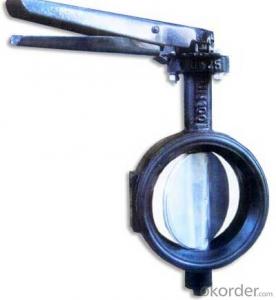

Stainless Steel ,Carbonsteel Wafer Butterfly Valve,Oblea de la Valvula tipo Mariposa

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Veneer Cases |

| Delivery Detail: | According to the requirements of the guests |

Specifications

oblea de la valvula tipo mariposa

Product name:wafer type butterfly valve

ANSI DIN BS JIS GB design

1.Product name:wafer type butterfly valve , oblea de la valvula tipo mariposa

2.Cast Iron Body

3.Butterfly Valve

4. Size: 2"-24"

Butterfly valve, also called the flap valve is a kind of simple structure of the regulator, can be used for low pressure pipeline medium of switch control butterfly valve is closed (disc or disc) is a disc, shaft rotation around the valve to open and close a valve, the valve can be used to control air, water, steam, all kinds of corrosive medium, mud, oil, liquid metal and radioactive medium such as various types of fluid flow.Mainly in the line cut off and throttling effect.Butterfly valve opening and closing is a disc-shaped butterfly plate, the body rotation around its own axis, so as to achieve the aim of opening and closing or adjust.

Butterfly plate by the stem drive, if turn 90 °, can complete an opening and closing.Change the butterfly plate deflection Angle, can control the flow of medium.

Use condition and medium: butterfly valve is suitable for generator, gas, natural gas, liquefied petroleum gas, city gas, cold hot air smelting, chemical industry and power generation, environmental protection, such as, building water supply and drainage engineering system in conveying all kinds of corrosive fluid pipe, non corrosive, used to adjust and block the flow of the medium.

FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What do you mean, handle, butterfly valve, hard back and soft back?

- Hello, soft sealing butterfly valve is generally divided into skeleton, seat and frameless valve seat, the skeleton of the general material: resin, aluminum, iron.. Etc.. With back seat is on the back of the vulcanized rubber, without skeleton, valve seat is rubber.

- Q: Does the wet alarm valve group need to install the signal butterfly valve?

- Wet alarm valve at the front of the signal butterfly valve with the main floor of the main role of the butterfly valve, first, maintenance, and two is the prompt sprinkler system, there is a signal butterfly valve closed, should be repaired as soon as possible.

- Q: How many kinds of butterfly valves are there?

- 1. according to the structure classification (1) Central sealing butterfly valve (2) single eccentric sealed butterfly valve (3) double eccentric sealed butterfly valve (4) three eccentric sealed butterfly valve2., according to the sealing material classification (1) soft sealing butterfly valve. (2) metal hard sealing butterfly valve.3. according to the form of sealing classification (1) forced sealing butterfly valve (2) pressure sealed butterfly valve.4. classification according to working pressure (1) vacuum butterfly valve. 2) low pressure butterfly valve. (3) medium pressure butterfly valve. (4) high pressure butterfly valve. (5) ultra high pressure butterfly valve.5. classification by working temperature (1) high temperature butterfly valve. (2) medium temperature butterfly valve. (3) normal temperature butterfly valve. (4) low temperature butterfly valve. (5) ultra low temperature butterfly valve.

- Q: I am confused as to the answer of this question. Please help.Indicate the status of the mitral, tricuspid and semilunar valves (whether they are open or closd) during the various phases of the cardiac cycle. Discuss the pressure in each of the relevant chambers or blood vessels during the phases with reference to the opening or closing of the valves.

- A heartbeat is a two-part pumping action that takes about a second. As blood collects in the upper chambers (the right and left atria), the heart's natural pacemaker (the SA node) sends out an electrical signal that causes the atria to contract. This contraction pushes blood through the tricuspid and mitral valves into the resting lower chambers (the right and left ventricles). This part of the two-part pumping phase (the longer of the two) is called diastole. The second part of the pumping phase begins when the ventricles are full of blood. The electrical signals from the SA node travel along a pathway of cells to the ventricles, causing them to contract. This is called systole. As the tricuspid and mitral valves shut tight to prevent a back flow of blood, the pulmonary and aortic valves are pushed open. While blood is pushed from the right ventricle into the lungs to pick up oxygen, oxygen-rich blood flows from the left ventricle to the heart and other parts of the body. After blood moves into the pulmonary artery and the aorta, the ventricles relax, and the pulmonary and aortic valves close. The lower pressure in the ventricles causes the tricuspid and mitral valves to open, and the cycle begins again. This series of contractions is repeated over and over again, increasing during times of exertion and decreasing while you are at rest. The heart normally beats about 60 to 80 times a minute when you are at rest, but this can vary. As you get older, your resting heart rate rises. Also, it is usually lower in people who are physically fit.

- Q: Import electric butterfly valve which brand is more reliable?

- Recommend Sichuan Ding Heng petroleum machinery company sales agent SPM butterfly valve and FMC butterfly valve, we are partners for many years, have been working together are very happy.

- Q: What is the meaning of the D341*5-10 / 16ZB1 turbine butterfly valve flange said?

- D: for clamp, 3: turbine head 4: flange connection 1: vertical plate X5: Ding fine rubber 10/16: nominal pressure Z: gray cast iron valve body, B1: valve plate material is ductile iron

- Q: How does the pneumatic butterfly valve control the angle of opening?

- This is really not good, control seems to be pneumatic defects, can only rely on the feeling

- Q: What are single eccentric and double eccentric in butterfly valves? What's the difference, please explain in detail?

- Eccentric butterfly valve is divided into single eccentric butterfly valve, double eccentric butterfly valve, three eccentric butterfly valve, variable eccentric butterfly valve.Single eccentric butterfly valve: extrusion problems, address concentric butterfly valve and valve seat of the resulting in a single eccentric butterfly valve, the structural characteristics of the stem axis deviated from the disc center, so that the butterfly is no longer a rotary bottom plate, axial dispersion, reduce the excessive squeezing and the lower end of the seat of the butterfly board.

- Q: Butterfly D371X5-16ZB1 what does each letter stand for?

- Daily valve pressThe regular model is out of step with you. I can only explain the regularD371X5-16ZB1D is butterfly valve3 is the turbine drive7 is the clamp connection1 is the display opening signX is a rubber seal16 is 16 kg pressureI don't know the other superfluous letters

- Q: butterfly valves d7a1x5

- D- valve type (butterfly valve), 7- connection mode (to clamp), A- valve shape mode (A), 1- structure form (vertical plate), X5- valve seat sealant species (Ding Qing, NBR)

Send your message to us

Stainless Steel ,Carbonsteel Wafer Butterfly Valve,Oblea de la Valvula tipo Mariposa

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords