Stainless Steel Plate AISI 316 with Best Quality in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m.t.

- Supply Capability:

- 45555555 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of stainless steel plate:

316L stainless steel containing molybdenum species, the steel containing molybdenum, the overall performance is better than steel 310 and 304 stainless steel, high temperature conditions, when the sulfuric acid concentration is less than 15% or greater than 85%, 316L stainless steel with a wide range of purposes.

Festures of stainless steel plate:

| Packaging Details: | standard packing to export 4 eye bands and 3 circumferential bands in steel, galvanized metal fluted rings on inner and outer edges |

| Delivery Detail: | 15-25 days after received your deposit or to your quantity |

Specifications of stainless steel plate:

Product Name | cr 1219x2438 stanless steel sheet 201 |

standared | JIS, AISI, ASTM, GB, DIN,SUS |

Thickness | 0.2mm~2.5mm |

Size | 1000*2000mm,1219*2438mm or as per customers' request |

Surface finish | 2B, BA, Hair Line, No.1,No.4, Mirror Finish |

Application | Kitchenware, decoration construction and building ornament |

Payment terms | T/T 30% for deposit, Balance against the copy of B/L; or L/C at sight |

Product Packing | wooden pallet |

Delivery time | within 15-20 working days after we got your 30% deposit |

Attention | FREE SAMPLES can be sent on request. |

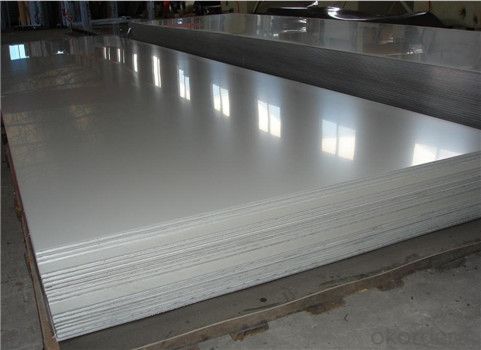

Images of stainless steel plate:

FAQ:

1. What is your package?

Packing situation: standard seaworthy packing or as customer required.

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: How is steel wire rod used in the manufacturing of wire for geotechnical applications?

- Steel wire rod is commonly used in the manufacturing of wire for geotechnical applications due to its high strength and durability. The wire rod is first drawn down to the required diameter and then further processed to enhance its mechanical properties. This processed wire is then used to create various geotechnical products, such as gabions, soil nails, and ground anchors, which are widely used in construction and civil engineering projects to provide stability, reinforcement, and erosion control.

- Q: How is the steel wire rod market affected by changes in trade policies?

- Changes in trade policies can have a significant impact on the steel wire rod market. Trade policies such as tariffs or quotas can influence the supply and demand dynamics, production costs, and competitiveness of steel wire rod producers. When trade policies impose tariffs on steel wire rod imports, it can increase the cost of importing the product, making it more expensive for domestic manufacturers to source raw materials. This can lead to an increase in the price of steel wire rod in the domestic market, affecting the profitability of manufacturers and potentially reducing the demand for the product. Conversely, if trade policies impose tariffs on steel wire rod exports, it can limit the market access for domestic manufacturers, reducing their ability to sell their products internationally and potentially impacting their revenue. Quotas on steel wire rod imports can also have a significant impact on the market. When quotas are imposed, it limits the quantity of imported steel wire rod that can enter the domestic market. This can lead to a decrease in supply, potentially creating a shortage in the market and driving up prices. On the other hand, if quotas are imposed on steel wire rod exports, it may restrict the ability of domestic manufacturers to access international markets, reducing their market reach and potentially affecting their profitability. Changes in trade policies can also impact the competitiveness of domestic steel wire rod producers. If trade policies favor domestic producers by imposing higher tariffs on imports, it can provide a competitive advantage to domestic manufacturers by making imported steel wire rod more expensive. This can incentivize domestic production and potentially lead to increased investment in the industry. Conversely, if trade policies favor imports by imposing higher tariffs on exports, it can hinder the competitiveness of domestic producers, making it difficult for them to compete in international markets. Overall, changes in trade policies can have both positive and negative impacts on the steel wire rod market. The extent of these impacts depends on the specific trade policies implemented and the reactions of market participants.

- Q: How is steel wire rod used in the manufacturing of wire forms for solar panels?

- Steel wire rod is an essential component in the manufacturing of wire forms for solar panels. It serves as the raw material that is shaped and formed into various wire structures used in the construction of solar panels. The steel wire rod undergoes a series of processes to transform it into wire forms suitable for solar panel production. The first step involves drawing the steel wire rod through a series of dies to reduce its diameter and increase its length. This process is known as wire drawing and results in a more uniform and smooth wire with the desired dimensions. Once the steel wire rod is transformed into wire, it can be further processed to create specific wire forms for solar panels. These wire forms can include support frames, interconnectors, busbars, and grounding wires. The wire forms are typically designed to provide structural stability, electrical conductivity, and mechanical support to the solar panel. The wire forms are manufactured using various techniques such as bending, cutting, welding, and shaping. The steel wire rod's malleability and strength make it an ideal material for these processes. It allows the wire to be easily shaped and formed into intricate structures while maintaining its structural integrity. Furthermore, the steel wire rod used in wire forms for solar panels is often coated or treated to enhance its durability and corrosion resistance. These protective coatings can include zinc, aluminum, or polymer-based coatings, which provide an additional layer of protection against environmental factors such as moisture and UV radiation. In summary, steel wire rod plays a crucial role in the manufacturing of wire forms for solar panels. It provides the raw material necessary to create the desired wire structures that offer structural stability, electrical conductivity, and mechanical support to the solar panel. The malleability and strength of steel wire rod allow it to be easily shaped and formed into intricate wire forms, while protective coatings enhance its durability and resistance to corrosion.

- Q: How is steel wire rod used in the manufacturing of screws and bolts?

- Steel wire rod is an essential component in the manufacturing process of screws and bolts. It serves as the raw material from which these fasteners are formed. The steel wire rod undergoes a series of manufacturing processes to transform it into screws and bolts. Firstly, the steel wire rod is heated to a high temperature to soften it. This process, known as annealing, makes the wire rod more malleable and easier to work with. Once the wire rod is heated, it is then passed through a series of dies to shape it into the desired form. These dies are specifically designed to create the thread pattern of the screw or bolt. After the wire rod has been shaped, it is cut into appropriate lengths to form individual screws or bolts. These lengths are then further processed to add the necessary features, such as the head shape and slot or recess for screwdrivers. In some cases, the wire rod may also be treated with various coatings or finishes to enhance its durability and corrosion resistance. The use of steel wire rod in the manufacturing of screws and bolts offers several advantages. Steel is known for its strength and durability, making it an ideal material for fasteners that need to withstand high levels of stress or tension. Additionally, steel wire rod is readily available and cost-effective, making it a popular choice for mass production. In conclusion, steel wire rod plays a vital role in the manufacturing of screws and bolts. It serves as the starting material, which is shaped and processed to create the final product. The use of steel wire rod ensures that screws and bolts are strong, durable, and able to fulfill their intended purpose in various applications.

- Q: How is steel wire rod used in the production of wire forms?

- Steel wire rod is used in the production of wire forms as it serves as the raw material. The wire rod is first drawn through a series of dies to reduce its diameter and increase its length. This process of drawing or cold working the wire rod helps in enhancing its strength and flexibility. The drawn wire is then further processed and shaped into various wire forms such as springs, clips, hooks, and fasteners, among others. The properties of steel wire rod, such as its high tensile strength and durability, make it an ideal material for creating strong and reliable wire forms for various industries and applications.

- Q: How is steel wire rod used in the production of wire mesh for food processing?

- Steel wire rod is an essential component in the production of wire mesh for food processing. Wire mesh, also known as wire cloth or wire fabric, is a versatile material used in various industries, including the food processing industry. It is commonly used for sieving, filtering, and separating solids and liquids during the production and processing of food products. Steel wire rod serves as the raw material for manufacturing wire mesh. It is a long, cylindrical piece of steel that is formed into coils. The wire rod is selected based on its desired properties, such as strength, durability, and corrosion resistance, which are crucial for its application in food processing. To produce wire mesh for food processing, the steel wire rod undergoes a series of manufacturing processes. The first step involves drawing the wire rod through a series of dies to reduce its diameter and achieve the desired wire thickness. This process is known as wire drawing and is done to increase the ductility and flexibility of the wire. Once the wire is drawn to the desired thickness, it is then woven or welded to form wire mesh. The weaving process involves interlacing the wires vertically and horizontally, creating a grid-like pattern. This pattern determines the size of the openings in the wire mesh, allowing for specific particle or liquid filtration. In the case of food processing, the wire mesh used is typically made of stainless steel wire rod. Stainless steel is preferred due to its high resistance to corrosion, easy cleanability, and hygienic properties. This makes it suitable for applications where food safety and cleanliness are of utmost importance. The wire mesh produced from steel wire rod is used in various ways in the food processing industry. It is commonly used as sieves or screens in food processing equipment, such as vibrating sifters or centrifugal separators, to separate or classify different-sized particles. It can also be used as a conveyor belt or conveyor screen, allowing for the transportation of food products through different stages of processing. Furthermore, wire mesh can be used as protective barriers or covers for food processing machinery, preventing contamination and ensuring worker safety. It can also be used as fencing or enclosures for storage areas or production facilities, providing a secure and controlled environment for food processing operations. Overall, steel wire rod plays a crucial role in the production of wire mesh for food processing. Its strength, durability, and corrosion resistance make it an ideal material for manufacturing wire mesh that meets the stringent requirements of the food processing industry.

- Q: How is steel wire rod used in the production of nails and screws?

- Nails and screws heavily rely on steel wire rod as a vital raw material. This exceptionally strong and durable material serves as the base for manufacturing these fasteners. To enhance its properties, the steel wire rod undergoes a series of mechanical and heat treatments. In the nail production process, the steel wire rod goes through a wire drawing machine to reduce its diameter and increase its length. This step not only improves the wire's tensile strength and smoothness but also elongates it. After being drawn, the wire is cut into specific lengths and sharpened at the ends to form nail points. Once the nails take shape, they undergo a heat treatment process called tempering. This involves subjecting them to high temperatures and then rapidly cooling them. The purpose of tempering is to increase the nails' hardness and resistance to bending or breaking, ensuring they can withstand the stress and pressure they'll encounter during use. Similarly, in screw production, the steel wire rod is drawn and cut into specific lengths. These lengths are then threaded by rolling or cutting grooves along the wire's surface, giving the screw its spiraled shape. The threading process adds strength, enabling the screw to securely fasten materials together. The steel wire rod used for nails and screws is usually made from low-carbon, high-carbon, or alloy steel. Each type of steel offers specific properties, such as corrosion resistance or increased strength, depending on the intended application of the fasteners. All in all, steel wire rod plays a vital role in the production of nails and screws. Its strength, durability, and versatility make it an ideal material for these fasteners, ensuring they can effectively hold materials together in various construction, manufacturing, and household applications.

- Q: How is the corrosion resistance of steel wire rod improved?

- There are several methods and techniques available to enhance the corrosion resistance of steel wire rods. One effective approach is to apply protective coatings. Coatings made of zinc, aluminum, or other corrosion-resistant metals can be used to create a barrier between the steel and corrosive elements in the surrounding environment. These coatings act as sacrificial layers, corroding instead of the steel and extending the lifespan of the wire rods. Another way to improve corrosion resistance is through galvanization. This involves immersing the steel wire rod in molten zinc, which forms a protective layer on its surface. The galvanized coating acts as both a physical barrier against corrosion and a source of cathodic protection for the steel, minimizing the risk of corrosion. Corrosion resistance can also be enhanced by alloying the steel with specific elements. For example, stainless steel wire rods are widely used in applications where corrosion resistance is critical. Stainless steel contains a high percentage of chromium, which forms a self-repairing oxide layer on the surface, protecting the steel from corrosion. Additionally, the surface finish of the steel wire rod can influence its resistance to corrosion. Smoother and more polished surfaces tend to offer better protection against corrosion compared to rougher surfaces, as they have fewer crevices and imperfections for corrosive agents to penetrate. Proper maintenance and storage practices are also crucial for preserving the corrosion resistance of steel wire rods. This includes keeping them in dry environments, shielding them from moisture or corrosive substances, and promptly addressing any signs of corrosion, such as rust, by cleaning and applying suitable corrosion inhibitors. To summarize, enhancing the corrosion resistance of steel wire rods involves a combination of coating techniques, alloying, surface finishing, and proper maintenance. These measures ensure the longevity and performance of the wire rods in corrosive environments.

- Q: What is the average lifespan of steel wire rod?

- The average lifespan of steel wire rod can vary depending on various factors such as the quality of the steel, the environment it is exposed to, and the level of maintenance it receives. Generally, steel wire rod is designed to be durable and long-lasting. With proper care and maintenance, it can last for many years. However, if the steel wire rod is exposed to harsh conditions such as extreme temperatures, corrosive substances, or excessive stress, its lifespan may be shortened. It is also important to note that the average lifespan of steel wire rod can vary depending on its specific application. For example, steel wire rod used in construction may have a different lifespan compared to steel wire rod used in electrical wiring. Therefore, it is advisable to consult the manufacturer or industry standards for a more accurate estimate of the average lifespan of steel wire rod in a specific application.

- Q: How is steel wire rod used in the production of wire for suspension bridge cables?

- The production of wire for suspension bridge cables heavily relies on steel wire rod, a crucial component. This wire rod is made from high-quality steel and is typically manufactured through the process of hot rolling. To create the wire for suspension bridge cables, the steel wire rod goes through various stages of processing. Initially, the wire rod is heated and then passed through a series of rollers, gradually reducing its size and shaping it into a continuous, long wire. This process is commonly referred to as wire drawing. The resulting wire then undergoes further processing to enhance its strength and durability. It is subjected to a heat treatment process, like annealing, which improves its mechanical properties. This treatment increases the wire's tensile strength, ensuring it can endure the immense loads and stresses experienced by suspension bridge cables. Once the wire has been appropriately treated, it is meticulously woven and braided to form the final suspension bridge cable. Multiple wires are twisted together to create strands, and several strands are then twisted together to form a larger cable. This intricate weaving process guarantees that the cable is strong, flexible, and corrosion-resistant. The use of steel wire rod in the production of suspension bridge cables is crucial because of its exceptional strength-to-weight ratio. Steel is renowned for its high tensile strength, making it ideal for supporting heavy loads over long distances. Moreover, steel wire rod offers excellent resistance to corrosion, ensuring the durability and structural integrity of suspension bridge cables. In conclusion, steel wire rod plays a vital role in producing wire for suspension bridge cables, providing the necessary strength, durability, and flexibility required for these critical infrastructure components. Its versatility and reliability make it the preferred material choice in constructing suspension bridge cables, guaranteeing the safety and functionality of these remarkable engineering marvels.

Send your message to us

Stainless Steel Plate AISI 316 with Best Quality in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 m.t.

- Supply Capability:

- 45555555 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords