Stainless Steel Sheet AISI 420 with Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 45555555 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of stainless steel plate::

316L stainless steel containing molybdenum species, the steel containing molybdenum, the overall performance is better than steel 310 and 304 stainless steel, high temperature conditions.

Festures of stainless steel plate:

architectural decoration, luxury doors, elevators decorating, metal tank shell, ship building, decorated inside the train, as well as outdoor works, advertising nameplate, the ceiling and cabinets, aisle panels, screen, the tunnel project, hotels, guest houses, entertainment place,kitchen equipment,light industrial and others.

Specifications of stainless steel plate:

Product Name | cr 1219x2438 stanless steel sheet 201 |

standared | JIS, AISI, ASTM, GB, DIN,SUS |

Thickness | 0.2mm~2.5mm |

Size | 1000*2000mm,1219*2438mm or as per customers' request |

Surface finish | 2B, BA, Hair Line, No.1,No.4, Mirror Finish |

Application | product parts manufacturing and stainless steel products tooling and so on |

Payment terms | T/T 30% for deposit, Balance against the copy of B/L; or L/C at sight |

Product Packing | wooden pallet |

Delivery time | within 15-20 working days after we got your 30% deposit |

Attention | FREE SAMPLES can be sent on request. |

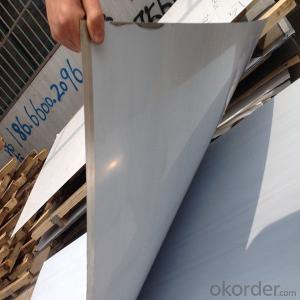

Images of stainless steel plate:

FAQ:

1. What is your package?

Packing situation: standard seaworthy packing or as customer required.

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: How is steel wire rod used in the production of wire mesh for industrial sieving?

- Steel wire rod is a crucial component in the production of wire mesh for industrial sieving. Wire mesh is commonly used in various industries, such as mining, construction, and agriculture, for the purpose of separating and classifying different materials based on their size and shape. The steel wire rod serves as the raw material for wire mesh production. It is first processed through a series of manufacturing steps to transform it into a suitable form for creating the mesh. The wire rod is typically drawn through a series of dies to reduce its diameter and increase its length. This process is known as wire drawing and results in a thin and elongated wire. Once the wire rod has been drawn, it is then woven or welded together to form the wire mesh. The weaving process involves interlacing the wires in a crisscross pattern, creating a strong and durable mesh structure. On the other hand, the welding process involves fusing the wires together at their intersections using heat or pressure, resulting in a solid and stable mesh. The choice between weaving and welding depends on the specific requirements of the application. Weaving is commonly used for producing wire mesh with smaller openings and finer mesh sizes, while welding is preferred for larger openings and heavier wire diameters. The wire mesh produced from steel wire rod offers several advantages for industrial sieving. Firstly, steel is a highly durable and robust material, capable of withstanding harsh environments and heavy loads. This ensures that the wire mesh can endure the constant impact of materials during the sieving process without losing its structural integrity. Additionally, steel wire rod provides excellent tensile strength, allowing the wire mesh to maintain its shape and resist deformation under tension. This is particularly important for applications that involve high-pressure sieving or require the mesh to be stretched tightly over a frame. Moreover, steel wire rod can be manufactured with different coatings or treatments to enhance its resistance to corrosion, abrasion, or other forms of wear and tear. This further extends the lifespan of the wire mesh, making it suitable for long-term industrial use. In summary, steel wire rod is an essential component in the production of wire mesh for industrial sieving. Its versatility, durability, and strength make it an ideal raw material for creating wire mesh that can withstand rigorous sieving applications in various industries.

- Q: How is steel wire rod used in the manufacturing of wire for thermal insulation?

- Steel wire rod is used in the manufacturing of wire for thermal insulation by being transformed into a thin wire through a series of processes such as drawing, annealing, and coating. This wire is then used to create the core of thermal insulation materials, which helps in providing structural strength and stability to the insulation. Additionally, the steel wire rod can also be used to create the outer protective layer of the insulation, enhancing its durability and resistance to external factors.

- Q: What are the different types of steel wire rod processing equipment?

- There are several different types of steel wire rod processing equipment used in the manufacturing and production process. These equipment are designed to perform various tasks and processes to transform raw steel wire rods into finished products. Some of the different types of steel wire rod processing equipment include: 1. Wire Drawing Machines: These machines are used to reduce the diameter of the wire rod by pulling it through a series of dies. This process helps to improve the surface finish, accuracy, and strength of the wire. 2. Wire Straightening and Cutting Machines: These machines are used to straighten and cut the wire rod into desired lengths. They can handle various wire diameters and are commonly used in the production of wire products such as nails, screws, and wire mesh. 3. Wire Annealing Furnaces: Annealing is a heat treatment process used to soften the wire rod and improve its ductility and machinability. Annealing furnaces provide controlled heating and cooling conditions to achieve the desired properties. 4. Wire Coiling Machines: Coiling machines are used to wind the straightened and cut wire rod into coils. They can be manual or automated, depending on the volume and size of the coils required. 5. Wire Galvanizing Lines: Galvanizing is a process in which a layer of zinc is applied to the surface of the wire rod to protect it from corrosion. Galvanizing lines are used to clean, flux, and coat the wire rod with molten zinc. 6. Wire Electroplating Equipment: Electroplating is a process in which a thin layer of metal is deposited onto the surface of the wire rod to enhance its appearance or provide specific properties. Electroplating equipment includes tanks, rectifiers, and various chemical solutions. 7. Wire Mesh Welding Machines: These machines are used to weld the wire rods together to create wire mesh products such as fences, reinforcement grids, and filter screens. They can be either manual or automated, depending on the complexity of the mesh design. 8. Wire Stranding Machines: Stranding machines are used to twist multiple wire rods together to form stranded cables. These machines are commonly used in the production of electrical cables and conductors. Overall, the different types of steel wire rod processing equipment play a crucial role in the manufacturing and production of various wire and steel products. They enable the transformation of raw materials into finished products with the desired properties and specifications.

- Q: What are the main factors influencing the choice of steel wire rod order storage tracking options?

- The main factors influencing the choice of steel wire rod order storage tracking options include the size and complexity of the inventory, the level of automation in the storage facility, the frequency of order retrieval and replenishment, the need for real-time visibility and accuracy in tracking, and the overall cost and efficiency of implementing different tracking systems.

- Q: How is steel wire rod used in the manufacturing of wire rope assemblies for mining applications?

- Steel wire rod is an essential element in the production of wire rope assemblies used in mining operations. These assemblies are utilized for lifting and transporting heavy loads, ensuring stability and support, and guaranteeing worker safety. To manufacture steel wire rod, the initial step involves melting steel scrap in a furnace and continuously casting the molten steel into billets or blooms. These billets are then hot rolled into long, slender rods with diameters ranging from a few millimeters to several centimeters. Once the steel wire rod is produced, it undergoes a series of processes to convert it into wire rope. Wire drawing is the first step, where the rod is pulled through a series of dies to reduce its diameter and increase its length. This process also enhances the wire's surface finish and mechanical properties. Following wire drawing, a lubricant is typically applied to the steel wire to reduce friction and enhance corrosion resistance. This lubricant also provides protection during subsequent manufacturing processes. Next, the wire is twisted together to form strands. The specific application and required strength of the wire rope assembly determine the number of strands and the design of the twist pattern. The strands are then helically laid around a central core, providing additional strength and support. Finally, the wire rope assembly undergoes a process called closing, where the entire length of the assembly is compressed to ensure tightness and secure holding of all the strands. This closing process also improves the overall structural integrity of the wire rope assembly. In mining applications, wire rope assemblies made from steel wire rod are employed in various ways. They are commonly used in hoisting systems for lifting heavy loads, including equipment, ore, and personnel. These assemblies also serve suspension and support purposes, providing stability to underground tunnels and shafts. Furthermore, wire rope assemblies are utilized in safety applications, such as fall protection systems and rescue operations. Overall, steel wire rod plays a vital role in manufacturing wire rope assemblies for mining applications. Its strength, durability, and flexibility make it an ideal material for withstanding the demanding conditions and heavy loads commonly encountered in the mining industry.

- Q: How is the steel wire rod market affected by mergers and acquisitions?

- The steel wire rod market can be significantly affected by mergers and acquisitions. When companies in the steel wire rod industry merge or acquire one another, it leads to consolidation within the market. This consolidation can have both positive and negative impacts on the overall market dynamics. One of the main effects of mergers and acquisitions in the steel wire rod market is the potential reduction in competition. When two or more companies merge, they combine their resources, production capabilities, and market share, resulting in a larger and more dominant player in the industry. This can lead to a decrease in competition, allowing the merged entity to exert more control over pricing and market conditions. On the positive side, mergers and acquisitions can also lead to economies of scale. By combining operations and streamlining processes, companies can achieve cost savings and improve efficiency. This can result in lower production costs, which may be passed on to customers in the form of lower prices. Additionally, the merged entity may have access to a broader customer base and distribution network, enabling them to reach new markets and increase market share. However, there are also potential drawbacks to mergers and acquisitions in the steel wire rod market. Consolidation may lead to job losses as duplicate positions are eliminated to achieve cost synergies. Furthermore, if the merged entity becomes too dominant in the market, it may have the ability to dictate terms to other market participants, potentially limiting choice and options for customers. Overall, the impact of mergers and acquisitions on the steel wire rod market depends on various factors such as the size and scope of the merger, the market structure, and the competitive landscape. While consolidation can lead to both positive and negative effects, it is essential for regulators to monitor and ensure fair competition in order to protect the interests of consumers and maintain a healthy market environment.

- Q: How is the corrosion resistance of steel wire rod evaluated?

- Various methods and tests are utilized to assess the corrosion resistance of steel wire rod. One commonly employed technique is the salt spray test, which is also known as the ASTM B117 test. During this test, the steel wire rod is exposed to a controlled environment of saltwater spray for a specific duration. Subsequently, the wire rod is inspected for any indications of corrosion, such as rust or discoloration. Another approach employed to evaluate corrosion resistance is the electrochemical test, such as the measurement of polarization curves. This test entails immersing the steel wire rod in an electrolyte solution and administering a small electric current. The resultant polarization curve provides information regarding the rate of corrosion and the propensity of the wire rod to corrode. Moreover, visual inspection and microscopic examination of the wire rod's surface can be conducted to identify any signs of corrosion, such as pitting or surface roughness. These evaluations are often supported by various corrosion measurement techniques, including analysis of weight loss, measurement of corrosion potential, and determination of corrosion rate. To summarize, the corrosion resistance of steel wire rod is evaluated through salt spray tests, electrochemical tests, visual inspection, and microscopic examination. These evaluations furnish valuable information about the wire rod's capacity to withstand corrosion and ensure its suitability for diverse applications.

- Q: How is steel wire rod used in the production of wire baskets?

- Steel wire rod is used in the production of wire baskets as it serves as the primary raw material for manufacturing the wire mesh used in the baskets. The steel wire rod is processed and transformed into wires of various thicknesses and lengths, which are then woven or welded together to create the mesh structure of the basket. This ensures the strength, durability, and stability of the wire basket, making it suitable for holding and organizing various items.

- Q: How is steel wire rod used in the manufacturing of pre-stressed concrete?

- Steel wire rod is an essential component in the manufacturing of pre-stressed concrete. Pre-stressed concrete is a type of concrete that has been reinforced with steel cables or bars to enhance its structural strength and durability. Steel wire rod is commonly used as the primary material for producing these steel cables or bars. In the manufacturing process, steel wire rods are first drawn through a series of dies to reduce their diameter and increase their tensile strength. This process, known as cold drawing, results in a smooth and consistent wire with a high strength-to-weight ratio. The wire rod is then wound into coils for easy handling and transportation. To create pre-stressed concrete, the steel wire rod is further processed into strands or individual wires. These strands or wires are then embedded into the concrete structure before it sets. The steel wires are tensioned using hydraulic jacks, applying a force that is greater than the anticipated load the concrete will experience during its service life. This tensioning process helps to counteract the tensile stresses that concrete naturally experiences, making it more resistant to cracking and deformation. By incorporating steel wire rods into pre-stressed concrete, the overall strength and durability of the structure are significantly improved. The steel wires act as a reinforcement, providing additional strength to the concrete and allowing it to withstand higher loads and resist cracking. This is particularly useful in applications such as bridges, buildings, and other infrastructure projects where the concrete needs to bear heavy loads or endure challenging environmental conditions. Furthermore, pre-stressed concrete structures are more cost-effective compared to traditional reinforced concrete. The use of steel wire rod reduces the need for additional reinforcement, such as steel bars, resulting in a lighter and more efficient structure. The reduced weight also facilitates faster construction and lower transportation costs. In conclusion, steel wire rod plays a crucial role in the manufacturing of pre-stressed concrete. It is used to create steel cables or bars that are embedded in the concrete structure, enhancing its strength, durability, and load-bearing capacity. By incorporating steel wire rods, pre-stressed concrete structures can withstand higher loads, resist cracking, and provide cost-effective solutions for various construction projects.

- Q: What are the common applications of cold heading quality steel wire rod?

- Cold heading quality steel wire rod is commonly used in the manufacturing industry for various applications such as producing bolts, screws, nuts, and other fasteners. It is also utilized in automotive parts, construction materials, and precision components where high strength and excellent cold forming characteristics are required.

Send your message to us

Stainless Steel Sheet AISI 420 with Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 45555555 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords