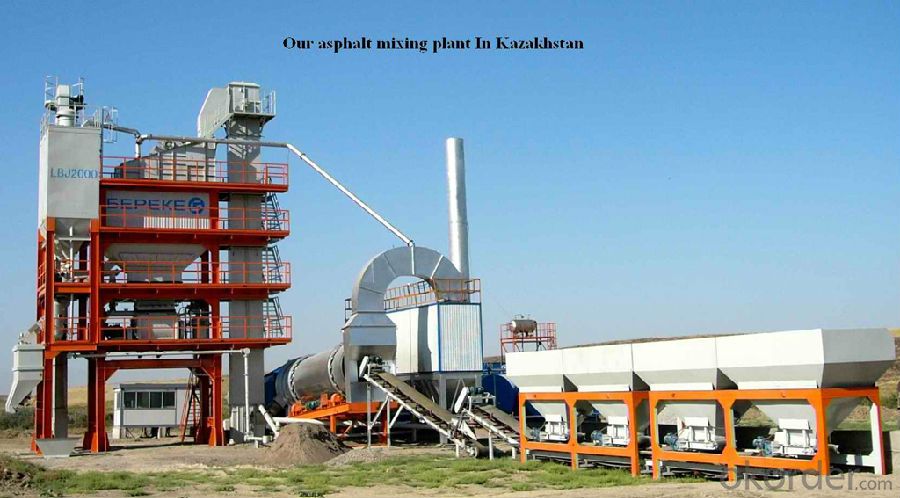

Asphalt Batching Plant with productivity of 160t/h

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification of asphalt&bitumen mixing plant LB2000

| Item | Technical data | ||

| Aggregate supply system (primary batching device ) | Hopper wall vibrator (2 units) | Motor power | 0.25KW |

| Collecting Conveyor belt | Belt width | 650MM | |

| Productivity | 200T/H | ||

| Motor power | 4 KW | ||

| Drying drum | Dimension | 2.3 X 8.2M | |

| Materials | Steel plate 16/20g | ||

| Installation angle | 5o | ||

| Drying drum drive motor | 4 X 15 KW | ||

| Drying drum rotational speed | 7.7RPM | ||

| Burning system | Imported oil burner (Optional) | Atomizing medium (optional) | |

| Model | ZZR2000 (Canada Digi Burner) | ||

| Power of blower | 15KW | ||

| Power of oil pump | 2.2KW | ||

| Screw air compressor | 22KW X 1 | ||

| Gas consumption | 3M3/MIN | ||

| Air pressure | 0.6MPa | ||

| Heavy oil tank | 10T(with oil duct) | ||

| Diesel tank | 10T(with oil duct) | ||

| Fuel Type | diesel oil, heavy oil and residual oil | ||

| Atomizing machinery (optional) | |||

| Model | EB8N (Italy Burner) | ||

| Composition | Blower oil,pump,console etc. | ||

| Heavy oil tank | 10T(with oil supplying pipeline) | ||

| Diesel tank | 10T(with oil supplying pipeline) | ||

| Bag dust collector (Optional) | Bag material | NOMEX weight 500g/m2,removing dust easily | |

| Dust collecting area | 670M3 | ||

| Air volume | 55000M3/H | ||

| Compressed air consumption | 2.6M3/MIN | ||

| Compressed air pressur | 0.4~0.7Mpa | ||

| Normal working temperature | 100175 | ||

| Instantaneous max heatresisting | 230 | ||

| Air compressors | Type | LB150320 | |

| Motor power | 11KW X 2 | ||

| Air consumption | 1.67M3/MIN | ||

| Gas storage tank | 0.6M3 | ||

| Dust recycling system | Hanging style rotation loader power | 0.75KW | |

| screw conveyer powert | 4KW | ||

| Inside spin power | 4KW | ||

| Recycle powder hoist | 4KW | ||

| draught fan | Fan motor power | 110KW | |

| fan wind air volume | 36762~69347M3/H | ||

| fan wind pressure | 28243874Pa | ||

| Auxiliary draught fan | Fan motor power | 3kw | |

| fan wind air volume | 3456~69347M3/H | ||

| fan wind pressure | 9171210Pa | ||

| The chimney | Height | 15M | |

| Exit dust exhaust concentration | <100mg/Nm3 | ||

| Vibrating screen | Vibration frequency | 19Hz | |

| Amplitude | 6~8MM | ||

| Screen areas | 18.6 M2 | ||

| Production capacity | ≥200T/H | ||

| Drive motor power | 11KW | ||

| Screen mesh specification | 35X35,22X22,11X11,6X6MM | ||

| Hot aggregate elevator | Type | duplex chain hopper | |

| Chain form | double chain ,automatic tensioner | ||

| Electromagnetic brake motor reducer | Power | 18.5KW | |

| Chain speed | 1.2M/S | ||

| Speed reducer power | 15KW | ||

| Height | 14.8M | ||

| Hoisting capacity | 200T/H | ||

| Hot aggregate bin | Type | 4 compartment hoppers | |

| Hopper volume | 36.7M3 | ||

| Weighing system | Hot aggregate scale hopper | volume | 2.1 M3 |

| Static measuring precision | ±0.5% | ||

| Weighting modularity sensor | HM-E-A-2 (Meidiya) | ||

| Powder weighing hopper | volume | 0.41M3 | |

| Static measuring precision | ±0.25% | ||

| Weighting modularity sensor | HM-E-A-0.3 (Meidiya) | ||

| Powder screw conveyer | LSL273×3020×4 | ||

| Screw conveyer power | 4KW | ||

| Asphalt weighing hopper | volume | 0.3M3 | |

| Static measuring precision | ±0.25% | ||

| modularity sensor | HM-E-A-0.2 (Meidiya) | ||

| The asphalt measuring pump | 7.5kw | ||

| The asphalt spraying pump | 11kW | ||

| Tower frame | Dimension | 8800*2250*2500 | |

| The mixer | Type | Two horizontal forced paddle type mixer | |

| Volume | 2000kg /batch | ||

| Cycle time | 45s | ||

| Drive motor power | 37KW×2 | ||

| Monitor room | Overall dimension | 5M X 2 M X 2.5 M | |

- Q: What kind of sand do you need for a concrete plant? I don't know where to start!

- Give you a website to see. Specializing in concrete mixing stations. Hope that useful.

- Q: What are the supporting facilities for the concrete mixing stations?

- The facilities include concrete mixing equipment, concrete transportation equipment, experimental equipment, forklift truck, over-pound equipment, pump, and car pump etc. Concrete mixing station is mainly composed of mixing console, materials weighing system, material conveying system, material storage system and control system of large system and other ancillary facilities. Because building aggregate measurement compared with standing aggregate metering, reduced the four of the intermediate links, and the vertical blanking metering, saved measuring time, thus greatly improving the production efficiency, under the condition of the same model, mixing building production efficiency than mixing plant production efficiency by a third. Such as: HLS90 floor of production efficiency and production efficiency of HZS120 stand HLS120 floor of the production efficiency, production efficiency is equivalent to HZS180 stand HLS180 floor of the production efficiency is equivalent to the productivity of HZS240 station. Concrete mixers are a combination of concrete and concrete prefabrication. Because its mechanization, high degree of automation, productivity is high, and can guarantee the quality of concrete and cement, commonly used in concrete, long duration and site of quantities focus of large and medium-sized water conservancy, electric power, Bridges and other projects. Centralized with the development of municipal construction, stirring, provide commercial concrete mixing station has great advantages, and thus get rapid development, and to promote concrete pumping construction, the mixing, transportation, casting machinery joint operation to create the conditions.

- Q: What constitutes the js750 concrete mixing station

- pecific configuration can be cut can be numerous js750 hosts are commonly used to climb a pipe loading, the concrete quality requirement is not high do not need automatic batching only buy a belt bucket host to climb to go, with a tractor modified small forklift about yao to climb add material in the bucket.

- Q: What does HZS mean in the HZS120 concrete mixing station

- Because building aggregate measurement compared with standing aggregate metering, reduced the four of the intermediate links, and the vertical blanking metering, saved measuring time, thus greatly improving the production efficiency, under the condition of the same model, mixing building production efficiency than mixing plant production efficiency by a third. Such as: HLS90 floor of production efficiency and production efficiency of HZS120 stand HLS120 floor of production efficiency, production efficiency is equivalent to HZS180 stand HLS180 floor of the production efficiency is equivalent to the productivity of HZS240 station.

- Q: How long does it take to build a concrete mixer station?

- The main idea is that the goods are completely incomplete, and the crane, the manpower, the mechanical tools. If everything is in place, then the pure installation will be two weeks to a month. Of course, also see you buy what type of product, container type is compared commonly faster, smaller and faster, under 3000 type slightly faster, 4000 and 5000 slowly

- Q: Classification of concrete mixing stations

- Commercial concrete mixing station: single/double HZS90 concrete mixing station, single/double hzss120 concrete mixing station, single/double hzss240 concrete mixing station, single/double hzss240 concrete mixing station. Engineering concrete mixing station: HZS75 concrete mixing station, HZS60 concrete mixing station, HZS50 concrete mixing station, HZS35 concrete mixing station, HZS25 concrete mixing station. Mobile concrete mixer station

- Q: What are the facilities of the concrete mixing station

- The concrete mixing station consists mainly of five major systems, such as mixing main, material conveying system, material weighing system, material storage system and control system

- Q: What are the advantages of HZS series of concrete mixing stations

- Concrete mixing plant is composed of ingredients, mixing and electric control system components made sets of fully automatic concrete mixing equipment, and equipped with a separate manual control, automatic fall compensation, sand moisture content of compensation, can automatically accomplish the tank production. The theory of productivity 75 cubic meters/hour, discharging height is 3.8 meters, the storage hopper volume of 8 cubic * 3 warehouse or 4 warehouse, supporting the host is forced JS1500 type and double shaft mixer

- Q: How much concrete is produced by the js1000 type of the concrete mixing station

- According to the national standard, 1 cubic host is the JS1000, the general theoretical productivity of the standard test concrete is not less than 50 cubic meters per hour. But the actual situation is fully automatic, normally can be above 40 cubic meters. The cement productivity would be low by hand.

- Q: What is the special work of the concrete mixing station

- The ratio of the concrete particles to the surface area, the shape of particles, the density of the particles and the grading of the particles, etc., are very important to the liquidity of the slurry. Smaller than surface area, the particle shape is closer to the ball, bigger, more filling and more liquid. By optimizing these factors, you can obtain the most appropriate liquidity. In order to design the concrete mix according to the engineering requirement, the characteristics of the aggregate material must be mastered first. The properties of aggregates are determined by factors such as microstructure, prior exposure and processing, and these factors influence the properties of fresh and hardened concrete. The effect of aggregate properties on concrete performance should be considered, and the quality of concrete mixing equipment should be considered. Before installation, check the appearance quality of the equipment again, the platform bolts are not loose, the welding seam is not cracked, the oil leak, the water, the ash (the lump), etc. Clean the assembly of the whole machine and re-spray paint, rust and renovate. Prepare the all kinds of bolts, welding wire, iron plate, etc., to prepare tools and protective equipment, the use of more tools for several sets of parts can use pneumatic wrench, and provide timely acetylene cutting, electric welding equipment; Plan the entry time of the crane.

Send your message to us

Asphalt Batching Plant with productivity of 160t/h

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords