Quick Details

Standard: ASTM

Grade: FS Types A

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Forming Use

Width: 750-1534mm

Length: Coil

Packaging & Delivery

Packaging Details: Oscillated wound: one coil per bundle, inner is the protecting humidity-proof wax paper. Medium is plastic film. Outer is sackcloth or compound paper packing. Coil to be laid on single type pallet (one pile per pallet) Delivery Detail: 25 days but also depends on the quantity and specifications. Specifications

1. Top 2 coat: primer 5uM, top coat 15-20uM.

2. Back 2 coat: primer 2-5uM, back coat 5-20uM.

3. Back 1 coat: back coat 5-10uM.Grade FS(A) ASTM A755 (A653) - PrePainted Hot-Dip Galvanized Steel Coil

(1) Top 2 coat, back 1 or 2 coat

(2) RAL international color, With/Without temporary protective film(3) Coil ID: 508/610mm, Coil weight: 3-8Ton

(4) Steel Substrate Grade FS(A): Forming steel

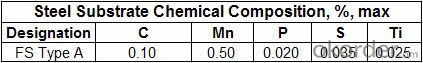

Steel Substrate Chemical Composition

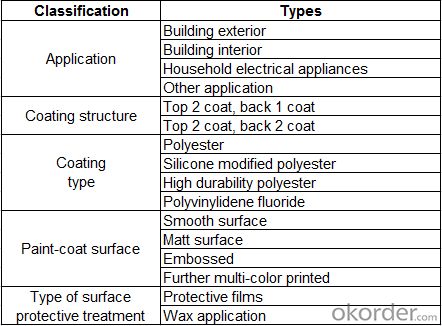

Classification