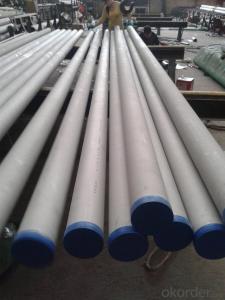

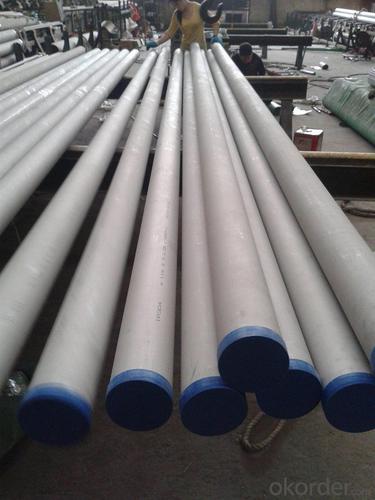

Stainless steel tube; high quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | JIS,AISI,ASTM,GB,DIN,CE | Place of Origin: | Guangdong China (Mainland) | Brand Name: | QX |

| Model Number: | 201/202/304/316/316L/430 | Type: | Welded | Steel Grade: | 300 Series |

| Application: | Decoration,construction, upholstery | Certification: | ISO | Welding Line Type: | ERW |

| Thickness: | 0.3mm to 3.0mm | Outer Diameter: | 9.53mm to 159mm | Polish: | Satin,Bright or Mirror |

| Grade: | 201,202,301,304,316,316l,430 ect. | Length: | In gernal 5.8m/6m or as customer request | Process method: | Hot rolled |

| Test: | Squash test, water pressure test,extended test,crystal rot test etc. | Production Standard: | ASTM A554 | Materials: | SUS 304, 201, 316, 316L,430 ect |

| OD tolerance: | + / - 0.15mm | Thickness tolerance: | +/- 10% | Length tolerance: | +/- 10mm |

Packaging & Delivery

| Packaging Detail: | Every tube is sleeved in plastic bag individually, and then several tubes are packed by weaving bag, which is seaworthy. Or 50kg/bundle, 500kg/bundle.We can pack as clients' requirement. |

| Delivery Detail: | 25 - 35 days for a full container. |

Specifications

Stainless Steel Pipe:

1.201,202,301,304,316L,430,etc

2.OD:6mm-159mm

3.Thickness:0.25mm-3.5mm

4.Finish:Mirror,Satin,Hairline

- Q: Are stainless steel pipes suitable for water desalination plants?

- Yes, stainless steel pipes are suitable for water desalination plants. Stainless steel is highly resistant to corrosion, making it an ideal material choice for handling the high salinity levels in desalination plants. It offers excellent durability, longevity, and reliability in harsh environments, ensuring the efficient and safe transportation of water throughout the plant.

- Q: Can stainless steel pipes be used in the agriculture industry?

- Yes, stainless steel pipes can be used in the agriculture industry. Stainless steel pipes are highly resistant to corrosion, making them ideal for agricultural applications where exposure to moisture, chemicals, and other corrosive substances is common. They are commonly used for irrigation systems, water supply lines, and various agricultural processes that require durable and long-lasting piping solutions. Additionally, stainless steel pipes are hygienic, easy to clean, and can withstand high temperatures, making them suitable for agricultural processes that involve food production and processing.

- Q: What does "stainless steel pipe" DN mean?

- Nominal diameter is the size of all piping accessories in the piping system. The nominal diameter is a convenient round integer for reference and is not strictly related to the processing size. The nominal diameter follows the letter "DN" followed by a number sign.

- Q: Can stainless steel pipes be used for oil and gas refineries?

- Yes, stainless steel pipes can be used for oil and gas refineries. Stainless steel offers excellent corrosion resistance, high strength, and durability, making it suitable for handling various corrosive fluids and gases in the refining process. Additionally, stainless steel pipes can withstand high temperatures and pressures, ensuring the safe and efficient transportation of oil and gas in refineries.

- Q: How is stainless steel pipe different from carbon steel pipe?

- Stainless steel pipe and carbon steel pipe differ mainly in their composition and corrosion resistance properties. Stainless steel pipe contains a higher percentage of chromium, which forms a passive oxide layer on its surface, making it highly resistant to corrosion and oxidation. On the other hand, carbon steel pipe does not have this protective layer, making it more prone to rust and corrosion. Additionally, stainless steel pipe is generally more expensive than carbon steel pipe due to its superior corrosion resistance and durability.

- Q: What is the density of stainless steel pipes?

- The density of stainless steel pipes can vary depending on the specific grade of stainless steel used. However, the typical density range for stainless steel pipes is between 7.9 to 8.0 grams per cubic centimeter (g/cm³). This density is relatively high compared to other materials, which contributes to the strength and durability of stainless steel pipes.

- Q: How can the stainless steel tube eliminate stress?

- Or artificial stress, method: stresses both ends of the steel pipe fixed by the mold, through high-frequency shocks, so that the internal stress relief of the steel pipe

- Q: How do stainless steel pipes compare to PEX pipes?

- Different plumbing systems require different characteristics and applications, making stainless steel pipes and PEX pipes suitable options. Stainless steel pipes are renowned for their durability and strength, making them ideal for water supply systems, especially in areas with aggressive water conditions. Their resistance to corrosion and ability to withstand high pressure and temperature make them suitable for both residential and commercial use. Moreover, stainless steel pipes are fire-resistant and have a long lifespan, requiring minimal maintenance and offering cost-effectiveness in the long term. On the other hand, PEX pipes, composed of cross-linked polyethylene, provide flexibility and easy installation. These pipes are highly resistant to freezing and bursting, making them a great choice for cold-climate regions. Their capacity to expand and contract reduces the risk of leaks or bursts caused by temperature changes. Additionally, PEX pipes are corrosion-resistant, eliminating the need for costly and time-consuming maintenance. They also dampen noise and vibration, providing a quieter alternative to metal pipes. When making a decision between stainless steel pipes and PEX pipes, it is crucial to consider specific plumbing requirements, budget, and local building codes. While stainless steel pipes excel in durability and strength, PEX pipes offer flexibility and ease of installation. Ultimately, the choice depends on the unique needs of the plumbing system and the preferences of the homeowner or plumbing professional.

- Q: Can stainless steel pipes be insulated with fiberglass?

- Yes, stainless steel pipes can be insulated with fiberglass.

- Q: Can stainless steel pipes be used for heat exchangers?

- Indeed, heat exchangers can make use of stainless steel pipes. The reason behind the popularity of stainless steel for heat exchangers lies in its remarkable resistance to corrosion, ability to withstand high temperatures, and durability. Its capability to endure variations in pressure and temperature renders it appropriate for diverse heat exchange applications. Moreover, stainless steel pipes exhibit commendable thermal conductivity, enabling efficient heat transfer. Moreover, stainless steel proves to be a dependable and long-lasting choice for heat exchangers in numerous industries like chemical, pharmaceutical, food processing, and HVAC, owing to its ease of cleaning and maintenance.

Send your message to us

Stainless steel tube; high quality

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords