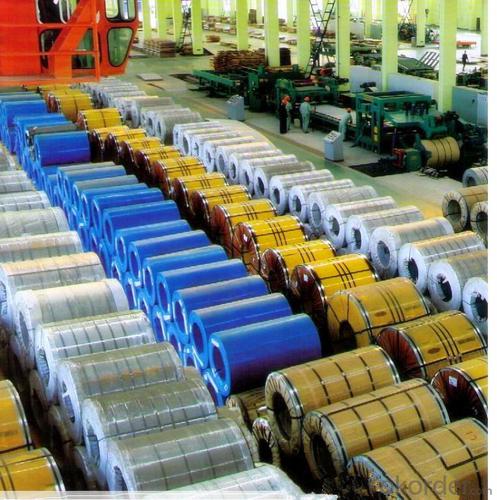

Stainless Steel Coil 304 Hot Rolled Surface No.1

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled Stainless Steel Coil 304 Annealing and Pickling No.1 Finish

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely

used in light industry,heavy industry,daily necessities and the decoration industry.

Hot Rolled Stainless Steel Coil 304 Specifications

1.surface:NO.1

2.standard:JIS, AISI, GB

3.width: 0.55m, 0.65m, 1.0m, 1.22m, 1.5m, 2m or requirement

Hot Rolled Stainless Steel Coil 304 Chemical Composition:

(%):C=0.07, Mn=2.00, P=0.045, S=0.030, Si=0.075, Cr=17.5-19.5, Ni=8.0-10.5, N=0.10

Hot Rolled Stainless Steel Coil 304 Physical Properties

Tensile strength σb (MPa) ≥ 520

the conditions yield strength σ0.2 (MPa) ≥ 205,

elongation δ5 (%) ≥ 40

Reduction of ψ (%) ≥ 50,

hardness: ≤ 187

HB; ≤ 90

HRB; ≤ 200H

- Q: Are stainless steel strips resistant to UV radiation?

- Yes, stainless steel strips are generally resistant to UV radiation. Stainless steel is known for its excellent corrosion resistance, and this includes resistance to the damaging effects of UV radiation. The chromium content in stainless steel forms a protective oxide layer on its surface, which helps to prevent UV radiation from causing any significant damage or degradation to the material. Additionally, stainless steel is often used in outdoor applications and environments where it is exposed to sunlight and UV radiation, such as architectural structures, automotive parts, and marine equipment, further indicating its resistance to UV radiation. However, it is important to note that the specific resistance of stainless steel strips to UV radiation may vary depending on the grade and quality of the stainless steel used, as well as the duration and intensity of the UV exposure.

- Q: Can stainless steel strips be used in the production of kitchen sinks?

- Kitchen sinks can indeed incorporate stainless steel strips. The durability, resistance to corrosion, and ability to uphold a clean and hygienic surface are reasons why stainless steel is a favored material for kitchen sinks. Shaping and welding stainless steel strips allows for the creation of diverse sink components, including the basin and drainboard. Moreover, polishing the strips grants a polished and sleek appearance. Notably, stainless steel strips provide effortless maintenance and ensure enduring performance, rendering them an ideal selection for producing kitchen sinks.

- Q: How do you prevent rust on stainless steel strips?

- To prevent rust on stainless steel strips, there are several measures you can take: 1. Regular cleaning and maintenance: It is important to clean stainless steel strips regularly to remove any dirt, debris, or contaminants that could lead to rust formation. Use a mild detergent or stainless steel cleaner and a soft cloth or sponge to clean the surface thoroughly. Avoid using abrasive cleaners or scrub brushes, as they can scratch the stainless steel and make it more prone to rusting. 2. Dry thoroughly: After cleaning, make sure to dry the stainless steel strips completely. Moisture can contribute to rust formation, so using a clean, dry cloth to wipe away any residual moisture is crucial. Pay special attention to areas where water can accumulate, such as crevices or corners. 3. Protect from chemicals and corrosive substances: Stainless steel is known for its resistance to corrosion, but certain chemicals or substances can still cause damage or rusting. Avoid exposing stainless steel strips to harsh chemicals, such as bleach or ammonia-based cleaners, as they can corrode the surface. If stainless steel comes into contact with corrosive substances, rinse it immediately with water and dry thoroughly. 4. Use protective coatings: Applying a protective coating, such as a clear lacquer or special stainless steel protective spray, can create a barrier between the stainless steel and external factors that could cause rust. These coatings provide an extra layer of protection and help maintain the appearance and durability of stainless steel strips. 5. Avoid exposure to saltwater or high humidity: Stainless steel can be more susceptible to rusting in environments with high humidity or exposure to saltwater. If possible, limit the exposure of stainless steel strips to these conditions. If it is not possible to avoid such environments, taking extra precautions, such as more frequent cleaning and using appropriate protective coatings, becomes even more important. By following these preventive measures, you can significantly reduce the risk of rust formation on stainless steel strips and ensure their longevity and aesthetic appeal.

- Q: Are 111 stainless steel strips resistant to intergranular corrosion?

- 111 stainless steel strips exhibit resistance to intergranular corrosion. This type of stainless steel, known as austenitic stainless steel, contains elevated levels of chromium and nickel, resulting in exceptional corrosion resistance. The carbon content and the presence of stabilizing elements like titanium or niobium determine the intergranular corrosion resistance in stainless steel. 111 stainless steel strips typically possess low carbon content, preventing the formation of chromium carbide precipitates along the grain boundaries and reducing susceptibility to intergranular corrosion. Furthermore, the abundant chromium and nickel content in 111 stainless steel encourages the formation of a protective oxide layer on the surface, further enhancing its corrosion resistance. As a result, 111 stainless steel strips are widely acknowledged for their strong resistance to intergranular corrosion.

- Q: Do you have stainless steel with magnetic?

- Ferritic stainless steel is generally magnetic, austenitic stainless steel is generally non-magnetic. So we can't generalize.

- Q: Can 111 stainless steel strips be coated with anti-corrosion paints?

- 111 stainless steel strips can indeed be coated with anti-corrosion paints. Stainless steel possesses remarkable resistance to corrosion; nonetheless, there are specific environments or situations where supplementary safeguarding measures may become necessary. Anti-corrosion paints are specifically formulated to furnish an additional shield against corrosion by establishing a barrier between the steel surface and its surrounding environment. The application of these paints can effectively impede rusting, staining, as well as various other forms of corrosion on stainless steel. It is crucial to guarantee the compatibility of the chosen paint with stainless steel and adhere to appropriate application procedures to attain the best possible outcomes.

- Q: Can stainless steel strips be used in medical instrument manufacturing?

- Yes, stainless steel strips can be used in medical instrument manufacturing. Stainless steel is a common material used in the medical industry due to its excellent properties such as corrosion resistance, high strength, and ability to withstand high temperatures. These properties make stainless steel strips suitable for a wide range of medical instruments, including surgical tools, dental instruments, implantable devices, and diagnostic equipment. Additionally, stainless steel is easy to clean and sterilize, which is crucial in maintaining a sterile environment in medical facilities. Therefore, stainless steel strips are widely used in medical instrument manufacturing due to their durability, reliability, and hygienic qualities.

- Q: How do you prevent galvanic corrosion of stainless steel strips?

- To prevent galvanic corrosion of stainless steel strips, there are several measures that can be taken: 1. Proper material selection: Choose stainless steel strips that have a high resistance to galvanic corrosion. Austenitic stainless steels, such as grades 304 and 316, are commonly used due to their excellent corrosion resistance properties. 2. Insulation and isolation: Ensure that the stainless steel strips are insulated or isolated from other metals that have dissimilar electrochemical properties. This can be achieved by using non-conductive gaskets, insulating coatings, or by placing a barrier between the stainless steel and the dissimilar metal. 3. Avoid direct contact with electrolytes: Galvanic corrosion occurs when there is an electrolyte present, such as moisture or certain chemicals. To prevent this, it is important to avoid direct contact between the stainless steel strips and these electrolytes. This can be done by using protective coatings, keeping the strips dry, or using gaskets or seals to create a barrier. 4. Cathodic protection: Implementing cathodic protection can help prevent galvanic corrosion by making the stainless steel strips the cathode in the galvanic cell. This can be achieved through methods such as sacrificial anodes or impressed current systems. By supplying a more easily corroded metal to act as an anode, the stainless steel strips are protected from galvanic corrosion. 5. Regular maintenance and cleaning: Proper maintenance and cleaning of the stainless steel strips can help prevent the build-up of contaminants and corrosive substances that can accelerate galvanic corrosion. Regular inspection and cleaning can help identify and address any potential issues before they become major problems. By following these preventive measures, the risk of galvanic corrosion of stainless steel strips can be significantly reduced, ensuring their long-term durability and performance.

- Q: Are stainless steel strips suitable for architectural cladding?

- Architectural cladding can benefit from the use of stainless steel strips. This material is known for its versatility and durability, making it a suitable choice for this purpose. One advantage of stainless steel is its excellent resistance to corrosion, which makes it well-suited for outdoor applications. It can withstand challenging weather conditions, moisture, and exposure to chemicals, ensuring that the cladding remains strong and durable over time. Another advantage of stainless steel is its sleek and modern appearance, which adds an aesthetic appeal to buildings. It can be finished in different ways, such as brushed, polished, or embossed, allowing architects and designers to achieve various visual effects and styles. Furthermore, stainless steel strips come in a wide range of sizes, thicknesses, and shapes, providing flexibility in design and installation. They can be easily cut, formed, and welded to fit specific architectural requirements, making them suitable for both large-scale projects and intricate detailing. Moreover, stainless steel is a low-maintenance material that requires minimal upkeep. It is resistant to staining, scratching, and fading, reducing the need for frequent cleaning or repairs. This characteristic makes it a cost-effective choice for architectural cladding. In conclusion, stainless steel strips offer several advantages for architectural cladding, including corrosion resistance, aesthetic appeal, versatility, and low-maintenance properties. They provide architects and designers with a reliable and visually appealing solution for enhancing the exterior of buildings.

- Q: Can stainless steel strips be used in the automotive exhaust system?

- Yes, stainless steel strips can be used in the automotive exhaust system. Stainless steel is a popular material choice for exhaust systems due to its excellent resistance to corrosion, high temperature strength, and durability. Stainless steel strips can be used to fabricate various components of the exhaust system, including pipes, mufflers, and catalytic converters. These strips can withstand the harsh conditions of the exhaust system, such as high temperatures, exposure to moisture, and the presence of corrosive gases. Additionally, stainless steel offers good aesthetics and can be easily formed and welded, making it a versatile material for automotive exhaust systems.

Send your message to us

Stainless Steel Coil 304 Hot Rolled Surface No.1

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords