specific requirements are subject to variation. Nonetheless, several standard coil lengths are extensively employed in different applications. These encompass coil lengths of 100 feet (30.48 meters), 200 feet (60.96 meters), 300 feet (91.44 meters), and 500 feet (152.4 meters). These lengths find extensive use in construction, manufacturing, and automotive sectors, where steel coils serve diverse purposes. It is worth mentioning that coil lengths can also be tailored to meet specific project requirements or customer preferences.

- Q: What are the factors that affect the price of steel coils?

- The factors that affect the price of steel coils include supply and demand dynamics, fluctuations in raw material costs (such as iron ore and coal), changes in energy prices, market competition, import and export regulations, currency exchange rates, and overall economic conditions.

- Q: How are steel coils used in the manufacturing of seat structures?

- Steel coils are used in the manufacturing of seat structures by being shaped and molded to create the framework and support system of the seats. The coils provide strength and stability to the structure, ensuring durability and comfort for the users.

- Q: Are steel coils used in shipbuilding?

- Yes, steel coils are commonly used in shipbuilding. They are primarily used to manufacture various structural components and hull sections of ships due to their strength, durability, and resistance to corrosion.

Send your message to us

Steel ASTM A755 (A653) - PrePainted Hot-Dip Galvanized Steel Coil CNBM

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords