Stainless Steel Sheet AISI 316 with Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 45555555 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of stainless steel plate::

316L stainless steel containing molybdenum species, the steel containing molybdenum, the overall performance is better than steel 310 and 304 stainless steel, high temperature conditions.

Festures of stainless steel plate:

| Packaging Details: | standard packing to export 4 eye bands and 3 circumferential bands in steel, galvanized metal fluted rings on inner and outer edges |

| Delivery Detail: | 15-25 days after received your deposit or to your quantity |

Specifications of stainless steel plate:

Product Name | cr 1219x2438 stanless steel sheet 201 |

standared | JIS, AISI, ASTM, GB, DIN,SUS |

Thickness | 0.2mm~2.5mm |

Size | 1000*2000mm,1219*2438mm or as per customers' request |

Surface finish | 2B, BA, Hair Line, No.1,No.4, Mirror Finish |

Application | Kitchenware, decoration construction and building ornament, product parts manufacturing and stainless steel products tooling and so on |

Payment terms | T/T 30% for deposit, Balance against the copy of B/L; or L/C at sight |

Product Packing | wooden pallet |

Delivery time | within 15-20 working days after we got your 30% deposit |

Attention | FREE SAMPLES can be sent on request. |

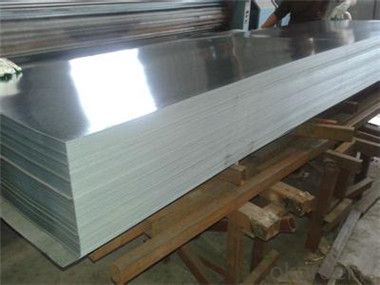

Images of stainless steel plate:

FAQ:

1. What is your package?

Packing situation: standard seaworthy packing or as customer required.

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: What are the trends in the steel wire rod market?

- The trends in the steel wire rod market include increasing demand from various industries such as construction, automotive, and manufacturing. Additionally, there is a growing focus on the development of high-quality and advanced steel wire rods to meet the evolving needs of these industries. Moreover, the market is witnessing a shift towards sustainability and the adoption of eco-friendly manufacturing processes in the steel wire rod production.

- Q: How is steel wire rod used in the production of wire ropes?

- Steel wire rod is used as the primary raw material in the production of wire ropes. It is drawn into smaller diameters and then twisted together to form strands. These strands are then further twisted or braided together to create the final wire rope. The high tensile strength and durability of steel wire rod make it suitable for withstanding heavy loads, making wire ropes crucial in various industries such as construction, mining, and transportation.

- Q: How is steel wire rod used in the production of electrical conductors?

- Steel wire rod is used in the production of electrical conductors as it serves as the core material for these conductors. The wire rod is typically drawn into a thinner and longer wire, which is then coated with a layer of insulating material. This coated wire is used to transmit electrical signals or power, as the steel core provides strength and durability while the insulating layer prevents electrical leakage. Overall, steel wire rod plays a crucial role in ensuring the efficient and reliable transmission of electricity through electrical conductors.

- Q: How is steel wire rod classified based on its chemical composition?

- Different grades or types are used to classify steel wire rod based on its chemical composition. The levels of carbon and alloying elements in the steel primarily determine this classification. Mild steel wire rod, also known as low carbon steel, typically contains a carbon content ranging from 0.05% to 0.25%. This type of steel is commonly used in general-purpose applications such as construction, automotive, and machinery. Wire rod made of medium carbon steel has a higher carbon content, usually between 0.25% and 0.60%. This grade of steel provides increased strength and hardness, making it suitable for applications that require higher tensile strength, like springs, wires, and cables. High carbon steel wire rod contains a carbon content of over 0.60%. This grade of steel is well-known for its exceptional strength and hardness. It is commonly used in the manufacturing of high-strength wires, guitar strings, and cutting tools. Alloy steel wire rod is composed of multiple alloying elements, including chromium, nickel, manganese, or molybdenum, in addition to carbon. These alloying elements enhance specific properties of the steel, such as corrosion resistance, heat resistance, or wear resistance. Alloy steel wire rod finds its applications in specialized fields like automotive components, fasteners, and machinery parts. To sum up, steel wire rod is classified based on its chemical composition. The varying levels of carbon and alloying elements determine its specific grade or type. This classification facilitates the selection of the appropriate steel wire rod for specific applications, taking into account the desired mechanical properties and performance requirements.

- Q: How is steel wire rod used in the production of wire ropes for ski lifts?

- Steel wire rod plays a crucial role in the production of wire ropes used in ski lifts. This raw material is carefully chosen for its specific properties, including strength, durability, and flexibility, to ensure the wire ropes can handle the heavy loads and constant usage associated with ski lift operations. Once the appropriate steel wire rod is acquired, it goes through a series of processes to transform it into wire ropes. The wire rod is initially cleaned and then heated to a specific temperature to enhance its malleability. It is then passed through various dies to gradually reduce its diameter and shape it into a continuous length of wire. Following this, the individual wires are twisted together to form strands. The configuration of this twisting process, known as stranding, can vary depending on the desired strength and flexibility of the wire rope. The strands are subsequently compacted and laid together around a central core, resulting in the final wire rope structure. The use of steel wire rod in the production of wire ropes for ski lifts offers several advantages. Firstly, steel is renowned for its high tensile strength, enabling the wire ropes to support heavy loads and provide a safe transportation system for skiers. Additionally, the durability of steel ensures that the wire ropes can withstand harsh weather conditions and extreme temperatures on mountain slopes. Furthermore, the flexibility of steel wire rod allows the wire ropes to bend and conform to the pulleys and sheaves used in ski lift systems, ensuring smooth and reliable operation. This flexibility is crucial in preventing sudden failures or damages to the wire ropes during continuous usage. In conclusion, the utilization of steel wire rod in the production of wire ropes for ski lifts is vital for ensuring the safety, reliability, and durability of these transportation systems. The properties of steel, such as its strength and flexibility, make it an ideal material for constructing wire ropes that can withstand the demanding conditions of ski lift operations.

- Q: What are the common production processes for neptunium-coated steel wire rod?

- The common production processes for neptunium-coated steel wire rod typically include preparation of the steel wire rod, cleaning and surface treatment, application of the neptunium coating, drying or curing the coating, and final inspection and packaging.

- Q: What are the safety precautions to be taken while handling steel wire rod?

- When handling steel wire rods, it is important to take certain safety precautions to minimize risks. First and foremost, wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots is crucial to protect against potential injuries. Additionally, workers should be trained on proper lifting techniques and use mechanical aids, such as cranes or forklifts, if necessary, to avoid strain or accidents. It is important to ensure a clear and organized work area, free from any obstructions or tripping hazards. Regular inspections of the wire rods for any defects or damage should also be conducted to prevent accidents. Lastly, maintaining good communication and following established safety protocols can further enhance overall safety while handling steel wire rods.

- Q: What are the different types of steel wire rod coatings used for improved adhesion?

- There are several different types of steel wire rod coatings used for improved adhesion. These coatings are applied to the surface of the wire rod to enhance its bonding properties with other materials or substances. Some commonly used coatings include: 1. Zinc Coatings: Zinc coatings are widely used to improve adhesion in steel wire rods. The process of applying zinc to the wire rod surface is known as galvanization. Zinc coatings create a protective layer that prevents corrosion and enhances the wire rod's bonding capabilities. 2. Phosphate Coatings: Phosphate coatings are often used as a pre-treatment before applying other coatings. They create a thin layer of phosphate crystals on the wire rod's surface, which enhances adhesion and provides a good base for subsequent coatings. 3. Polymer Coatings: Polymer coatings are another popular choice for improving adhesion in steel wire rods. These coatings are typically applied as a thin layer of polymer material, such as epoxy, polyurethane, or polyester. Polymer coatings provide excellent bonding properties and also offer protection against corrosion. 4. Epoxy Coatings: Epoxy coatings are known for their exceptional adhesion properties. These coatings are applied as a two-part system, where the epoxy resin is mixed with a hardener. Epoxy coatings offer excellent resistance to chemicals, abrasion, and corrosion, making them a suitable choice for various applications. 5. Nylon Coatings: Nylon coatings are often used for wire rods that require high durability and resistance to wear and tear. These coatings offer excellent adhesion and have good mechanical properties, making them suitable for applications in industries such as automotive and construction. 6. Ceramic Coatings: Ceramic coatings provide exceptional adhesion and resistance to high temperatures. These coatings are commonly used in wire rods that are exposed to extreme heat conditions or require enhanced thermal properties. It is important to consider the specific application requirements and environmental conditions when choosing a coating for improved adhesion in steel wire rods. Each coating type has its own advantages and limitations, and selecting the right coating can significantly impact the overall performance and longevity of the wire rod.

- Q: How is steel wire rod used in the production of suspension cables?

- Steel wire rod is used in the production of suspension cables as it serves as the raw material for manufacturing these cables. The wire rod is first drawn through a series of dies to reduce its diameter and increase its strength. This process, known as wire drawing, results in a thin and strong steel wire that is then twisted or braided together to form suspension cables. These cables provide the necessary support and strength for various structures like bridges, suspension bridges, and cable-stayed bridges, ensuring their stability and load-bearing capacity.

- Q: What is the chemical composition of steel wire rod?

- The chemical composition of steel wire rod typically includes iron, carbon, manganese, silicon, and small amounts of other elements such as sulfur and phosphorus.

Send your message to us

Stainless Steel Sheet AISI 316 with Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 45555555 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords