Stainless Steel Strip Hot Rolled Type Steel Coil

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Strip Hot Rolled Type Steel Coil

Main Structure of Steel Strip

1>Thk:0.1mm-50mm

2>Width:100mm-3000mm

3>Length:Coil

4>Surface:BA,2B,No.1,No.4,HL,8K etc

Specification of Steel Strip

Commodity | China good stainless steel strip/tape | ||

Description |

Steel Coil/Stainless Steel Coil/Hot Rolled and Cold Rolled Stainless Steel Coil | ||

Standard |

ASTM A240, JIS G4304, JIS G4305, EN10028 etc | ||

Series |

200 Series |

300 Series |

400 Series |

Material |

201,202 | 301,304,304L,TP304,TP304L,309S,310S, 316,316L,TP316,TP316L,317L,321,347, TP321,TP347,321H,347H | 405,409,410,410S, 420,430 |

Thickness |

0.1mm-50mm | ||

Width |

1000mm,1219mm,1250mm,1500mm,1800mm,2000mm,2500mm,3000mm etc | ||

Length |

Coil or as demand | ||

Manufacture Type |

Hot Rolled, Cold Rolled | ||

Surface Treatment |

BA,2B,No.1,No.4,No.8,Hair Line,Mirror Finish,Embossed | ||

Packaging |

Wooden Case,Pallet Wooden,20'GP or 40'GP Container | ||

Application of Steel Strip

Stainless Steel Coil is widely used in Container,Shipping,Machine Manufacture,

Kitchen and Hardware Tools,Oil and Chemical Industry,Food and Medical Industry,

Agricultural and Light Industry,Surgical Knife etc

FAQ:

Q:How about your quality?

A:Quality is our culture, our products has to be checked with engineer, QC and sales, customer together, The products’ qualified rate need to be over 95%.

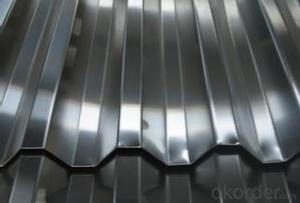

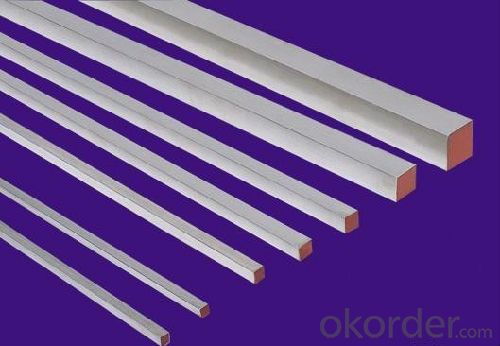

Pictures

- Q: im buying a new guitar,, it has a built in tuner and its semi acoustic (can be plugged into an amplifier) ,, im trying to choose which strings are better ,, steel or nylon..?

- i have steel and i like the way it sounds but i like nylon better

- Q: What is the maximum width of galvanized steel strip, please? The galvanized coat is 275, and how long is one coil?

- But this kind of steel coil is not well processed in the market. At the beginning of Wuhan, several processing plants are good at processing, and other processing plants usually process 1850 at most.

- Q: How are steel coils affected by global trade policies?

- Steel coils can be significantly affected by global trade policies. Trade policies, such as tariffs and quotas, can impact the import and export of steel coils, influencing their availability and pricing in different markets. Changes in trade policies can lead to shifts in supply and demand, affecting the volume and cost of steel coil imports and exports. Additionally, trade policies aimed at protecting domestic industries may create barriers for steel coil imports, potentially affecting the competitiveness of steel coil manufacturers and suppliers.

- Q: What are the different methods of shearing steel coils?

- There are several different methods of shearing steel coils, each offering its own unique advantages and disadvantages. Some of the most common methods include: 1. Guillotine Shearing: This method involves using a guillotine-like machine with a blade that moves vertically to cut through the steel coil. Guillotine shearing offers high efficiency and accuracy, making it suitable for large-scale industrial production. However, it may cause deformation or burrs on the cut edges. 2. Rotary Shearing: In rotary shearing, a set of rotating blades is used to cut through the steel coil. This method allows for continuous cutting, making it ideal for high-speed production lines. It provides a clean and precise cut, but it requires regular maintenance and sharpening of the blades. 3. Slitting: Slitting involves passing the steel coil through a set of circular blades that make multiple parallel cuts. This method is commonly used to produce narrower strips from wider coils. It offers high precision and can produce multiple strips simultaneously. However, slitting may cause edge burrs or camber on the strips. 4. Laser Cutting: Laser cutting uses a high-powered laser beam to melt or vaporize the steel coil along a pre-determined path. This method offers exceptional precision and can cut complex shapes or patterns. It is commonly used for specialized applications where accuracy is crucial, although it can be relatively expensive. 5. Waterjet Cutting: Waterjet cutting utilizes a high-pressure stream of water mixed with abrasive particles to cut through the steel coil. This method is versatile and can handle various materials and thicknesses. It is especially useful for cutting heat-sensitive materials or for applications requiring minimal distortion. 6. Plasma Cutting: Plasma cutting involves ionizing a gas to create a plasma arc that melts and blows away the steel coil. This method is fast and efficient, suitable for cutting thick steel coils. However, it may produce a wider heat-affected zone compared to other methods. 7. Electrical Discharge Machining (EDM): EDM uses electrical discharges to erode the steel coil and create the desired shape. This method is commonly used for intricate or delicate cutting tasks that require high precision. It is particularly effective for hard materials. Each method of shearing steel coils has its own set of advantages and limitations, and the choice depends on factors such as the required precision, speed, material thickness, and the desired end-product.

- Q: Classify the following in as many ways as possible:stainless steelpureheterogeneous mixturehomogeneous mixturenone of these

- homogeneous mixture

- Q: How are steel coils annealed to improve their properties?

- Steel coils are annealed by heating them to a specific temperature and then slowly cooling them, which allows for the recrystallization of the steel. This process helps to relieve internal stresses, improve the material's ductility, and enhance its overall mechanical properties.

- Q: How are steel coils inspected for surface defects?

- Steel coils are inspected for surface defects using various methods such as visual inspection, magnetic particle testing, eddy current testing, and ultrasonic testing. These techniques help identify any imperfections or flaws on the surface of the steel coils, ensuring they meet quality standards before they are further processed or shipped to customers.

- Q: I'm kind of confused as to how the difference between a stainless steel and blued steel firearm is sometimes only $20 or so. Isn't stainless steel fairly more expensive to manufacture than plain carbon steel? Are some stainless steel firearms simply stainless steel finished with carbon steel underneath?

- No, there are no rifles produced that are carbon steel underneath with a stainless steel finish. Typically, gun prices are set by whatever people will pay for the finished product, NOT based on what the material costs actually are. Even if the stainless were CHEAPER to produce, manufacturers could still charge a premium on those products because it offers an advantage to the user (less maintenance). Stainless is seen as an upgrade because of the maintenance and the good looks, so it's like an upgrade option on a sports car, even if it doesn't improve actual performance, it improves the marketability for the product, so it increases the product price. For rifle barrels, many manufactures do NOT charge a high mark up for stainless steel because even though YES is is harder to machine, they don't have to blue the part, which is an extra processing step, and extra materials cost. So when a stainless steel blank is made, it is machined, washed, and finished, but a chrome-moly barrel much be machined, washed, prep'd, hot blued, and finished.

- Q: How are steel coils used in the production of automotive suspension systems?

- Steel coils are used in the production of automotive suspension systems as they provide the necessary support and flexibility to absorb shocks and vibrations. These coils are typically used in the construction of coil springs, which are then integrated into the suspension system to ensure a smooth and comfortable ride for the vehicle.

- Q: What are the different types of steel coil surface finish treatments?

- There are several different types of steel coil surface finish treatments, including hot-dip galvanizing, electro-galvanizing, zinc plating, powder coating, and painting. These treatments are applied to steel coils to enhance their durability, corrosion resistance, and aesthetic appeal.

Send your message to us

Stainless Steel Strip Hot Rolled Type Steel Coil

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords