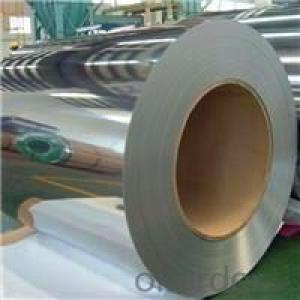

Cold Rolled Steel Strip Stainless Steel Strip Coils

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | cold rolled stainless steel strip coils is packed in export standard package |

| Delivery Detail: | cold rolled stainless steel strip coils finished within 15 days |

Specifications

1,cold rolled stainless steel strip coils thickness0.2~1.5mm

2.Ensure you quality timely deliver

3.2B finish

4.Tolerance 0.01

Item Details:

1, cold rolled stainless steel strip coils with thickness 0.2~1.5mm

2, Finishing: 2B

3, Width: 15~500mm

4. Tolerance: -0.01mm~0.01mm

Our advantage

1, High quality: Using lastest automated control equipment to ensure china stainless steel coil quality, such as AGC system.

2, Best Price: With most automated equipments to cost down.

3, Fast delivery: Since your order placed, ETD will be only 10 days.

4, Best Sevice: We do believe your encouragement is the best support for us.

Shipping information:

1, Payment terms: T/T 30% for depsoit, Balance against the copy of B/L; or L/C at sight

2, ETD: 10-15 days after the receipt of the deposit

3, Ship terms: FOB Ningbo

4, Minimum quantity: 5 tons

Contact and Feedback:

If you are interested in any of cold rolled stainless steel strip coils or any question, please feel free to contact us. We will reply you within 24H.

- Q: What are the different methods for removing coatings from steel strips?

- There are several methods for removing coatings from steel strips, including mechanical methods such as sanding, scraping, or wire brushing, chemical methods involving the use of solvents or acids, thermal methods like burning or melting, and abrasive methods like blasting with abrasive materials such as sand or grit. The choice of method depends on the type and thickness of the coating, as well as the desired outcome and specific requirements of the project.

- Q: What are the different grades of steel used in steel strips?

- There are several different grades of steel commonly used in steel strips, each with its own unique properties and applications. Some of the most commonly used grades include: 1. Low carbon steel: This grade of steel has a carbon content ranging from 0.05% to 0.25%. It is known for its excellent formability, weldability, and versatility. Low carbon steel is often used in applications where strength and hardness are not critical, such as automotive components, construction materials, and consumer goods. 2. Medium carbon steel: With a carbon content ranging from 0.25% to 0.60%, medium carbon steel offers a balance between strength and ductility. It is commonly used in applications that require moderate strength and hardness, such as shafts, gears, and machinery parts. 3. High carbon steel: This grade of steel contains a carbon content ranging from 0.60% to 1.0%, providing excellent strength and hardness. High carbon steel is commonly used in applications where extreme hardness and wear resistance are required, such as cutting tools, springs, and knives. 4. Stainless steel: Stainless steel is an alloy that contains a minimum of 10.5% chromium, which provides excellent corrosion resistance. It is available in various grades, each with different levels of corrosion resistance, formability, and strength. Stainless steel strips are widely used in industries such as food processing, medical equipment, and automotive applications. 5. Galvanized steel: Galvanized steel is coated with a layer of zinc to provide enhanced corrosion resistance. It is commonly used in applications where rust prevention is crucial, such as outdoor structures, automotive parts, and electrical enclosures. 6. Alloy steel: Alloy steel is composed of multiple alloying elements, such as chromium, nickel, or molybdenum, in addition to iron and carbon. These additional elements enhance the mechanical properties of the steel, such as strength, hardness, and toughness. Alloy steel strips are often used in applications that require high-performance materials, such as aircraft parts, automotive components, and industrial machinery. Overall, the choice of grade depends on the specific requirements of the application, considering factors such as strength, hardness, corrosion resistance, and cost. Different grades of steel offer a wide range of properties, allowing for the selection of the most suitable grade for each specific application.

- Q: How are steel strips shaped into various forms?

- Steel strips are shaped into various forms through a process called metal forming, which involves techniques such as rolling, bending, stretching, and stamping. These methods utilize specialized machinery and tools to manipulate the steel strips, applying force and pressure to achieve desired shapes and dimensions.

- Q: How are steel strips used in the production of aircraft structures?

- Steel strips are commonly used in the production of aircraft structures for various purposes such as reinforcing, joining, and providing structural integrity. They are typically used to strengthen and support critical components, such as wings, fuselage, and landing gear, by being formed into specific shapes or profiles. Steel strips also serve as connectors, helping to secure different parts of the aircraft together, enhancing stability and durability. Furthermore, they can be used as a protective layer or coating to prevent corrosion and increase the overall lifespan of the aircraft.

- Q: What are the factors that affect the electrical conductivity of steel strips?

- There are several factors that can affect the electrical conductivity of steel strips. 1. Composition: The composition of the steel strip plays a significant role in its electrical conductivity. Steel is primarily composed of iron, but it also contains other elements such as carbon, manganese, silicon, and various alloying elements. These elements can affect the electrical conductivity of the steel strip. For example, high carbon content can decrease electrical conductivity, while certain alloying elements like copper or nickel can increase conductivity. 2. Impurities: The presence of impurities in the steel strip can also impact its electrical conductivity. Impurities such as sulfur, phosphorus, and oxygen can introduce resistance to the flow of electrical current, thereby reducing conductivity. The level of impurities in the steel, therefore, needs to be minimized during the manufacturing process. 3. Grain size: The grain size of the steel strip can influence its electrical conductivity. Generally, smaller grain sizes have higher electrical conductivity due to the increased number of grain boundaries, which facilitate the movement of electrons. Heat treatment processes can be employed to control and optimize the grain size of the steel strip. 4. Temperature: Electrical conductivity of steel strips can be affected by temperature. As the temperature increases, the electrical resistance of the steel also increases, leading to a decrease in conductivity. This phenomenon is known as the temperature coefficient of resistance. It is important to consider the operating temperature range when selecting a steel strip for electrical applications. 5. Surface conditions: The surface condition of the steel strip can impact its electrical conductivity. Factors such as surface roughness, oxide layers, and contamination can introduce resistance, thereby reducing conductivity. Proper cleaning and surface treatment methods can be employed to improve the electrical conductivity of steel strips. 6. Thickness and cross-sectional area: The thickness and cross-sectional area of the steel strip can influence its electrical conductivity. Thicker strips generally have lower conductivity due to the increased path length for electron flow. Similarly, larger cross-sectional areas allow for more efficient electron movement, resulting in higher conductivity. It is crucial to consider these factors when designing and selecting steel strips for electrical applications, as they can greatly impact the overall performance and efficiency of electrical systems.

- Q: Can steel strips be used in the production of watch straps?

- Watch straps can indeed be made using steel strips. The reason behind the popularity of steel strips as a material for watch straps lies in their durability, strength, and resistance to corrosion. These strips can be molded and adjusted to suit various watch designs and wrist sizes. Moreover, steel strips can be polished or coated with different finishes to elevate their look and make them visually attractive. All in all, steel strips offer a dependable and fashionable alternative for watch straps.

- Q: Are steel strips suitable for machining or drilling operations?

- Yes, steel strips are suitable for machining or drilling operations. Steel strips are typically made from high-strength steel alloys, which make them ideal for various manufacturing processes including machining and drilling. These strips can be easily shaped, cut, or drilled to meet specific design requirements. Additionally, steel strips offer excellent durability and resistance to wear, making them suitable for heavy-duty machining or drilling applications.

- Q: What are the standard lengths of steel strips?

- The standard lengths of steel strips can vary depending on the specific industry and application. However, in general, steel strips are commonly available in standard lengths of 20 feet or 6 meters. These lengths are suitable for various uses, such as manufacturing, construction, and fabrication. Additionally, custom lengths can also be obtained by cutting the steel strips to the desired size using appropriate tools and equipment. It is advisable to consult the supplier or manufacturer for specific length requirements based on the intended use.

- Q: How are steel strips tested for quality?

- Steel strips are tested for quality through a series of rigorous quality control processes. These tests are conducted to ensure that the steel strips meet the required specifications and comply with industry standards. One of the primary tests performed is the visual inspection, where the strips are examined for any surface defects, such as cracks, scratches, or dents. This inspection is crucial in identifying any issues that may affect the structural integrity or appearance of the steel strips. Another important quality test is the dimensional inspection, which involves measuring the width, thickness, and length of the steel strips. This ensures that the strips are manufactured to the precise dimensions required for their intended application. Any deviations from the specified dimensions can result in the strips being rejected. Mechanical properties of the steel strips are evaluated through various tests such as tensile strength, yield strength, and elongation. These tests determine the strength, ductility, and elasticity of the steel strips, which are essential factors in determining their overall quality. Surface quality is also assessed through tests such as hardness testing and surface roughness measurement. Hardness testing checks the resistance of the steel strip to indentation or penetration, while surface roughness measurement evaluates the smoothness or roughness of the strip's surface. Additionally, chemical composition analysis is conducted to verify the composition of the steel strips, ensuring that they contain the correct elements in the required proportions. This analysis is crucial in determining the steel's corrosion resistance, strength, and other mechanical properties. Furthermore, steel strips may undergo tests such as corrosion resistance evaluation, impact testing, and bend testing to assess their durability and performance under different conditions. Overall, the quality testing of steel strips involves a combination of visual inspections, dimensional checks, mechanical property evaluations, surface quality assessments, and chemical composition analysis. These tests are essential in ensuring that the steel strips meet the required standards and perform optimally in their intended applications.

- Q: Can steel strips be cut to custom sizes?

- Yes, steel strips can be cut to custom sizes. Steel strips are commonly used in various industries and applications, and they are available in different widths, thicknesses, and lengths. Depending on the specific requirements of a project or application, steel strips can be easily cut to custom sizes. This can be done using various cutting methods such as shearing, sawing, or laser cutting. These cutting methods allow for precise and accurate customization of steel strips to meet the desired specifications.

Send your message to us

Cold Rolled Steel Strip Stainless Steel Strip Coils

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords