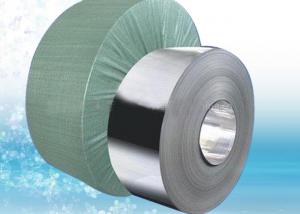

201 2B Stainless Steel Strips

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

201 2B Stainless Steel Strips

1. Chemical composition of 201 2B Stainless Steel Strips

C | Si | Mn | P | S | Ni | Cr |

max0.15 | max1.00 | 5.50-7.50 | max0.06 | max0.03 | max1.00 | 16.00-18.00 |

2. Mechanical properties of 201 2B Stainless Steel Strips

Yield Strength | Tensile | Elongation | Hardness (HV) | Hardness (HRB) |

245 | 640 | 40 | 253 | 100 |

3. Standard:

AISI, ASTM, GB, EN, DIN, JIS

4. Surface:

2B, NO.1, BA, NO.4, Hairline, SB, Mirror finish, Anti-skid, Cherkered etc.

5. Size:

Thickness: 0.3-3mm (cold rolled), 3-40mm (hot rolled)

Width: 1000mm or 1219mm or 1240mm for cold rolled, 1500mm for hot rolled.

Length: As customers' request.

6. MOQ: 1 Ton

7. Payment terms:T/T or L/C

8. Packing:

Seaworthy package with wooden or Iron pallets with the paper and the steel strip, or as customers' request.

9. Delivery time:

Usually about 7 days after we confirming the order, or according to your quantity.

If you have any question or demand, pls feel free to contact me.

- Q: Can stainless steel wire be used for cable railing systems?

- Yes, stainless steel wire can be used for cable railing systems. Stainless steel is a durable and corrosion-resistant material, making it a popular choice for cable railings. It provides strength and stability while also offering an aesthetically pleasing appearance.

- Q: Can stainless steel wire be used for aircraft components?

- Yes, stainless steel wire can be used for aircraft components. Stainless steel is known for its high strength, corrosion resistance, and ability to withstand extreme temperatures, which makes it a suitable material for various aircraft applications. Stainless steel wire can be used in the construction of structural components, such as cables, ropes, and springs, as well as in electrical and mechanical systems. It is often used in critical areas where reliability and durability are paramount, such as in landing gear, control systems, and engine components. Additionally, stainless steel wire is lightweight compared to other metals, which is crucial in aircraft design to minimize weight and maximize fuel efficiency. Overall, stainless steel wire is a versatile and reliable material for aircraft components.

- Q: What are the different types of stainless steel wire brushes?

- A variety of stainless steel wire brushes are available, each designed for specific purposes and applications. The most common types are as follows: 1. Crimped wire brushes: These brushes feature a crimped wire pattern, which enhances flexibility and surface coverage. They are commonly used for light to medium-duty cleaning and deburring tasks. 2. Knotted wire brushes: With twisted wire knots, these brushes provide a more aggressive brushing action. They are perfect for heavy-duty tasks like removing rust, weld scale, and corrosion from metal surfaces. 3. Cup brushes: These brushes have a cylindrical shape with bristles arranged in a cup-like configuration. They are typically employed in cleaning large flat surfaces, such as eliminating paint or rust from metal parts. 4. Wheel brushes: Similar to cup brushes, wheel brushes have a wheel-shaped design. They are often utilized for cleaning and finishing applications on curved or irregular surfaces. 5. End brushes: End brushes have bristles arranged in a circular pattern at the brush's end. They are commonly employed for reaching tight or hard-to-reach areas, such as cleaning threads, grooves, or crevices. 6. Miniature brushes: These small brushes are frequently used for precision cleaning or detailing work. Industries like jewelry making, electronics, or dental applications commonly employ them. 7. Strip brushes: Strip brushes consist of a strip of stainless steel wire bristles held together by a metal or plastic backing. They are frequently used in industrial applications like sealing gaps, dust or debris removal, or conveyor belt cleaning. Each type of stainless steel wire brush possesses unique characteristics and applications, making it essential to select the appropriate brush for the specific task at hand.

- Q: What are the different types of stainless steel wire surface finishes?

- Different types of surface finishes are available for stainless steel wire, each with its own unique characteristics and advantages. Some of the most commonly used finishes are as follows: 1. Achieving a highly reflective and smooth surface, the Bright Annealed (BA) Finish involves annealing the stainless steel wire in a controlled atmosphere. It is frequently utilized for decorative purposes, where a shiny and visually appealing look is desired. 2. Known as a hot-rolled annealed and pickled (HRAP) finish, the No. 1 Finish is obtained through hot rolling, followed by annealing and pickling. It exhibits a dull and rough appearance, often preferred for industrial applications where aesthetics are not a primary concern. 3. For a smooth and even appearance, the No. 2B Finish is attained by cold rolling the wire, followed by annealing and descaling. It displays a moderately reflective surface and finds common usage in applications such as kitchen appliances and architectural components. 4. The No. 4 Finish is achieved by progressively polishing the wire with finer abrasives until a uniform and smooth surface is obtained. It presents a brushed appearance and is commonly employed in applications where both aesthetics and functionality hold importance, such as elevator doors and decorative elements. 5. Referred to as a mirror or reflective finish, the No. 8 Mirror Finish involves further polishing the wire to achieve a highly reflective and mirror-like surface. It is often utilized in decorative applications, where a high-end and luxurious appearance is desired. 6. The Electro-Polished (EP) Finish entails subjecting the wire to an electrochemical process that eliminates surface imperfections and enhances corrosion resistance. This process produces a smooth and bright surface finish, making it a popular choice in industries where hygiene and cleanliness are critical, such as pharmaceutical and food processing. It should be noted that the choice of the appropriate surface finish depends on several factors, including the intended application, desired appearance, and specific requirements of the wire.

- Q: 304 what's the difference between stainless steel and 316?

- 316 contains Mo, 304 does not contain. The function of Mo is to prevent embrittlement of steel by the agent of carbonation.316 and 304 chromium, like nickel, higher than 304, better corrosion resistance. General 316 for the Navy steel, used in the sea more.

- Q: Stainless steel drawing plate, polishing plate, mirror panels of the three differences

- Stainless steel polishing plate refers to: stainless steel polishing plate refers to the polished stainless steel polished plate through the polishing machine, this kind of polishing board generally brightness is not high, but also can shine out of fuzzy figure.

- Q: Can stainless steel wire be used for heating elements?

- Yes, stainless steel wire can be used for heating elements. Stainless steel is a popular choice for heating elements due to its high resistance to heat and corrosion. It has excellent electrical conductivity and can withstand high temperatures without deforming or deteriorating. Stainless steel wire can be easily formed into different shapes and sizes to suit the specific heating requirements of various applications. However, it's important to note that the specific grade and composition of stainless steel should be carefully selected to ensure optimal performance and longevity of the heating element.

- Q: What are the different types of finishes available for stainless steel wire?

- There are several types of finishes available for stainless steel wire, each offering unique characteristics and benefits. 1. Bright Annealed Finish: This is a smooth, reflective finish achieved by annealing the wire in a controlled atmosphere. It provides excellent corrosion resistance and is commonly used in applications where aesthetics are important, such as architectural and decorative applications. 2. Mill Finish: Also known as a raw or unfinished finish, this is the standard finish produced by the initial manufacturing process. It has a dull appearance and is typically used for applications where aesthetics are not a primary concern. 3. Brushed Finish: This finish is achieved by brushing the wire with an abrasive material, resulting in a textured, satin-like appearance. It provides good corrosion resistance and is often used in applications where a more visually appealing finish is desired, such as kitchen appliances and automotive trim. 4. Electro-Polished Finish: This is a high-gloss finish achieved through an electrochemical process that removes a thin layer of surface material. It provides excellent corrosion resistance, smoothness, and cleanliness, making it suitable for applications that require high hygiene standards, such as pharmaceutical and food processing equipment. 5. Passivated Finish: This finish involves treating the wire with a chemical solution to remove surface contaminants and enhance its corrosion resistance. It is commonly used in applications where the wire will be exposed to harsh environments or corrosive substances, such as marine and chemical processing industries. 6. Coated Finish: Stainless steel wire can also be coated with various materials to enhance its performance and appearance. Common coating options include nylon, PVC, and polyethylene. These coatings provide added protection against corrosion, abrasion, and electrical insulation, making them suitable for applications like fencing, electrical wiring, and cable assemblies. In summary, the different types of finishes available for stainless steel wire include bright annealed, mill finish, brushed, electro-polished, passivated, and coated finishes. The choice of finish depends on the specific requirements of the application, such as corrosion resistance, aesthetics, hygiene standards, and environmental conditions.

- Q: What are the different types of stainless steel wire rope clips?

- Various types of stainless steel wire rope clips are available on the market, including standard wire rope clips, u-bolt wire rope clips, and saddle wire rope clips. 1. Standard wire rope clips are the most commonly utilized type. They comprise a saddle, a u-bolt, and two nuts. The wire rope is placed under the saddle, the u-bolt is threaded through the saddle's holes and around the wire rope, and the nuts are tightened to secure the wire rope firmly. 2. U-bolt wire rope clips, on the other hand, feature a u-shaped bolt that is threaded through the saddle's holes and around the wire rope. They are particularly suitable for applications that require a higher load capacity as they provide a more secure grip. 3. Saddle wire rope clips solely consist of a saddle and two nuts, without a u-bolt. The nuts are directly threaded onto the saddle's threaded ends. These clips are commonly used when the wire rope needs to be tightly secured and when the load capacity is not as high as that of u-bolt wire rope clips. It is worth noting that the stainless steel type used in the construction of these wire rope clips can also vary. 304 and 316 stainless steel are commonly utilized, with 316 stainless steel being more resistant to corrosion and suitable for marine environments or applications involving harsh chemicals.

- Q: What are the different types of stainless steel wire used for cable railing?

- There are several different types of stainless steel wire commonly used for cable railing systems. These types include: 1. 304 Stainless Steel Wire: This is the most commonly used type of stainless steel wire for cable railing. It is durable, corrosion-resistant, and offers good strength. It is suitable for most indoor and outdoor applications. 2. 316 Stainless Steel Wire: This type of stainless steel wire is considered marine-grade and offers superior corrosion resistance compared to 304 stainless steel. It is highly recommended for cable railing systems installed in coastal or high-humidity environments. 3. 316L Stainless Steel Wire: Similar to 316 stainless steel, 316L stainless steel wire is also marine-grade and has even better corrosion resistance. It contains lower levels of carbon, making it more suitable for welding applications. 4. 7x7 Stainless Steel Wire: This type of stainless steel wire is made up of seven strands, each consisting of seven individual wires. It offers good flexibility and is commonly used for cable railing systems that require some degree of flexibility. 5. 1x19 Stainless Steel Wire: This type of stainless steel wire is made up of one strand consisting of 19 individual wires. It is stiffer and more rigid compared to 7x7 wire, making it suitable for straight runs or applications where minimal flexibility is required. 6. 7x19 Stainless Steel Wire: This type of stainless steel wire is made up of seven strands, each consisting of 19 individual wires. It offers good flexibility and strength, making it suitable for cable railing systems that require both. When choosing the type of stainless steel wire for cable railing, it is important to consider factors such as the environment, load requirements, and aesthetic preferences. Consulting with a professional or supplier can help in selecting the most appropriate stainless steel wire for your specific cable railing project.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 2005 |

| Annual Output Value | Above US$1.6 million |

| Main Markets | Europe, North America. |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 40% |

| No.of Employees in Trade Department | Above 30 people |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | Above 5000 square meter |

| No. of Production Lines | Above 6 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

201 2B Stainless Steel Strips

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Ton m.t.

- Supply Capability:

- 2000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords