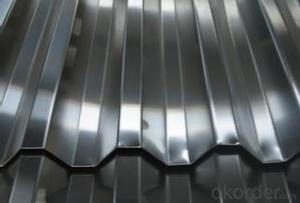

Stainless Steel Coil with Good Price China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

| Product name | stainless steel coil |

| Grade | (200 series& 300 series& 400 series..etc) 1.4301, 1.4306, 1.4845, 1.4401, 1.4371, 1.4597,1.4541, etc |

Standard | GB, JIS, ASTM, AISI |

Surface | pickled,bright or black |

Wall Thickness | range from0.3-38.1mm |

Outer Diameter | 0.5mm-530mm |

Length | AS PER CUSTOMER |

| Usage | Widely used in the areas such as fluid and gas transport,decoration,construction,medical equipment,aviation,boiler heat-exchanger and other fields. |

| Condition of delivery | Austenite in solution,ferrite in anneal or in accordance with client's detailed requirement |

| MOQ | 1 Metric ton |

| Price terms | CIF or FOB Shanghai |

| Payment terms | L/C or T/T |

| supply ability | 25 Metric tons per day |

| Delivery Detail | 7-30 days,according to the quantity. |

| Packaging Detail | Standard seaworthy package(1.plywood case2.wooden pallet package 3.bundle package and other package or as customer request)

|

Packaging & Shipping

Packaging

shipping

Our Services

Trade details (kindly need your attention)

1) Above all, in your inquiry, besides the diameter, please indicate clearly: the material of your required wire;

your requirement of surface and soft wire or hard wire . Because those are aslo key to calculating our cost and telling you prices for your ordered wire

2) Packing: standard export packing.

3) Payment:by L/C sight or T.T against copy of B/L

4) Shipment:10~15 days after receipt of the down payment or Irrevocable L/C sight.

5) Trade terms:FOB SHANGHAI,or CIF discharging port.

Our Advantages

(1): High quality stainless steel tube with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements. Free sample

- Q: What is the minimum order quantity for stainless steel strips?

- The minimum order quantity for stainless steel strips may vary depending on the supplier or manufacturer. It is advisable to check with the specific supplier or manufacturer to determine their minimum order quantity requirements.

- Q: Are 111 stainless steel strips suitable for the food and beverage industry?

- Yes, 111 stainless steel strips are suitable for the food and beverage industry.

- Q: Are stainless steel strips suitable for HVAC applications?

- Yes, stainless steel strips are suitable for HVAC (heating, ventilation, and air conditioning) applications. Stainless steel is a highly versatile and durable material that offers excellent resistance to corrosion, heat, and pressure. These characteristics make it ideal for use in HVAC systems, which often operate in demanding environments. Stainless steel strips are commonly used in HVAC applications for various purposes. They are frequently used for manufacturing air ducts, which are essential components in HVAC systems for distributing heated or cooled air throughout a building. Stainless steel strips provide the necessary strength, rigidity, and resistance to withstand the pressure and temperature fluctuations that occur in ductwork. Additionally, stainless steel strips are also used in HVAC systems for producing heat exchangers, which are crucial for transferring thermal energy between fluids. The corrosion resistance of stainless steel ensures that the heat exchangers can withstand the exposure to different liquids and gases without deteriorating over time. Furthermore, stainless steel strips are preferred in HVAC applications due to their hygienic properties. They are easy to clean, maintain, and do not support the growth of bacteria or mold, making them ideal for use in environments where air quality is critical, such as hospitals and laboratories. In conclusion, stainless steel strips are well-suited for HVAC applications. Their excellent corrosion resistance, durability, and hygienic properties make them a reliable choice for manufacturing air ducts, heat exchangers, and other components used in HVAC systems.

- Q: How do stainless steel strips perform in the presence of hydrochloric acid?

- Stainless steel strips generally perform well in the presence of hydrochloric acid due to their high corrosion resistance properties. Hydrochloric acid is a highly corrosive substance that can deteriorate many metals, but stainless steel has a unique composition that makes it resistant to this type of chemical attack. The presence of chromium in stainless steel forms a protective oxide layer on the surface, which prevents the acid from reaching the underlying metal and causing corrosion. Additionally, stainless steel contains nickel, which further enhances its resistance to acids. However, it is important to note that the performance of stainless steel in hydrochloric acid can vary depending on the grade and specific conditions of exposure. Higher grades of stainless steel, such as 316 or 904L, are often preferred for more aggressive acid environments. It is recommended to consult with material experts or refer to corrosion resistance charts to select the appropriate stainless steel grade for specific hydrochloric acid applications.

- Q: What are the surface finishes available for 111 stainless steel strips?

- There are several surface finishes available for 111 stainless steel strips. Some common finishes include: 1. No. 1 Finish: This is a hot-rolled, annealed, and pickled finish that is characterized by a rough, dull appearance. It is commonly used for industrial applications where appearance is not a priority. 2. No. 2B Finish: This is a bright, cold-rolled finish that is commonly used for applications that require a smooth and reflective surface. It is often used in decorative and architectural applications. 3. No. 2D Finish: This is a dull, cold-rolled finish that is similar to the No. 2B finish but has a slightly rougher surface. It is often used for applications that require a smooth surface but do not require a high level of reflectivity. 4. No. 3 Finish: This is a semi-polished finish that is obtained by using abrasives with a finer grit compared to the No. 2D finish. It provides a smoother and more uniform surface, making it suitable for applications that require a visually appealing finish. 5. No. 4 Finish: This is a brushed finish that is achieved by using abrasive belts or brushes to create a consistent pattern of fine lines on the surface. It is commonly used for decorative purposes, such as in architectural and kitchen applications. 6. No. 8 Mirror Finish: This is a highly reflective finish that is achieved by polishing the surface to a mirror-like appearance. It is often used in applications that require a high level of reflectivity, such as in mirrors or decorative items. These are just a few of the surface finishes available for 111 stainless steel strips. The choice of finish depends on the specific requirements of the application, including aesthetics, corrosion resistance, and functionality.

- Q: Can stainless steel strips be polished?

- Yes, stainless steel strips can be polished. Polishing stainless steel strips helps to improve their appearance by creating a smooth and shiny surface.

- Q: What are the different types of edges for stainless steel strips?

- Various types of edges can be used in the manufacturing of stainless steel strips, each fulfilling a specific purpose and application. Some commonly used types of edges for stainless steel strips include: 1. Mill Edge: This edge, which is produced during the manufacturing process, is the most common type. It has a slightly rounded or curved shape, making it suitable for general applications. 2. Slit Edge: By slitting the stainless steel strip into narrower widths, this type of edge is achieved. It is typically a straight edge, although it may have slight burrs or roughness. Industries that don't require precision and tight tolerances often use slit edges. 3. Deburred Edge: To eliminate any burrs or roughness on the slit edge, a deburring process is applied. This results in a smooth and rounded edge, ensuring safety and preventing damage during handling. 4. Rolled Edge: Rolling the stainless steel strip produces this type of edge, which is smooth and rounded. Rolled edges are commonly used in applications where safety and aesthetics are important, such as in architectural and decorative uses. 5. Beveled Edge: A beveled edge refers to an angled or sloping cut made on the edge of the stainless steel strip. It is typically used in applications that require welding or joining, as the bevel facilitates better weld penetration and joint strength. 6. Sheared Edge: This type of edge is achieved by cutting the stainless steel strip with a sharp blade. Sheared edges may have slight variations and irregularities but are suitable for applications where precision is not critical. 7. Custom Edges: Depending on specific requirements, stainless steel strips can be manufactured with custom edges. These edges are tailored to meet the unique needs of the application, such as special chamfers, grooves, or profiles. When selecting the appropriate type of edge, it is crucial to consider the intended use and requirements of the stainless steel strip. The choice of edge can impact the functionality, appearance, and compatibility of the strip with different manufacturing processes.

- Q: Does the 301 stainless steel band contain magnetism?

- 301 is our country's 1Cr17Ni7, belongs to 18-8 type austenitic stainless steel varieties, itself should be no magnetism, there is opportunity processing and pressure processing may produce processing magnetism, but after the heat treatment, magnetism will disappear

- Q: Can stainless steel strips be used for electrical conductivity?

- Yes, stainless steel strips can be used for electrical conductivity. While stainless steel is not as conductive as other metals like copper or aluminum, it still possesses a certain level of conductivity that allows it to be used in various electrical applications.

- Q: Are stainless steel strips suitable for decorative railing systems?

- Indeed, decorative railing systems can be complemented with stainless steel strips. Stainless steel possesses remarkable traits such as durability, resistance against corrosion, and aesthetic charm, rendering it a superb option for embellishing purposes. By skillfully shaping and sizing stainless steel strips, intricate and fashionable railing designs can be effortlessly achieved. Moreover, stainless steel requires minimal upkeep and can endure harsh weather conditions, thus making it the perfect choice for outdoor decorative railing systems.

Send your message to us

Stainless Steel Coil with Good Price China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords