Valve with Competitive Price from 60year Old Valve Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Gate Valve Description:

A gate valve, also known as a sluice valve, is a valve that opens by lifting a round or rectangular gate/wedge out of the path of the fluid. The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry. For extremely thick fluids, a specialty valve often known as a knife valve is used to cut through the liquid. On opening the gate valve, the flow path is enlarged in a highly nonlinear manner with respect to percent of opening. This means that flow rate does not change evenly with stem travel. Also, a partially open gate disk tends to vibrate from the fluid flow. Most of the flow change occurs near shutoff with a relatively high fluid velocity causing disk and seat wear and eventual leakage if used to regulate flow. Typical gate valves are designed to be fully opened or closed.When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low friction loss.

2. Main Features of the Gate Valve:

• Valve body cavity using non-toxic epoxy resin,both inside and outside flashboard completely is coated with rubber

• Free of water pollution

• High manufacturing accuracy

• High strength

• Environmental protection and energy saving

• Good visual effect

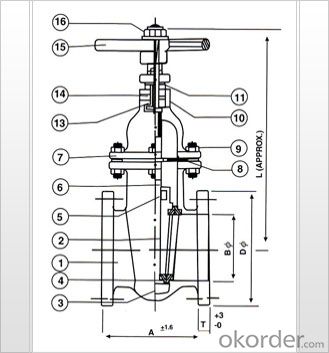

3. Images

4. Gate valve Specification

5.FAQ

1. What's are the characteristics of gate valve?

The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel.

2. What is the work principle of gate valve ?

The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry.

3. What is the structure?

Bonnets provide leakproof closure for the valve body. Gate valves may have a screw-in, union, or bolted bonnet. Screw-in bonnet is the simplest, offering a durable, pressure-tight seal. Union bonnet is suitable for applications requiring frequent inspection and cleaning. It also gives the body added strength. Bolted bonnet is used for larger valves and higher pressure applications.

- Q: Is the valve clockwise?

- The valve that can rotate is the principle of screw and nut. We can see that the switch is also buckled, so it is counterclockwise, the net is rotated out, clockwise downward, so it is off.

- Q: What does the valve stroke mean?

- Valve stroke is the distance from one position to another. Usually in the first position of the cut position, the second position is put through the position. Unless the valve has 3 positions.

- Q: the valve to an electrical signal, with this signal to control other components, ask: what valve?

- Online search "air switch", many suppliers.You may choose your pipe according to your pipe diameter.The flow meter can also be used to control the flow of operation

- Q: such as gate valve, three way plug valve

- The lower part of the pressure gauge installed water pipe, there are water, avoid high temperature, medium pressure gauge contact directly cause damage, so regular cleaning, in order to avoid congestion, three way plug function is used for flushing, please see "how to operate them.".

- Q: 1/2, what does 1/4 valve mean? I don't understand. What does this number mean? Have a valve to introduce me, do not copy a pile of online introduction, I want to concise

- Valve international universal caliber national nominal diameter1/4 inches, =2/8 inches, =2 minutes, =DN8 (mm)3/8 inches =3 points =DN10 (mm)1/2 inches, =4/8 inches, =4 minutes, =DN15 (mm)3/4 inches, =6/8 inches, =6 minutes, =DN20 (mm)1 inches =DN25 (mm)1 1/4 inch =DN32 (mm)1 1/2 inch =DN40 (mm)2 inches =DN50 (mm)

- Q: What does the RF of the valve mean?

- The flange flange can be applied to the HG/T flange standard, or any other flange standard. HG/T will be more detailed

- Q: Which valves are used in the power station?

- Power gate valve, also known as power station valve, is mainly used in various pipelines of fire power plants, cutting off or connecting pipeline medium.Applicable medium: non corrosive media such as water and steam. Compared with other valve products, the valve is characterized by high temperature and high pressure and unique self sealing design. The higher the pressure, the more reliable the seal is. Because of its performance, technical characteristics and special working conditions, the products can not be replaced by other products.Compared with other valve products, the gate valve of the power station is characterized by high temperature and high pressure. If only the pressure is lower than that of the universal valve, the temperature is lower than that of the general valve. Because of its performance, technical characteristics and special working conditions, the products can not be replaced by other products.

- Q: What are the technical requirements of valves, such as "Z15W-25T"?

- Z = gate valve1 = internal thread connection5 = dark rod type (structural form)W = body seal payments25 = 2.5MPa (nominal pressure)T = copper (body material)Landlord can refer to JB/T 308-2004 valve model preparation methods

- Q: What are mine valves?

- You want to see what works on the use of what media, in the choice of what type of valve is more appropriate. Shanghai HuquanValve manufacturers, veteran enterprises, trustworthy.

- Q: How big valves are used in a DN159 pipe?

- DN159 is the valve with the DN150 in the outer diameter of the pipe.

Send your message to us

Valve with Competitive Price from 60year Old Valve Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords